Process for effectively treating organophosphorus pesticide wastewater

A technology for pesticide wastewater and wastewater, which is applied in water/sewage treatment, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of complex treatment process, refractory degradation, and poor biodegradability, etc., and achieves simple pharmaceutical methods , Biodegradability improvement, toxicity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

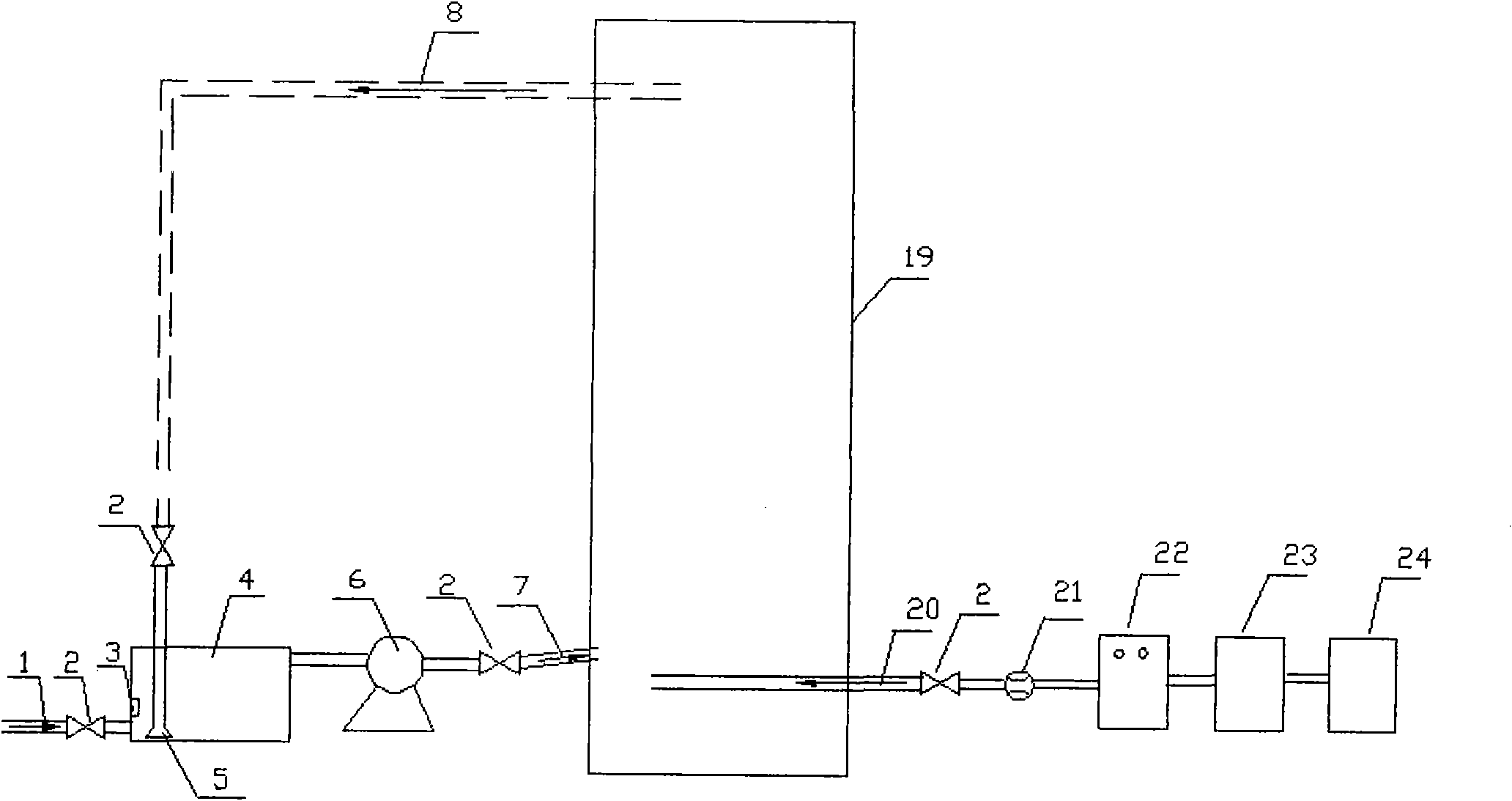

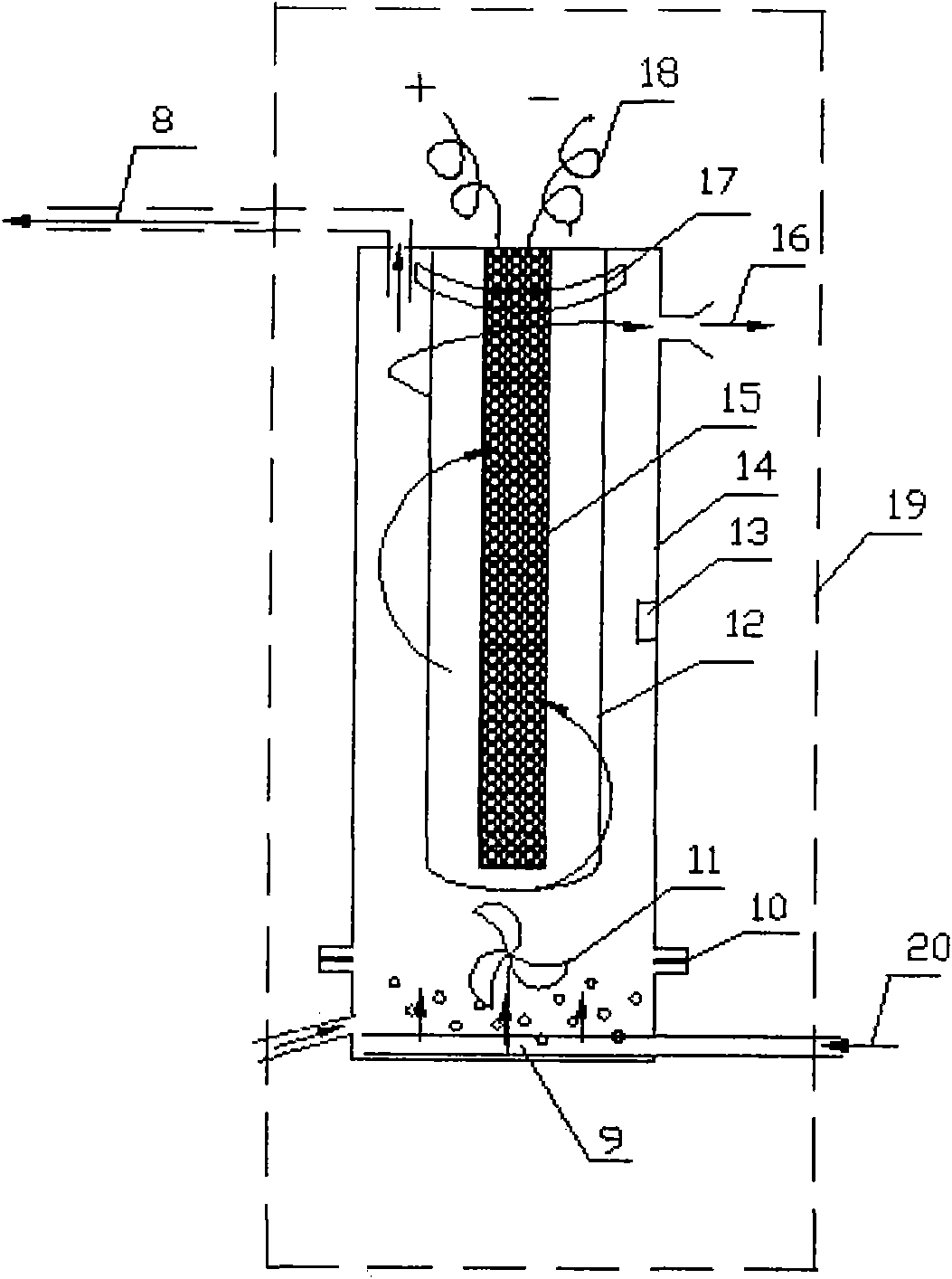

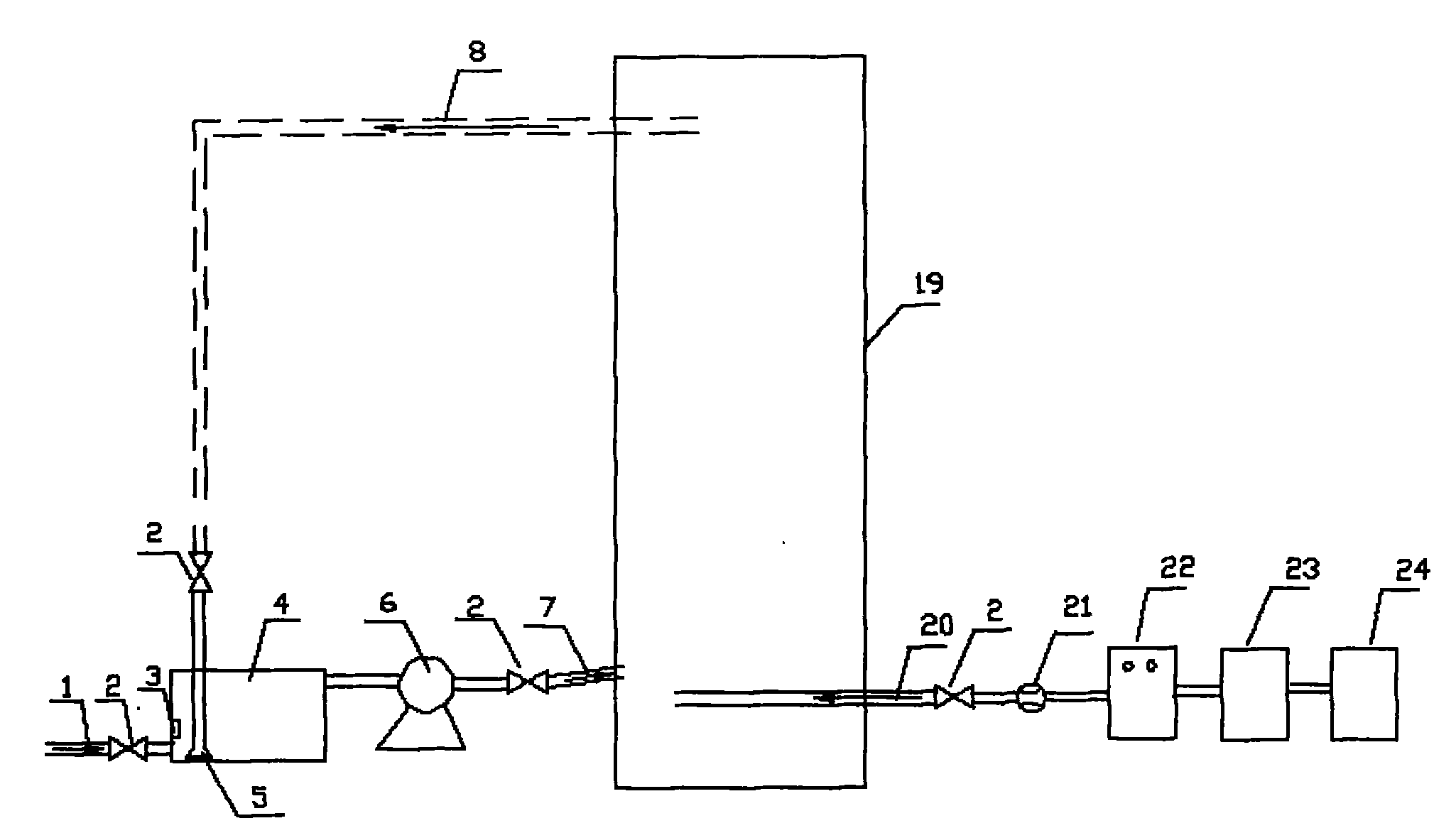

Method used

Image

Examples

Embodiment 1

[0021] The dichlorvos pesticide technical product produced by a pesticide factory was used to prepare a 100mg / L dichlorvos pesticide solution as the wastewater to be treated. Utilize process of the present invention to process dichlorvos pesticide wastewater, concrete steps are as follows:

[0022] Dosing potassium permanganate concentration of 30mg / L in the mixed contact reaction chamber of potassium permanganate and ozone, the unique red color of potassium permanganate disappears after 15 minutes; the ozone tail gas of the subsequent ozone / ultraviolet light joint treatment reaction chamber is introduced Potassium permanganate and ozone are mixed in contact with the reaction chamber; ozone gas is continuously filled into the reaction chamber for combined ozone / ultraviolet light treatment, the hydraulic retention time is 30 minutes, and the ozone concentration in the solution phase is maintained at 5-8 mg / L.

[0023] The design parameters of the reaction chamber for combined o...

Embodiment 2

[0028] The dichlorvos pesticide technical product produced by a pesticide factory was used to prepare a 200mg / L dichlorvos pesticide solution as the wastewater to be treated. Utilize process of the present invention to process dichlorvos pesticide wastewater, concrete steps are as follows:

[0029] Dosing potassium permanganate concentration of 50mg / L in the mixed contact reaction chamber of potassium permanganate and ozone, the unique red color of potassium permanganate disappears after 20 minutes; the ozone tail gas of the subsequent ozone / ultraviolet light joint treatment reaction chamber is introduced Potassium permanganate and ozone are mixed in contact with the reaction chamber; ozone gas is continuously filled into the reaction chamber for combined ozone / ultraviolet light treatment, the hydraulic retention time is 30 minutes, and the ozone concentration in the solution phase is maintained at 5-8 mg / L.

[0030] The design parameters of the reaction chamber for combined o...

Embodiment 3

[0036] Using the dimethoate pesticide technical product produced by a pesticide factory, it is configured into a 200mg / L dimethoate pesticide solution as the wastewater to be treated. Utilize process of the present invention to process dimethoate pesticide wastewater, concrete steps are as follows:

[0037] Dosing potassium permanganate concentration of 50mg / L in the mixed contact reaction chamber of potassium permanganate and ozone, the unique red color of potassium permanganate disappears after 30 minutes; the ozone tail gas of the subsequent ozone / ultraviolet light joint treatment reaction chamber is introduced Potassium permanganate and ozone are mixed in contact with the reaction chamber; ozone gas is continuously filled into the reaction chamber for combined ozone / ultraviolet light treatment, the hydraulic retention time is 30 minutes, and the ozone concentration in the solution phase is maintained at 5-8 mg / L.

[0038] The design parameters of the reaction chamber for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com