Preparation method of full optical fiber laser synthesizer

A laser synthesis and all-fiber technology, which is applied to laser components, lasers, cladding fibers, etc., can solve problems such as damage to coupling devices, reduce fusion or tapering, facilitate mass production, and achieve mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

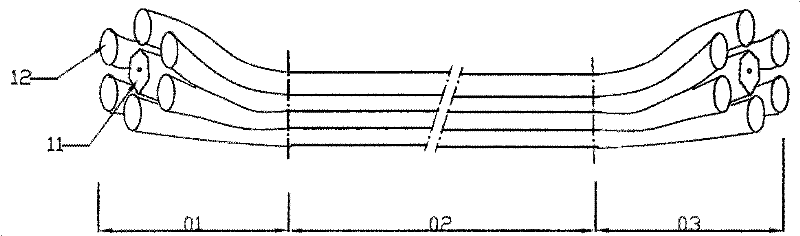

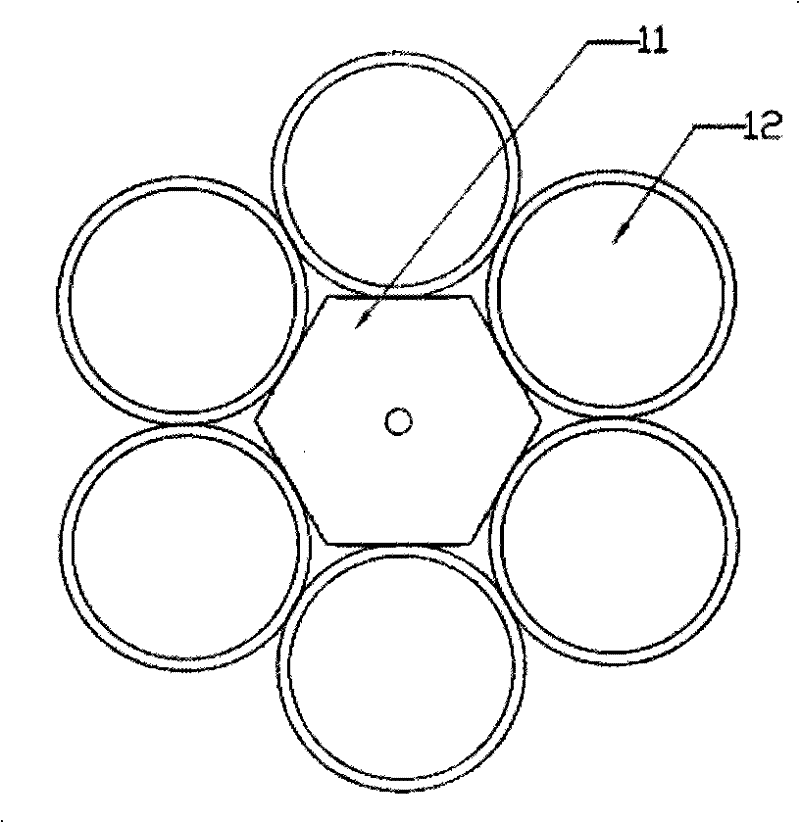

[0045] attached figure 1 Shown is the first embodiment of the all-fiber laser synthesis device of the present invention, which is a schematic diagram of the appearance. All the fibers in the fiber bundle have the same length, generally between 1 and 30 m, and the length of the fiber bundle is different according to the application of the fiber laser. The fiber bundle consists of 6 step-type multimode fibers and a rare earth-doped fiber. The rare-earth-doped optical fiber is located in the middle of the fiber bundle. In this embodiment, the rare-earth-doped optical fiber is an erbium-ytterbium co-doped optical fiber. Its inner cladding structure is a regular hexagon, and 6 multimode optical fibers are uniformly distributed around it. Their claddings are doped Fluoroquartz composition, the core layer is pure silicon composition, attached figure 2 A cross-sectional structure diagram of the fiber bundle is given. The core diameter / cladding diameter of the multimode optical fibe...

Embodiment 2

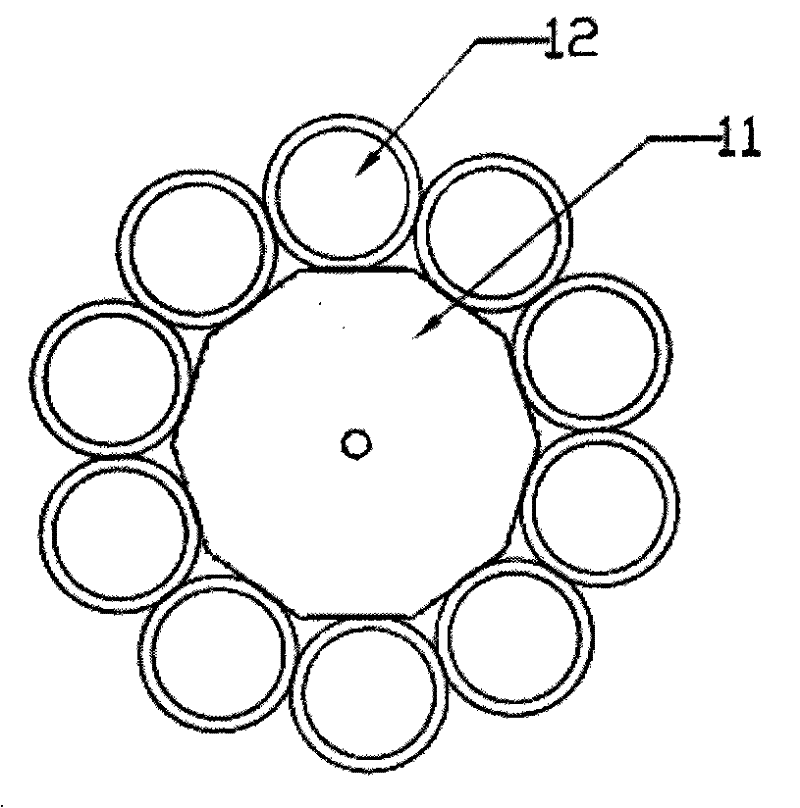

[0049] Outline schematic diagram of the second embodiment of the present invention and attached figure 1 Basically the same, the length of all the optical fibers in the fiber bundle is the same, the general length is between 1 and 30m, and the length of the fiber bundle is different according to the use of the fiber laser. The optical fiber bundle is composed of 10 step-type multimode fibers and a rare earth-doped fiber, the middle one is an ytterbium-doped fiber, and its inner cladding structure is a regular decagon, and 10 multimode fibers are evenly distributed around it. The layer is composed of fluorine-doped quartz, and the core layer is composed of pure silicon. image 3 A cross-sectional structure diagram of the fiber bundle is given. The core diameter / cladding diameter of the multimode optical fiber are both 105 / 125 μm or 200 / 220 μm or 400 / 440 μm, or other possible specifications, and the numerical aperture is 0.10-0.25. The core diameter of the rare earth-doped opt...

Embodiment 3

[0053] Outline schematic diagram of the third embodiment of the present invention and attached figure 1 Basically the same, the length of all the optical fibers in the fiber bundle is the same, the general length is between 1 and 30m, and the length of the fiber bundle is different according to the application of the fiber laser. The fiber bundle consists of 12 step-type multimode fibers and a rare earth-doped fiber. The middle one is an ytterbium-doped fiber. Its inner cladding structure is a regular hexagon, and 12 multimode fibers are evenly distributed around it. Their cladding It is composed of fluorine-doped quartz, and the core layer is composed of pure silicon. Two multimode fibers are arranged on each side of the inner cladding of the rare earth-doped optical fiber, with Figure 4 A cross-sectional structure diagram of the fiber bundle is given. The core diameter / cladding diameter of the multimode optical fiber are both 105 / 125 μm or 200 / 220 μm or 400 / 440 μm, or othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com