Method for pressing semicoke powder used for producing calcium carbide

A compression molding, calcium carbide technology, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of difficult temperature, unreachable, low heat energy utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

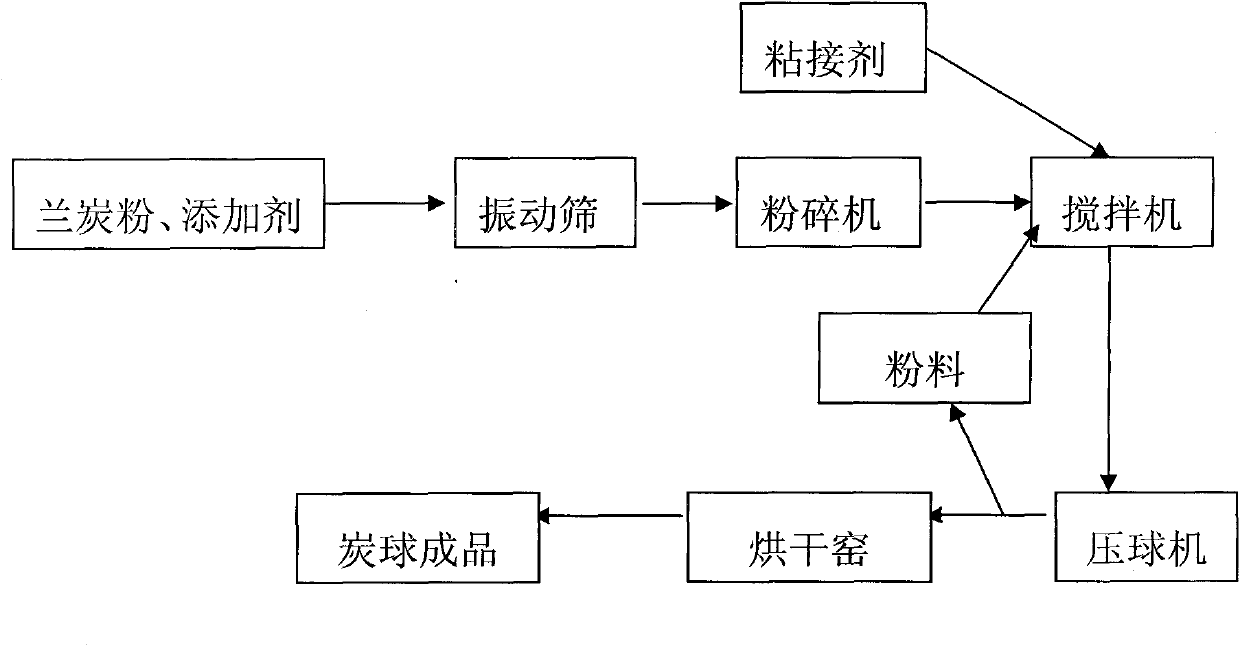

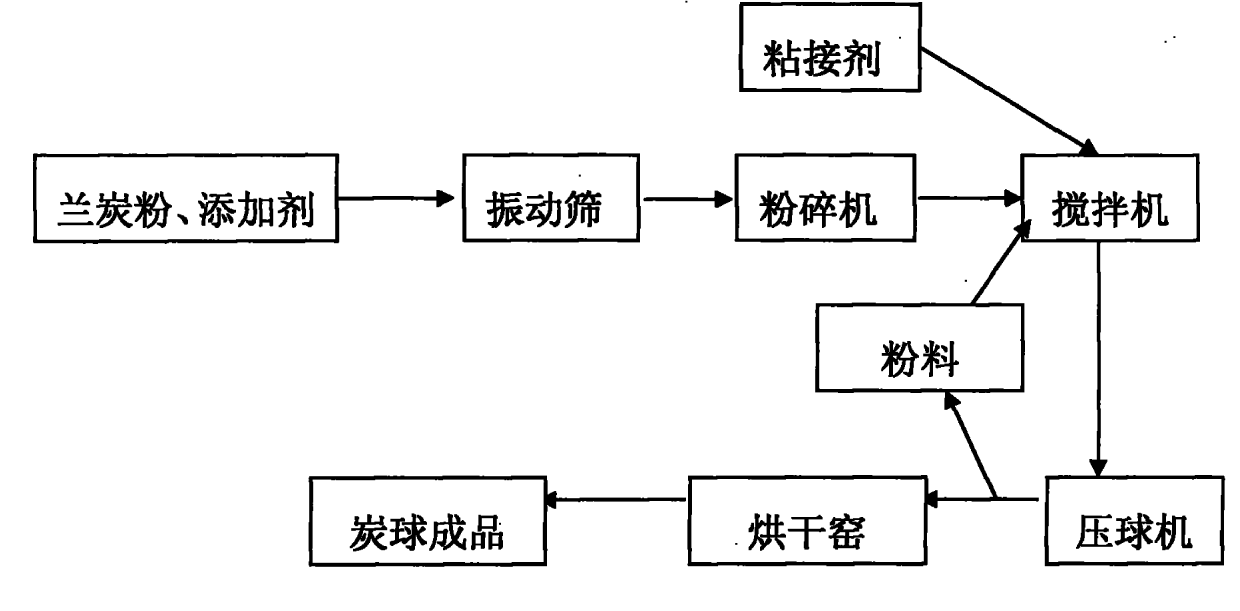

Image

Examples

Embodiment Construction

[0028] The present invention mixes 82%-91% blue charcoal powder, 3%-9% additive fat coal and 2%-11% binder by weight percentage, and adds the mixture to a mixer at normal temperature for mixing and stirring for 2- The stirring time is about 5 minutes, and finally the ball is pressed into shape, and the finished product is finished after drying.

[0029] The adhesive is mixed with 20-30% caustic soda sodium hydroxide solution, 20-30% urea solution, and 40-60% cornstarch by weight percentage, and 60°C-80°C hot water is added when mixing That is, the blue charcoal powder molding adhesive; wherein the concentration of sodium hydroxide solution is 0.1%-5%, and the concentration of urea solution is 0.1%-5%. Add less hot water than cornstarch, and when combined, the mixture should be thick enough.

[0030] JS500 forced mixer is selected, and the mixture of pulverized semi-coal powder, fat coal and binder is stirred for about 2-5 minutes at room temperature, so that the content of bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com