Cellulose/silver nano composite material and preparation method thereof

A composite material, silver nanotechnology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of strict preparation process conditions, unfavorable industrial promotion and application, long reaction time, etc., and achieve narrow particle size distribution range, Facilitate the promotion and use of industrialization, and the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

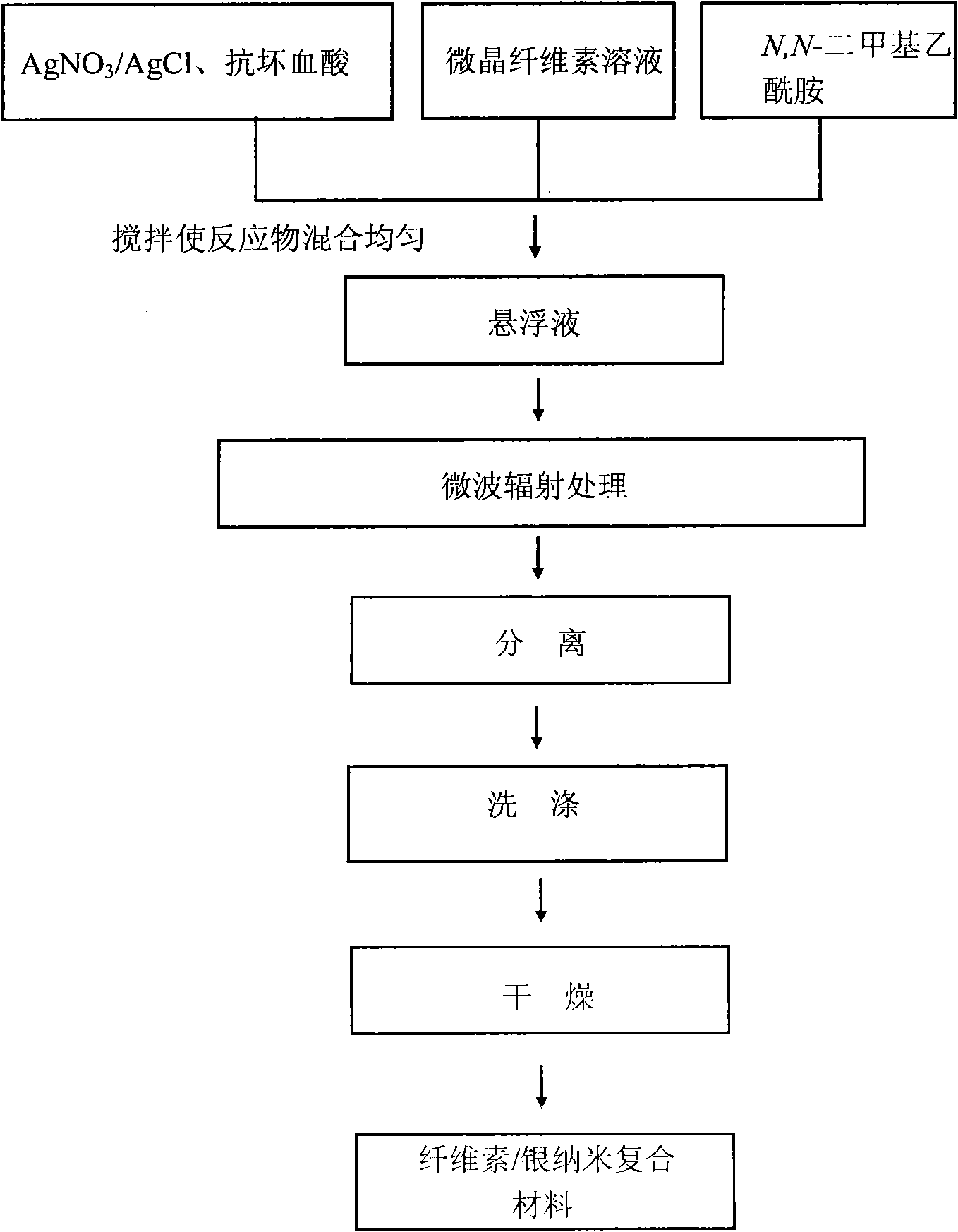

[0060] 1. Preparation of microcrystalline cellulose solution

[0061] Add 3.044g LiCl to 40mL N,N-dimethylacetamide to form a LiCl / N,N-dimethylacetamide solution, wherein the mass percentage of LiCl is 7.5%;

[0062] Add 2.848g of microcrystalline cellulose into the above solution, heat and stir at 90°C until a uniformly dispersed microcrystalline cellulose solution is obtained, wherein the molecular weight range of the microcrystalline cellulose is: 34843-38894.

[0063] 2. Preparation of cellulose / silver nanocomposites

[0064] 1) Preparation of suspension

[0065] First, 5 mL of microcrystalline cellulose solution was added to 30 mL of N,N-dimethylacetamide, and then 0.338 g of AgNO 3 and 3.000g of ascorbic acid were added therein, stirred evenly, until there was no precipitation, and a suspension was made;

[0066] 2) Microwave radiation treatment

[0067] The suspension was put into a microwave reactor (Beijing Xianghu Technology Development Co., Ltd., model: XH100B),...

Embodiment 2

[0074] Except that the amount of silver chloride used in the preparation of the cellulose / silver nanocomposite was 0.287g, the amount of ascorbic acid was 3.522g, the microwave radiation treatment temperature was 180°C, and the treatment time was 10min, the rest was the same as in Example 1.

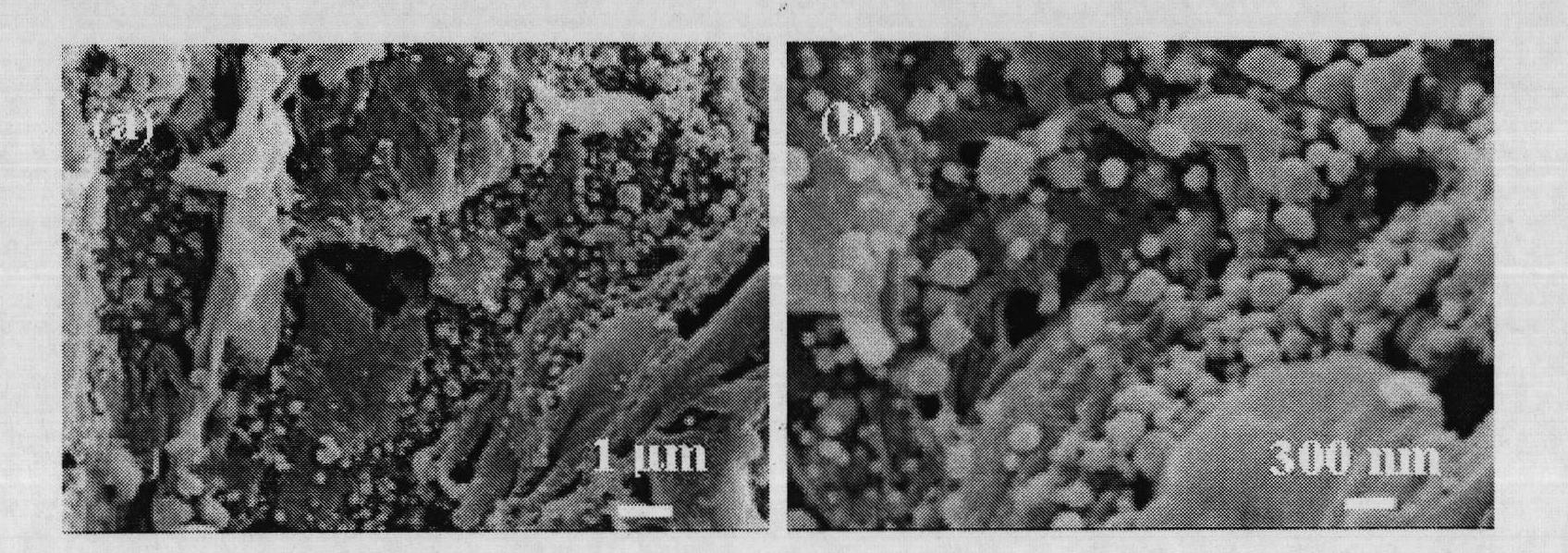

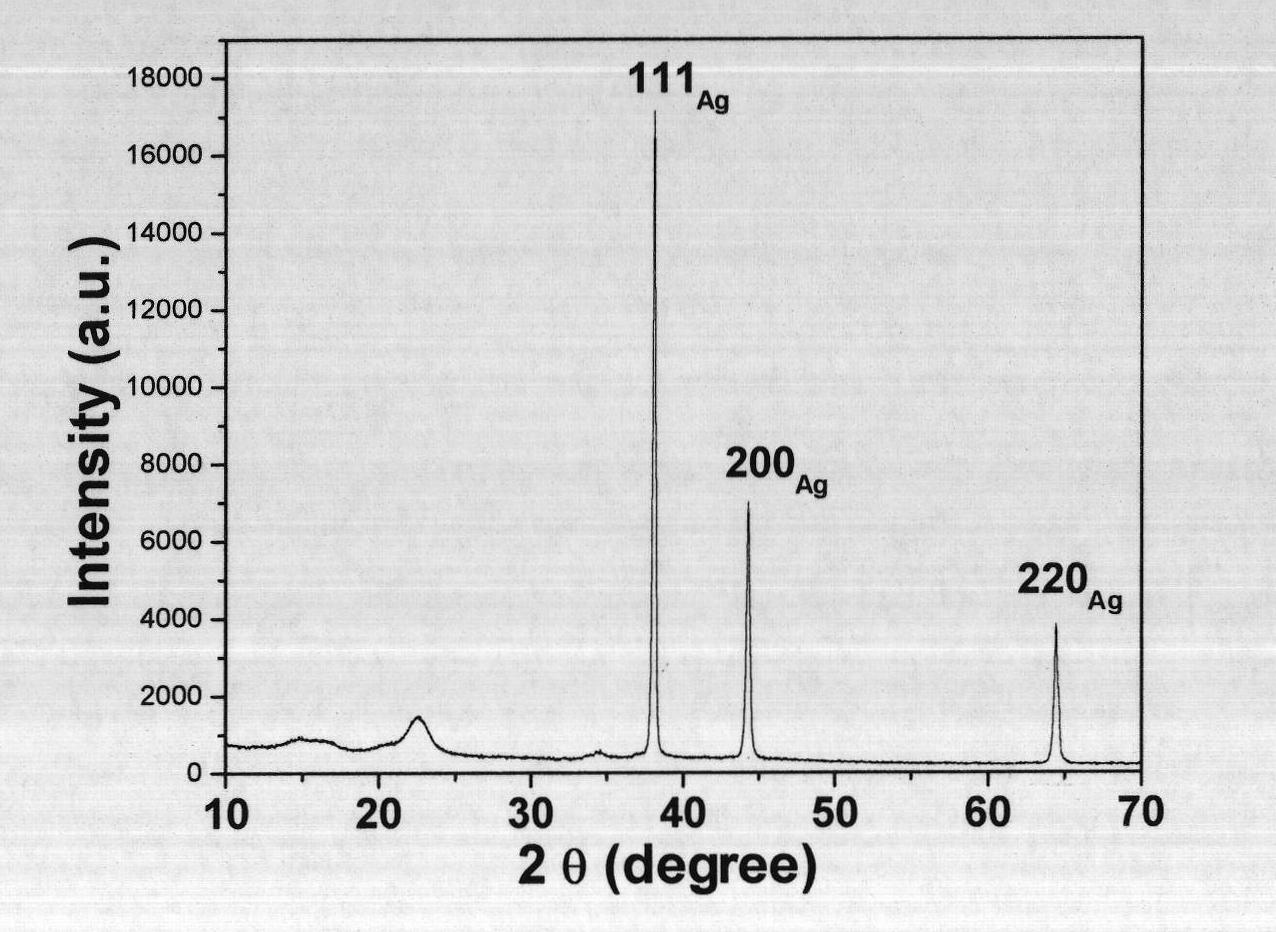

[0075] The morphology of the prepared cellulose / silver nanocomposites was examined by scanning electron microscopy. FIG. 5 is a scanning electron micrograph of the cellulose / silver nanocomposite prepared in this example. Scanning electron micrographs show that the silver nanoparticles prepared in this example are dispersed on the microcrystalline cellulose substrate. The particle size of the elemental nano silver particles of the cellulose / silver nanocomposite material is 450-500nm, and the content of the nano silver particles in the composite material is 37.7%.

Embodiment 3

[0077] In addition to adding 3.705g LiCl to 40mL N,N-dimethylacetamide in the process of preparing the microcrystalline cellulose solution, forming a LiCl / N,N-dimethylacetamide solution, wherein the mass percent content of LiCl is 9% 3.384g microcrystalline cellulose is dissolved in LiCl / N, and microcrystalline cellulose solution is made in N-dimethylacetamide solution;

[0078] The amount of ascorbic acid used in the preparation of cellulose / silver nanocomposites was 1.762g; the microwave radiation treatment temperature was 180°C, and the treatment time was 5min; the absolute pressure of vacuum drying was 0.01MPa, and the vacuum drying temperature was 40°C. The moisture content of plain / silver nanocomposite material is 1.8%, and all the other are identical with embodiment 1.

[0079] The morphology of the prepared cellulose / silver nanocomposites was examined by scanning electron microscopy. FIG. 6 is a scanning electron micrograph of the cellulose / silver nanocomposite prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com