Micro fluid control detection device based on surface-enhanced Raman scattering active substrate

A surface-enhanced Raman, active substrate technology, applied in Raman scattering, processes for producing decorative surface effects, electrical solid devices, etc. Cumbersome, restrictions and other issues, to achieve the effect of promoting research and production development, improving production efficiency and integration, and reducing industrial production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

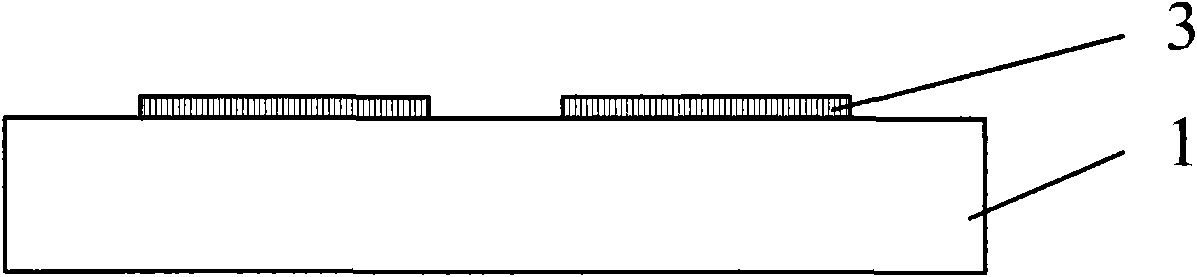

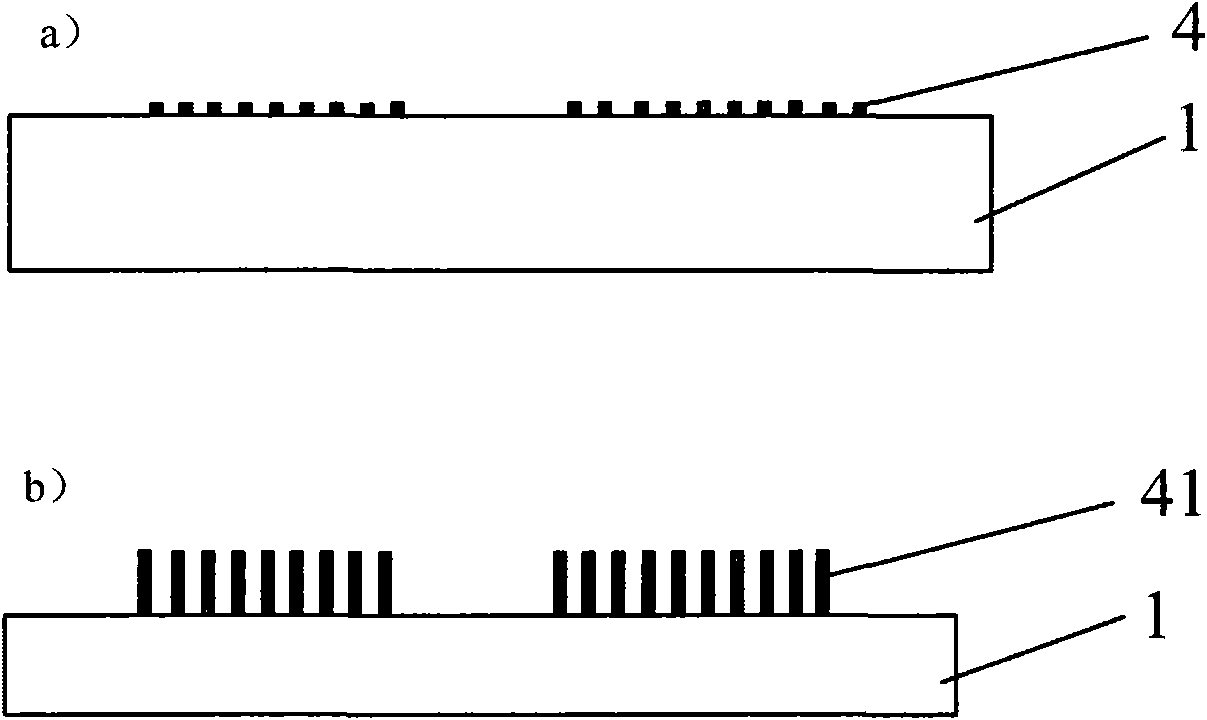

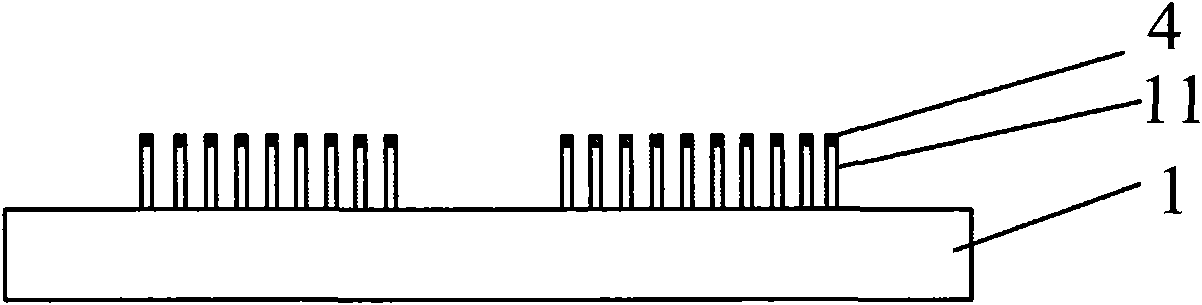

[0046] Example 1. Preparation of microfluidic detection device based on SERS substrate

[0047] 1) Preparation of SERS active substrate

[0048] Spin-coat RZJ-304 positive photoresist with a thickness of 1 μm on the surface of the silicon substrate 1 (substrate a), pre-bake it in an oven at 98°C for 15 minutes, use a wavelength of 365nm, and an intensity of 5.4mW / cm 2 The ultraviolet light is irradiated for 5s through the mask plate, and developed in the developer of RZJ-304 positive photoresist for 30s to form a photoresist pattern in the shape of a microchannel; put the silicon substrate 1 with the photoresist pattern into Power is 250W, oxygen flow rate is in the oxygen plasma bombardment cavity of 30sccm / min, carry out 5 minutes bombardment to photoresist, prepare nanoparticle structure on silicon substrate 1; The silicon substrate with nanoparticle structure 1 Put in a power of 400W, SF 6 and C 4 f 8 In the cavity of a reactive ion etching machine with a flow rate of ...

Embodiment 2

[0051] Example 2. Preparation of microfluidic detection device based on SERS substrate

[0052] 1) Preparation of SERS active substrate

[0053] Spin-coat Shipley SPR positive photoresist with a thickness of 5 μm on the surface of the silicon substrate 1 (substrate a), pre-bake it in an oven at 98°C for 15 minutes, use a wavelength of 365nm, and an intensity of 5.4mW / cm 2 The ultraviolet light is irradiated for 60s through the mask, and developed in the developer of Shipley SPR positive photoresist for 90s to form a photoresist pattern in the shape of a microchannel; the silicon substrate 1 with the photoresist pattern is put into the power In an oxygen plasma bombardment cavity with an oxygen flow rate of 250W and an oxygen flow rate of 30 sccm / min, the photoresist is bombarded for 25 minutes to prepare a nanoparticle structure on the substrate; the silicon substrate 1 with the nanoparticle structure is placed in Power is 400W, SF 6 and C 4 f 8 In the cavity of a reactive...

Embodiment 3

[0055] Example 3. Preparation of microfluidic detection device based on SERS substrate

[0056] 1) Preparation of SERS active substrate

[0057] Spin-coat Shipley AZ series positive photoresist with a thickness of 20 μm on the surface of the silicon substrate 1 (substrate a), and use a wavelength of 365 nm and an intensity of 4.5 mW / cm 2 The ultraviolet light is irradiated through the mask plate for 400s, and developed in the developer of Shipley AZ series positive photoresist for 600s to form a photoresist pattern in the shape of a microchannel; put the silicon substrate 1 with the photoresist pattern into Power is 250W, oxygen flow rate is 30sccm / min oxygen plasma bombardment cavity, carry out 100 minutes bombardment to photoresist, prepare nanoparticle structure on the substrate; Put the silicon substrate 1 with nanoparticle structure The input power is 400W, SF 6 and C 4 f 8In the cavity of a reactive ion etching machine with a flow rate of 40 and 90 sccm / min, the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com