Method for preparing nanometer nickel powder by micro passage reaction vessel

A micro-channel reactor, nano-nickel powder technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problems of low intermittent production efficiency, microchannel blockage, etc., and achieve low cost of raw materials , The particle size distribution is narrow, and the effect of subsequent separation processing is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

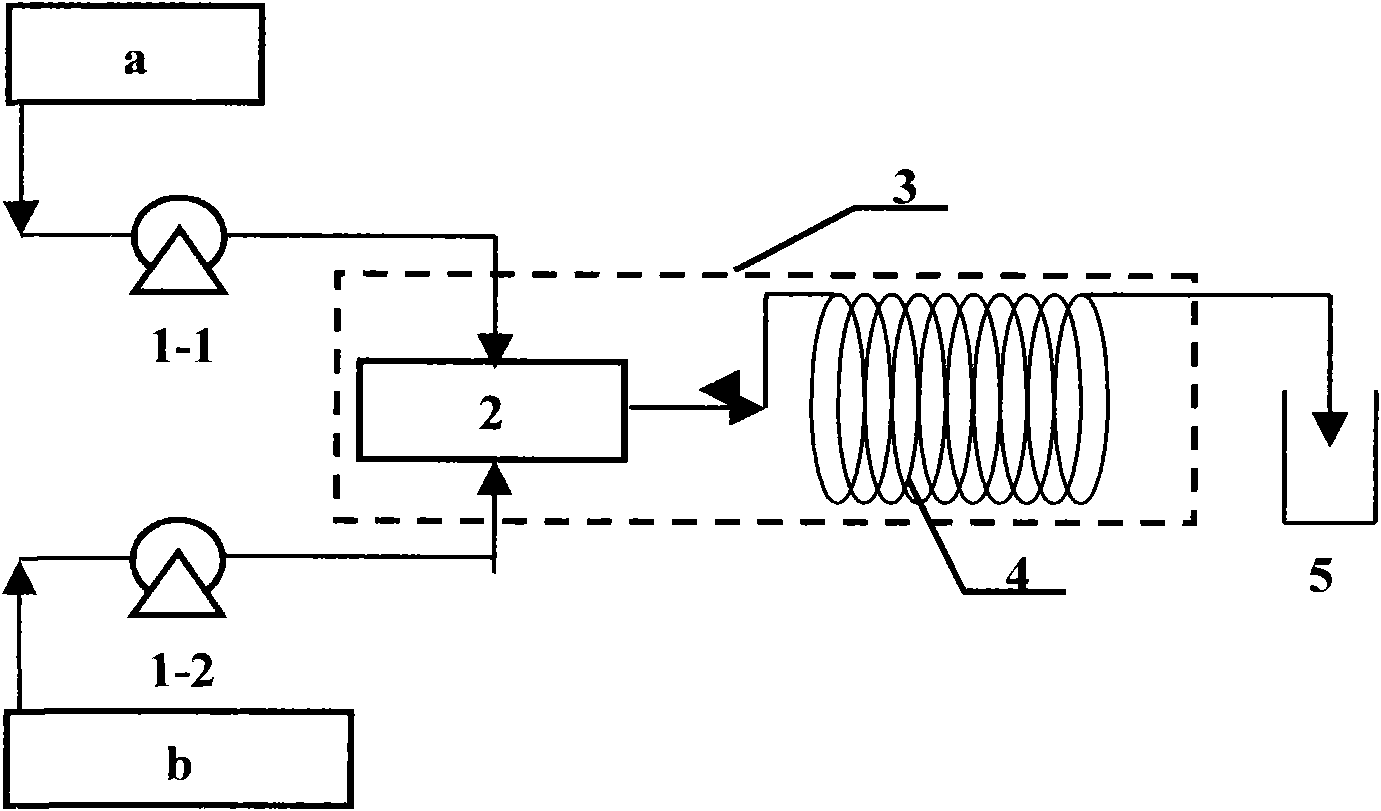

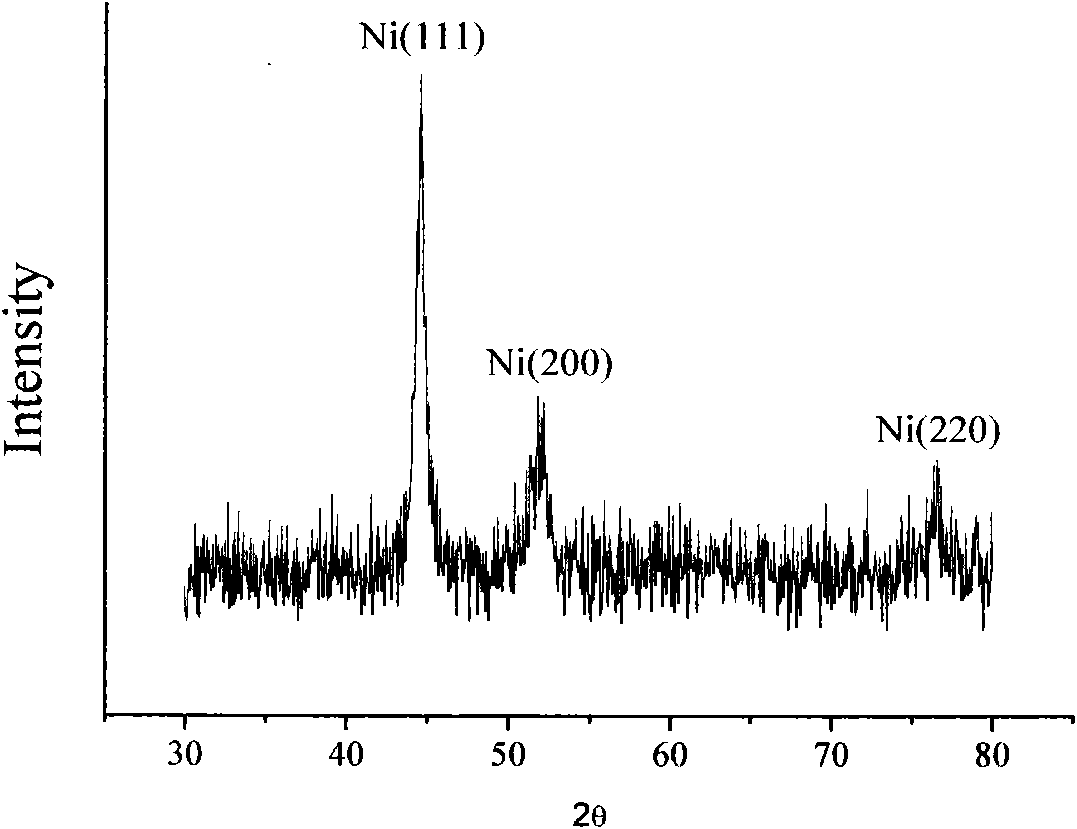

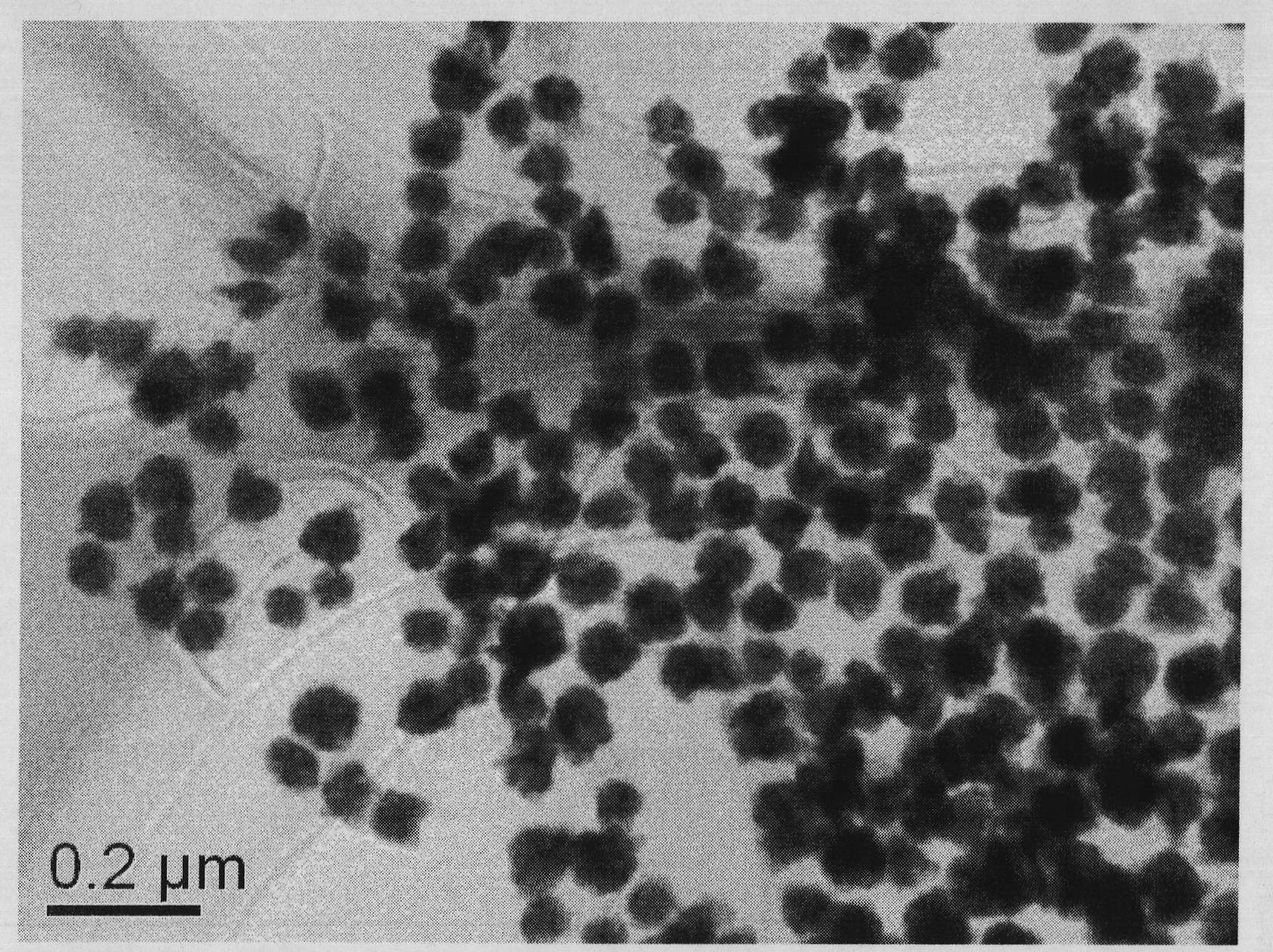

[0022] Dissolve 4.75g of nickel chloride in 50ml of ethanol to configure liquid A, add 4.71g of hydrazine hydrate and 3.2g of sodium hydroxide to 50ml of ethanol to configure liquid B, and inject liquid A and liquid B through a pump at a temperature of 70°C and a channel diameter of 100μm Mix in a micro-mixer (purchased from German IMM company), and after staying for 60ms, the feed liquid is directly injected into a microchannel reactor (purchased from Nanjing Wanqing Industrial Co., Ltd.) with a reaction temperature of 70 ° C and an inner diameter of 2 mm and stays for 3.5 minutes for reaction. , the product was collected, and the product was separated by centrifugation, washed to pH = 7, and stored in isolation from air. The XRD characterization shows that the product is nickel metal, and the nano-nickel average particle diameter obtained is 73nm, and the X-ray diffraction pattern (XRD) of the sample of this sample is as follows figure 2 Shown, TEM image see image 3 shown...

Embodiment 2

[0024] Dissolve 9.51g of nickel chloride in 100ml of ethanol to configure liquid A, add 8.83g of hydrazine hydrate and 6g of sodium hydroxide to 100ml of ethanol to configure liquid B, and inject liquid A and liquid B through a pump at a temperature of 70°C and a channel diameter of 100μm Mixed in a micro-mixer (purchased from IMM Company of Germany), after staying for 80ms, the feed liquid was directly injected into a microchannel reactor (purchased from Nanjing Wanqing Industrial Co., Ltd.) with a reaction temperature of 70 ° C and an internal diameter of 2 mm to react for 5 minutes. The products were collected, and the products were separated by centrifugation, washed to pH=6.5, and the obtained samples were kept in air isolation. The XRD characterization shows that the sample is nickel metal, and the average particle size of the obtained nano-nickel is 65nm. The FESEM figure of the sample is shown in Figure 4 shown.

Embodiment 3

[0026] Dissolve 2.08g of nickel chloride in 50ml of ethanol to configure liquid A, add 4.12g of hydrazine hydrate and 2.8g of sodium hydroxide to 50ml of ethanol to configure liquid B, and inject liquid A and liquid B through a pump at a temperature of 68°C. The channel diameter is Mix in a 50 μm micro-mixer (purchased from German IMM Company), and the feed liquid after staying for 50 ms is directly injected into a microchannel reactor (purchased from Nanjing Wanqing Industrial Company) with a reaction temperature of 68 ° C and an inner diameter of 2 mm (purchased from Nanjing Wanqing Industrial Company) for 4 min. React and collect the products, and the products are separated by centrifugation, washed to pH=6.5, and the obtained samples are kept in air isolation. The XRD characterization showed that the sample was nickel metal, and the average particle size of the obtained nano-nickel was 45nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com