Method for processing flexible metal-plastic thrust bearing bush of main transmission box for milling equipment with laser

An elastic metal and laser treatment technology, which is applied in the field of metallurgy, can solve the problems of accelerated wear of the plastic layer on the surface of the bearing bush, and achieve the effects of increasing adhesion and oil storage performance, enhancing dry friction and lubrication performance, and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

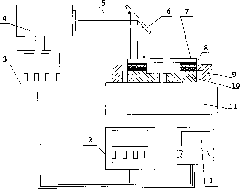

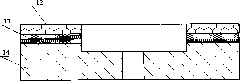

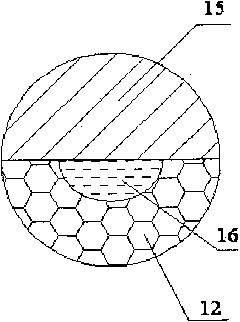

[0018] Such as figure 1 The laser shock treatment device for elastic metal-plastic thrust bearing bush of the present invention is mainly composed of an optical system, a fixture system and a control system, wherein the optical system includes a laser 4 and a reflector 6, and the fixture system includes a fixture 9, a coating 8, a constraining layer 7 and the rotary table 11, the control system includes a computer 1, a table control device 2, and a laser control device 3. The computer 1 is connected with the workbench control device 2 and the laser control device 3. The laser beam 5 emitted by the laser 4 is reflected by the mirror 6 and irradiates the surface of the bearing bush 10. The bearing bush 10 is installed in the fixture 9 connected with the workbench 11. The bearing bush 11 Coating the coating 8 on the surface, and covering the constraining layer 7 on the coating 8 .

[0019] When performing laser shock treatment, the computer 1 issues an instruction, and the lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com