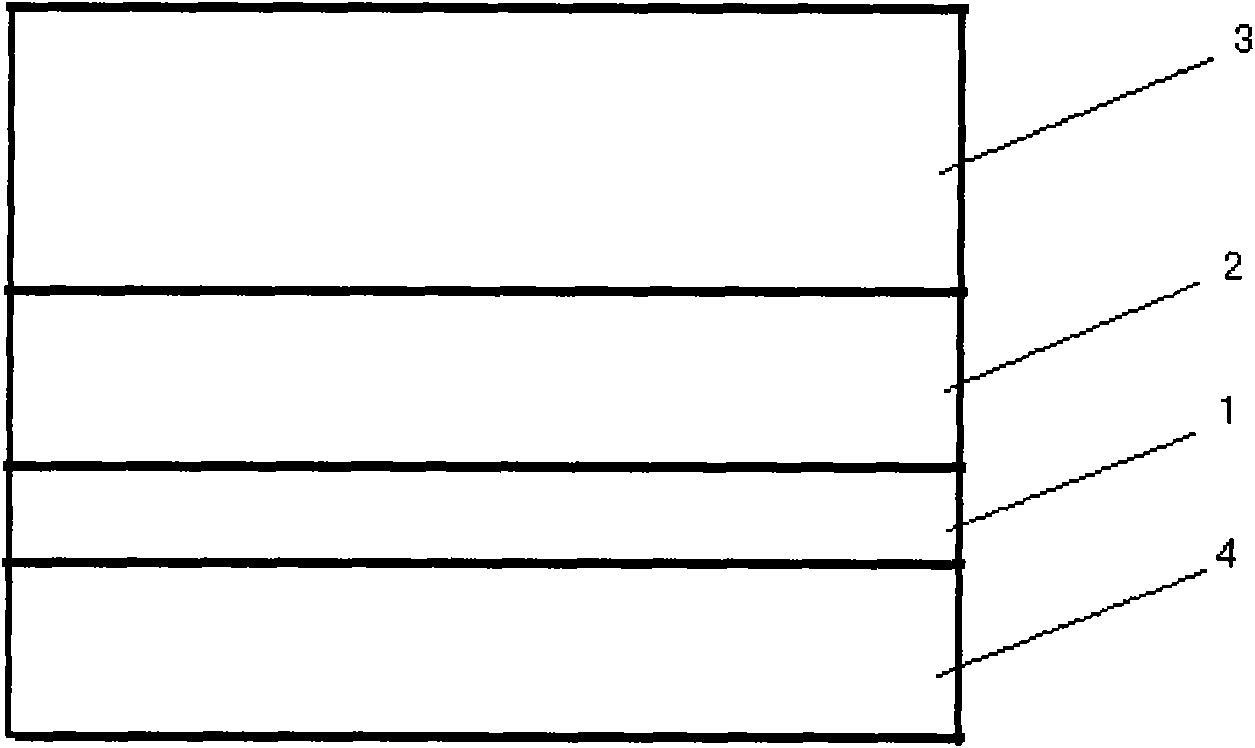

Ti-TiN-CNx gradient multilayer film and preparation method thereof

A multi-layer film, 1.ti-tin-cnx technology, applied in coatings, layered products, metal material coating processes, etc., can solve the problem of reducing the service life of wear-resistant film materials, limiting film growth thickness, and interface bonding Poor strength and other problems, to achieve the effect of reducing friction and wear, excellent friction reduction and wear resistance, biocompatibility, and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

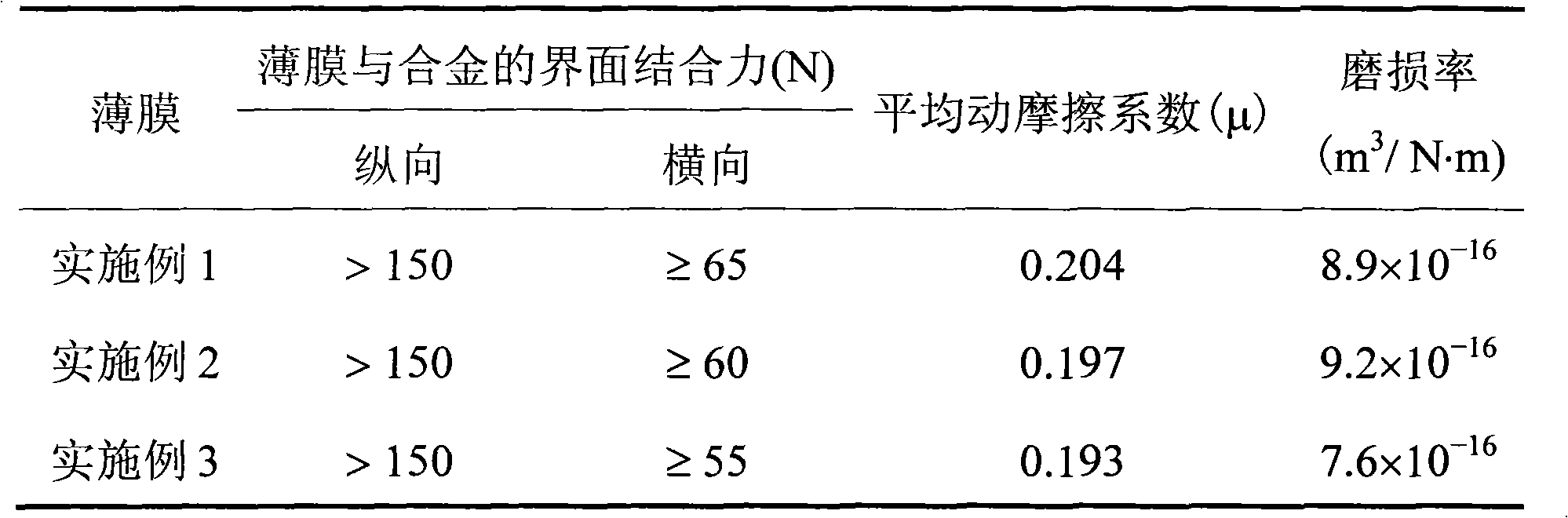

Embodiment 1

[0016] Preparation of Ti-TiN-CN by Unbalanced Magnetron Sputtering x Gradient multilayer film, the steps are as follows:

[0017] 1) Place a pure graphite target and a metal Ti target in two directions perpendicular to the horizontal plane and parallel to each other; place a titanium alloy substrate on the turntable in the magnetron sputtering reaction chamber, control the rotating speed of the turntable to 15rpm, and adjust the distance between the substrate and the target. The distance is 9cm;

[0018] 2) Vacuumize the reaction chamber to 3.0×10 -3 Pa, argon gas with a purity of 99.99% is introduced, and the flow rate of the argon gas is controlled at 30 sccm. Clean the target and substrate by sputtering with a titanium target current of 0.07A and a negative bias voltage of 220V for 30 minutes;

[0019] 3) Introduce pure argon gas, control the flow rate of argon gas to 30sccm, deposit a pure Ti bonding layer on the substrate with a titanium target current of 0.25A, and a ...

Embodiment 2

[0022] Preparation of Ti-TiN-CN by Unbalanced Magnetron Sputtering x Gradient multilayer film, the steps are as follows:

[0023] 1) Place a pure graphite target and a metal Ti target in two directions perpendicular to the horizontal plane and parallel to each other; place a titanium alloy substrate on the turntable in the magnetron sputtering reaction chamber, control the rotating speed of the turntable to 15rpm, and adjust the distance between the substrate and the target. The distance is 9cm;

[0024] 2) Vacuumize the reaction chamber to 3.0×10 -3 Pa, argon gas with a purity of 99.99% is introduced, and the flow rate of the argon gas is controlled at 30 sccm. Clean the target and substrate by sputtering with a titanium target current of 0.07A and a negative bias voltage of 220V for 30 minutes;

[0025] 3) Feed pure argon gas, control the flow rate of argon gas to 30 sccm, deposit a pure Ti bonding layer on the substrate with a titanium target current of 0.25A, and a bias...

Embodiment 3

[0028] Preparation of Ti-TiN-CN by Unbalanced Magnetron Sputtering x Gradient multilayer film, the steps are as follows:

[0029]1) Place a pure graphite target and a metal Ti target in two directions perpendicular to the horizontal plane and parallel to each other; place a titanium alloy substrate on the turntable in the magnetron sputtering reaction chamber, control the rotating speed of the turntable to 15rpm, and adjust the distance between the substrate and the target. The distance is 9cm;

[0030] 2) Vacuumize the reaction chamber to 3.0×10 -3 Pa, argon gas with a purity of 99.99% is introduced, and the flow rate of the argon gas is controlled at 30 sccm. Clean the target and substrate by sputtering with a titanium target current of 0.07A and a negative bias voltage of 220V for 30 minutes;

[0031] 3) Introduce pure argon gas, control the argon gas flow rate to 30 sccm, deposit a pure Ti bonding layer on the substrate with a titanium target current of 0.25A, and a bia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com