Environment friendly preparation process for producing propylene oxide through complexation extraction

A technology for the preparation of propylene oxide, which is applied in the direction of organic chemistry, can solve the problems of unrealized industrialization and a large amount of salty wastewater, and achieve the effects of easy industrial automation control, simple process and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

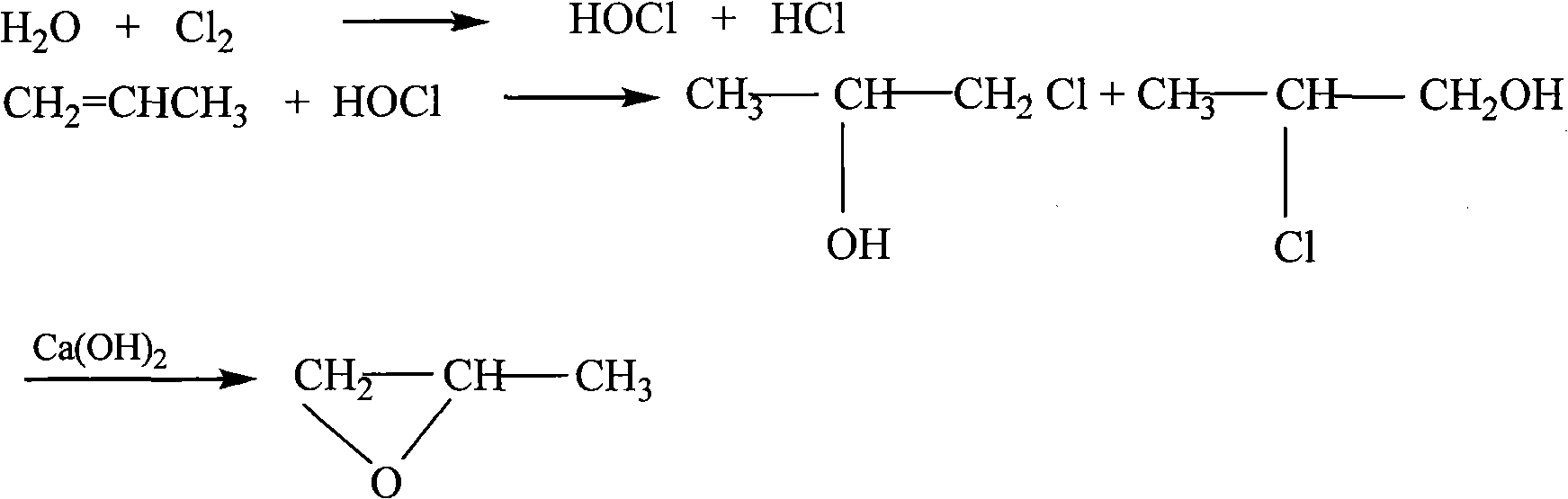

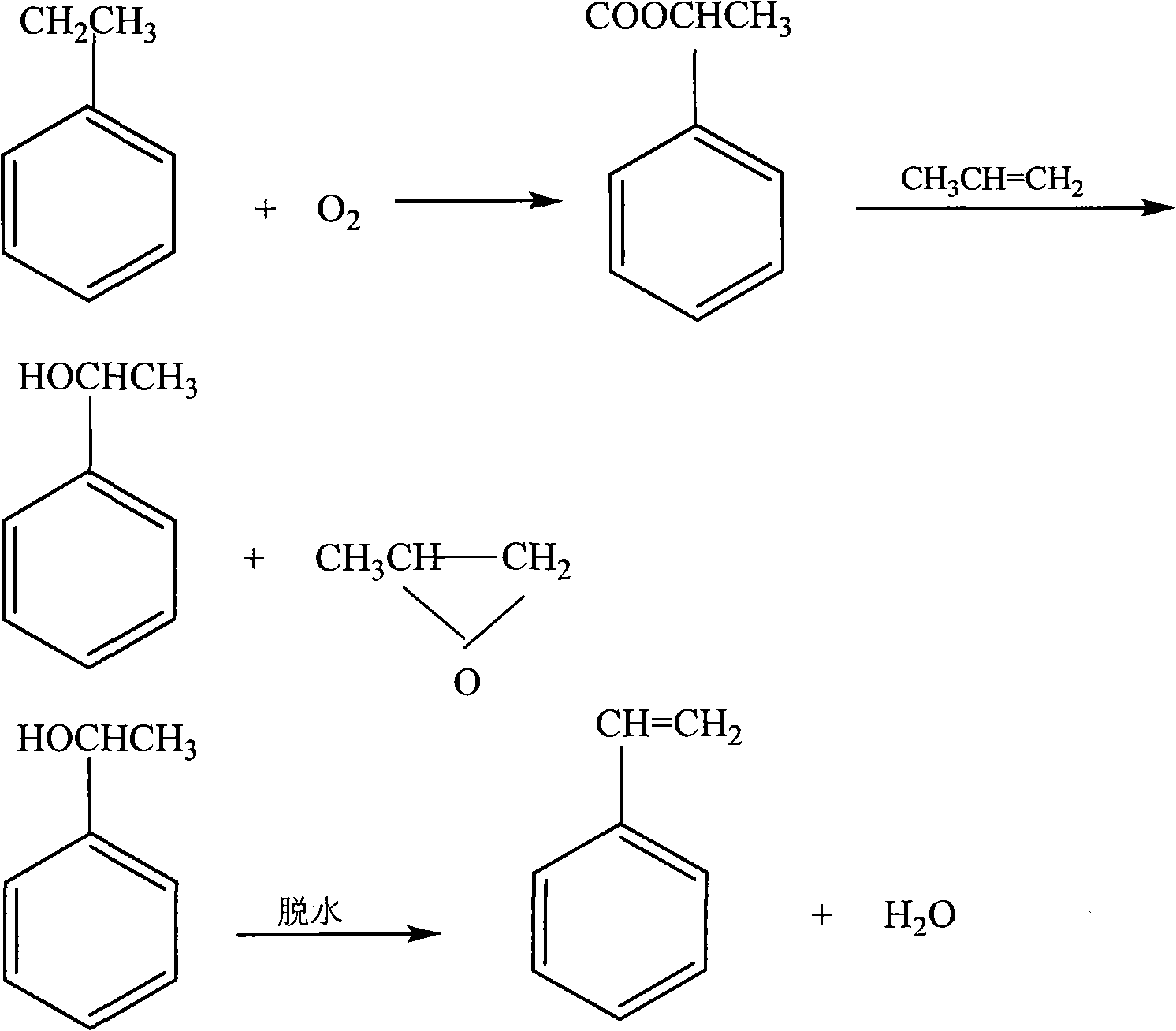

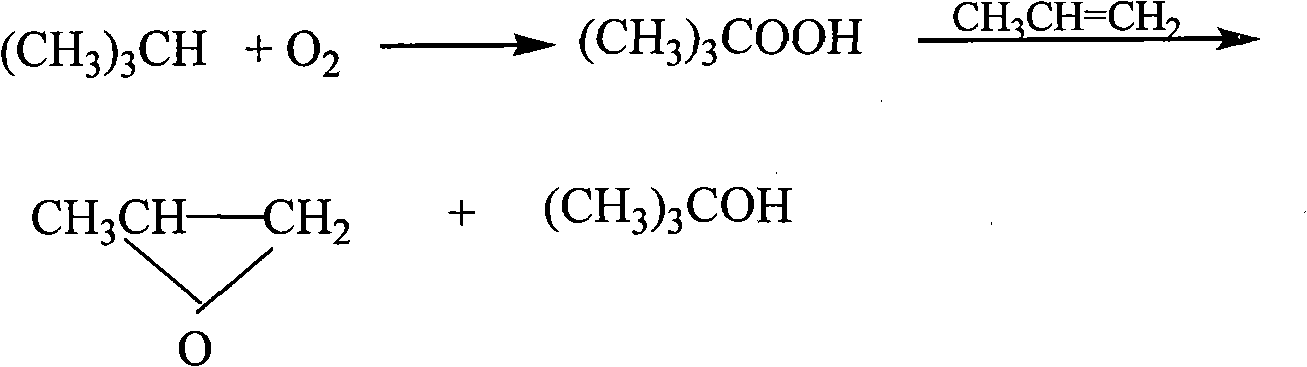

Method used

Image

Examples

Embodiment 1

[0038] An environment-friendly preparation process for producing propylene oxide by complex extraction, comprising the steps of:

[0039] (1) The monochloropropanol solution obtained by the traditional process, with a complex extraction agent (n-dodecane: N 235 : n-octanol volume ratio 5: 3: 2) to extract, its volume ratio is monochloropropanol solution: complex extractant=5: 3, three-stage extraction, monochloropropanol extraction rate is 95%, HCl The extraction rate is 98%, and the HCl content in the solution after extraction is 0.083%;

[0040] (2) The remaining chlorohydrination mother liquor after extraction is returned to the chlorohydrination reaction system, and the chlorohydrination reaction is not affected;

[0041] (3) The complex extract containing HCl and monochloropropanol is saponified with 20% (wt%) milk of lime (causing the residual alkali content of the mother liquor discharged from the bottom of the tower <0.5%); the crude propylene oxide is generated and o...

Embodiment 2

[0044] N in Example 1 235 Change trioctylamine into, n-dodecane: trioctylamine: n-octanol volume ratio is 1: 3: 2; One chloropropanol solution: complex extraction agent=5: 1 Its operating procedure is the same as embodiment 1, the result Basically consistent with embodiment 1.

Embodiment 3

[0046] Change the n-dodecane in Example 1 into n-decane, n-decane: tribenzylamine: n-octanol volume ratio is 10: 3: 2; monochloropropanol solution: complex extraction agent=1: 1 Other operation steps are with embodiment 1, and result is basically consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com