Energy-storing device with low internal resistance and production method thereof

A technology of low internal resistance and devices, which is applied in the field of low internal resistance energy storage devices and its manufacturing, can solve the problems of high manufacturing precision of circlips, many times of welding, poor contact, etc., and achieve volumetric power density and volumetric energy density. High, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

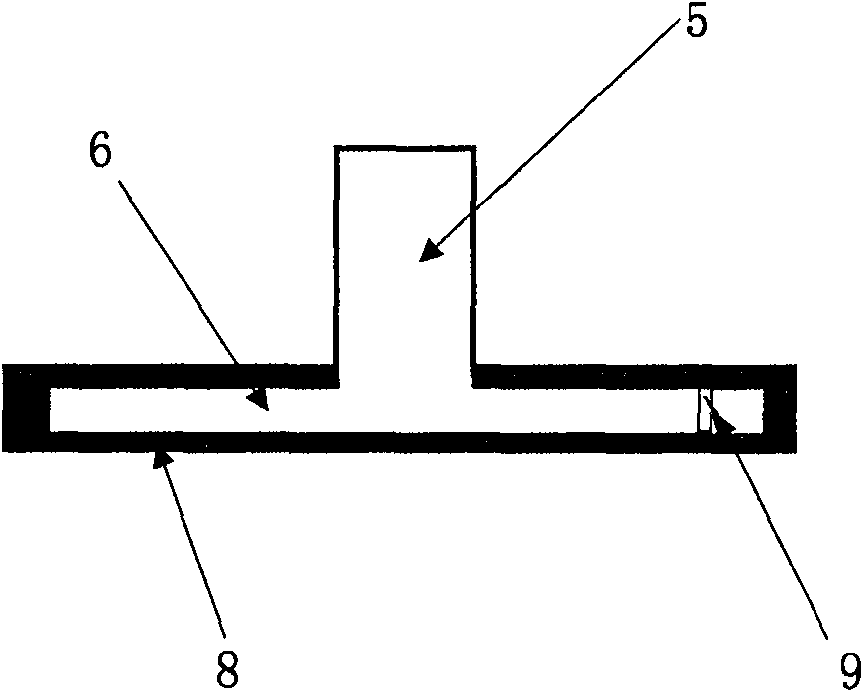

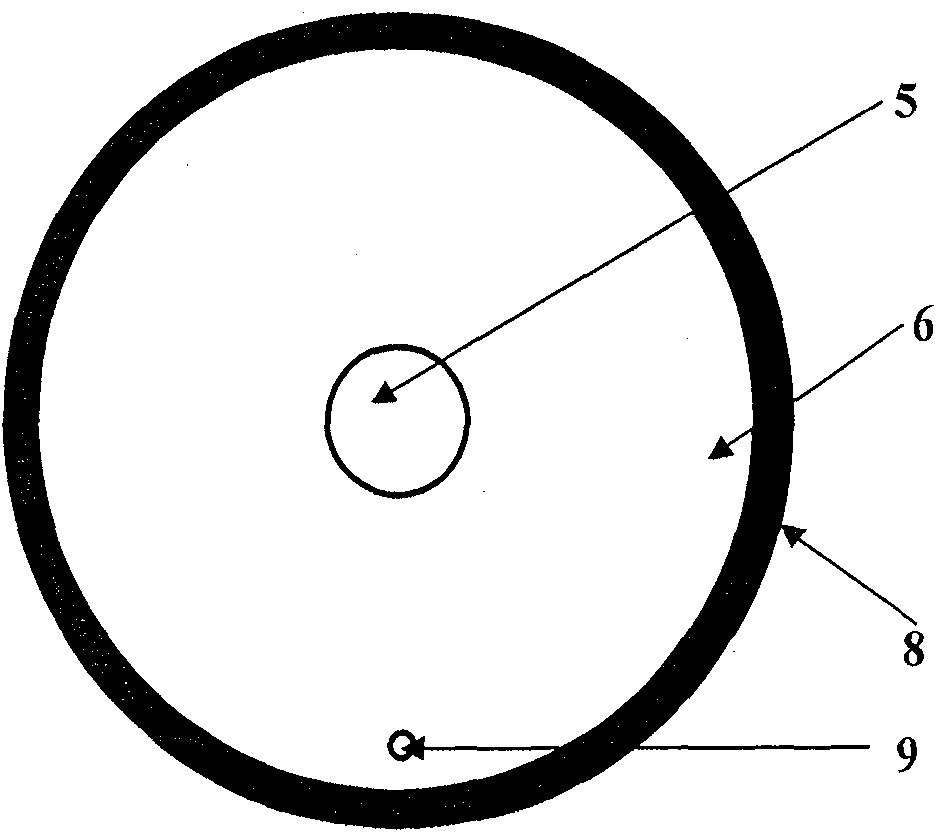

Method used

Image

Examples

Embodiment 1

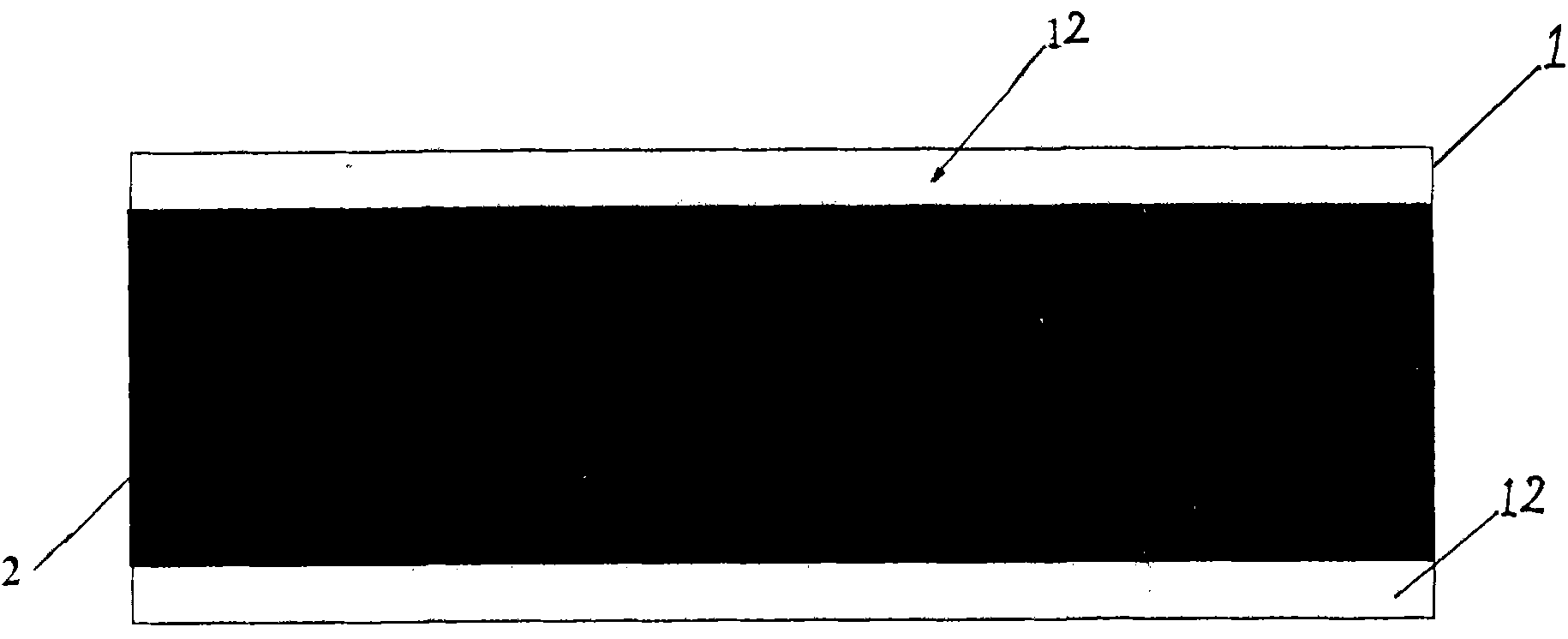

[0029] 1. Positive electrode slurry preparation (by weight): Lithium manganese oxide 95% for commercialized lithium ion batteries, conductive carbon black 2%, commercial lithium ion battery binder L135 (3%) and the total amount of the above solid sample 5 times the total amount of water was mixed in a vacuum planetary mixer for 8 hours to form a uniform slurry.

[0030] 2. Preparation of negative electrode slurry (by weight): 91% of artificial graphite for commercial lithium-ion batteries, 2% of conductive carbon black, binder SBR (5%), CMC (2%) and the total amount of the above solid sample 3.8 times the total amount of deionized water was mixed in a vacuum planetary mixer for 8 hours to form a uniform slurry.

[0031] ③ Slurry coating: Use a coating machine to evenly coat the above prepared positive electrode slurry on the aluminum foil current collector, and coat the negative electrode slurry on the copper foil current collector, and leave 10mm gaps on both sides of the cur...

Embodiment 2

[0053] 1. Positive electrode slurry preparation (by weight): 85% of activated carbon for commercialized organic supercapacitors, 8% of conductive carbon black, commercial lithium-ion battery binder L133 (7%) and the total amount are the total amount of the above solid samples 5 times water, mixed in a vacuum planetary mixer for 8 hours to form a uniform slurry.

[0054] ② Negative electrode slurry preparation: same as Step ① of Example 2.

[0055] ③ Slurry coating: same as the ③ step of embodiment 1.

[0056] ④ Pole sheet rolling: same as step ④ of Example 1.

[0057] 5. pole piece cutting: same as the 5th step of embodiment 1.

[0058] 6. Winding core pack, shell: the same as the 6th step of embodiment 1.

[0059] 7. Welding: same as the 7th step of embodiment 1.

[0060] 8. drying: same as the 8th step of embodiment 1.

[0061] ⑨ Electrolyte injection: Under vacuum, inject the organic supercapacitor commercial electrolyte (1M Et4NBF4 solvent is acetonitrile) into the dr...

Embodiment 3

[0077] ① Positive electrode slurry preparation (by weight): 85% lithium ferrous phosphate for commercial lithium-ion batteries, 7.5% activated carbon, 0.5% conductive carbon black, binder SBR (5%), CMC (2%) And the deionized water whose total amount is 3.8 times of the total amount of the above-mentioned solid sample was mixed in a vacuum planetary mixer for 8 hours to form a uniform slurry.

[0078] ② Negative electrode slurry preparation (by weight): 85% of mesocarbon microspheres for commercial lithium-ion batteries, 10% of conductive carbon black, 0.5% of commercial organic supercapacitor activated carbon, commercial lithium-ion battery binder L135 ( 4.5%) and a total amount of water that is 5 times the total amount of the above-mentioned solid samples were mixed in a vacuum planetary mixer for 8 hours to form a uniform slurry.

[0079] ③ Slurry coating: same as the ③ step of embodiment 1.

[0080] ④ Pole sheet rolling: same as step ④ of Example 1.

[0081] 5. pole piece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Dc internal resistance | aaaaa | aaaaa |

| Dc internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com