Optical biosensor for detecting brain natriuretic peptide (BNP) and preparation method of reagent thereof

A biosensor and brain natriuretic peptide technology, applied in the field of biosensing, can solve the problems of the preparation method of the brain natriuretic peptide optical biosensing technology, which affects the detection speed and sensitivity, and achieve simple and fast detection, easy promotion and operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

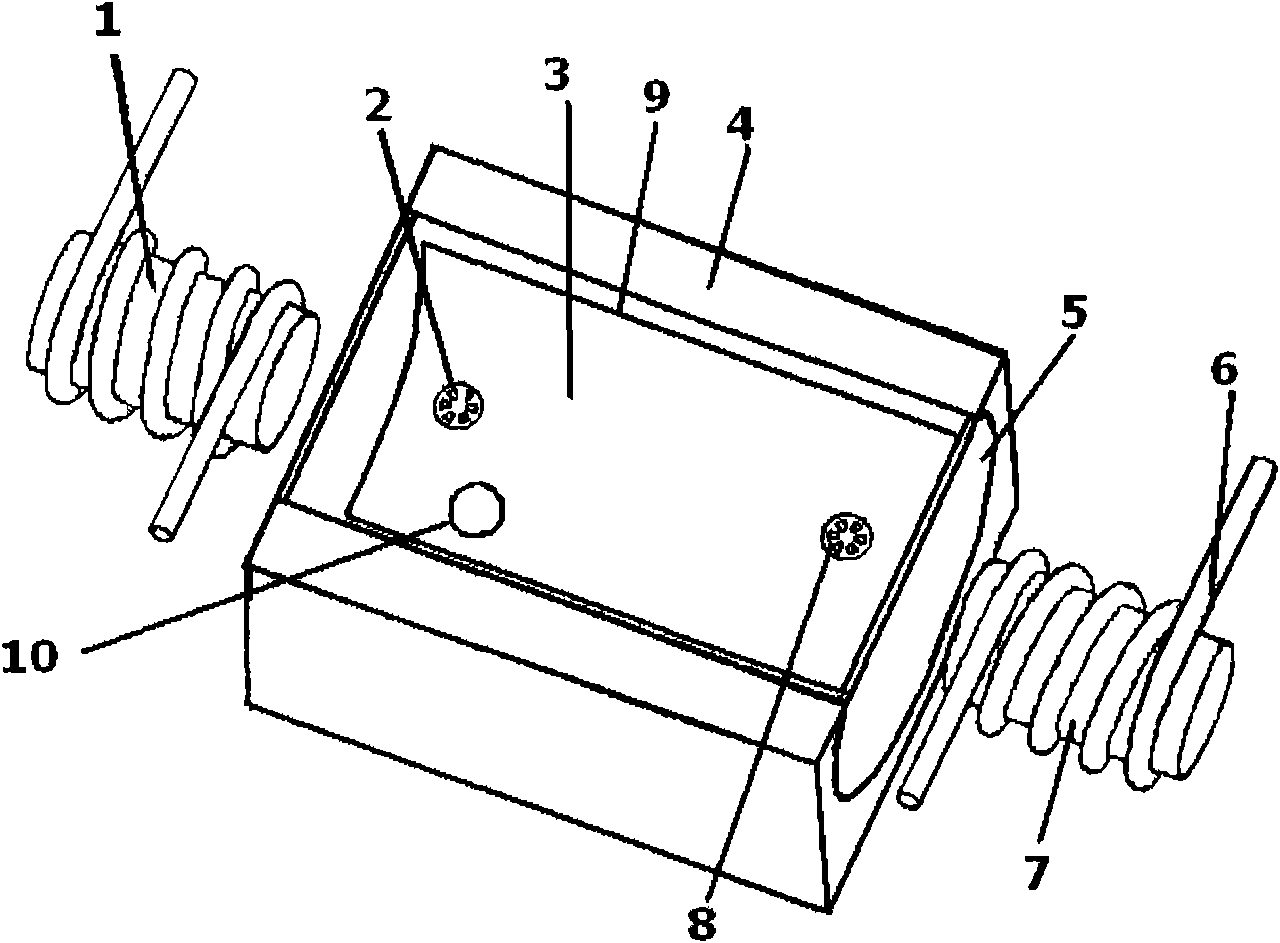

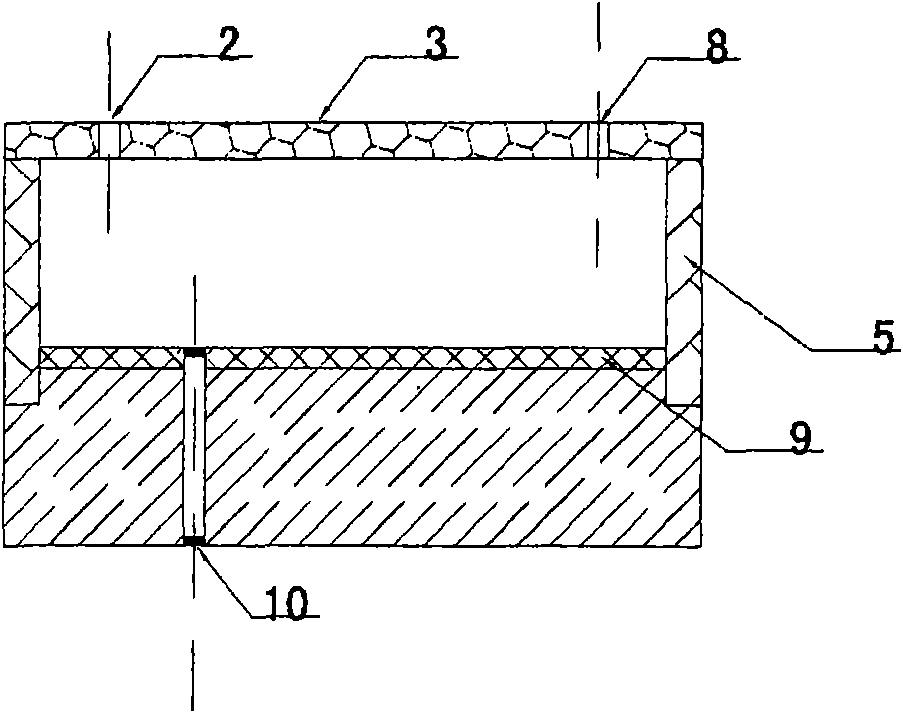

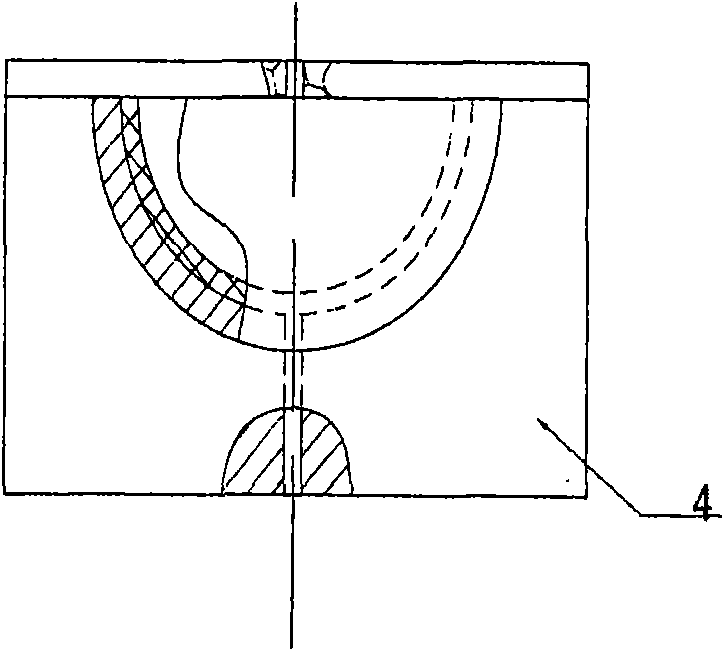

[0042] figure 1 2(a), (b), and (c) are schematic diagrams of the magnetic nanoprobe-based BNP optical biosensor designed by the present invention. First, a micro-channel with a length of 20 mm, a width of 5 mm, and a depth of 4 mm is etched on a silicon base using a micro-electro-mechanical system (MEMS) process, and the top of the channel is bonded with a glass with excellent light transmission ( A cover sheet) 3, a sample injection hole 2 and a sample injection hole 8 are arranged on the glass (cover sheet) 3, and a sample outlet 10 communicating with the microchannel is arranged at the bottom of the silicon base 4. Assemble a polymer carboxymethylcellulose (CMC) nanomaterial layer 9 on the inner surface of the channel in the reaction zone, place it in a drying oven at 37° C. for 30 minutes, and take it out for use.

[0043] Add reaction reagent then, drip 50 μ l brain natriuretic peptide magnetic nanoprobe solution from injection hole 2, drip 20 μ l brain natriuretic pepti...

Embodiment 2

[0045] 1) Preparation of BNP-specific probes

[0046] Take 200 μl of amino-terminal magnetic nanoparticles and place them in a 2 ml centrifuge tube, add 600 μl of 0.03 mol / L pyridine solution, and shake to mix. Remove the supernatant by magnetic separation with a magnetic stand, and repeat the above operation twice. Then, 200 μl of 10% glutaraldehyde was added to the centrifuge tube, and placed in a constant temperature shaker at 37° C. at 220 rpm for 30 minutes to shake and react for uniform mixing. Magnetic separation was performed to remove unreacted glutaraldehyde, and finally washed three times with 200 μl Tris-HCl buffer solution (0.05 mol / L; pH=7.10-9.00).

[0047] Dissolve the BNP antibody in PBS buffer, and prepare an antibody solution with a concentration of 0.22-2.0 mg / mL. Take 400 μl of the BNP antibody solution and add it to 200 μl of the above-treated magnetic nanoparticles, and shake and react at 180 rpm in a constant temperature shaker at 37° C. for 6 hours. ...

Embodiment 3

[0052] 1) Preparation of BNP-specific probes

[0053] Such as image 3 , use a pipette to pipette 200μl (equivalent to 1mg) of magnetic nanoparticles labeled with avidin on the surface, place them in a 2ml centrifuge tube, add 1000μl Tris-HCl buffer (containing 1mmol / LEDTA, 1mol / L NaCl, pH =7.4), shake gently to mix the magnetic particles, magnetically separate, and wash twice. The above-mentioned magnetic particles were dissolved with 100 μl of PBS buffer.

[0054] 100 μl of biotin-labeled BNP antibody was dissolved in 800 μl of Tris-HCl buffer, and the antibody concentration was 0.1875 mg / mL. The above antibody solution was added to the activated magnetic particles, placed in a shaker at 37°C and 150 rpm for 30 min, and subjected to magnetic separation, and the supernatant was removed. Add 1 ml of PBS buffer solution (containing 0.05% Tween-20 and 0.1% BSA) into the centrifuge tube after the coupling reaction, shake gently to mix, magnetically separate, and operate twice....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com