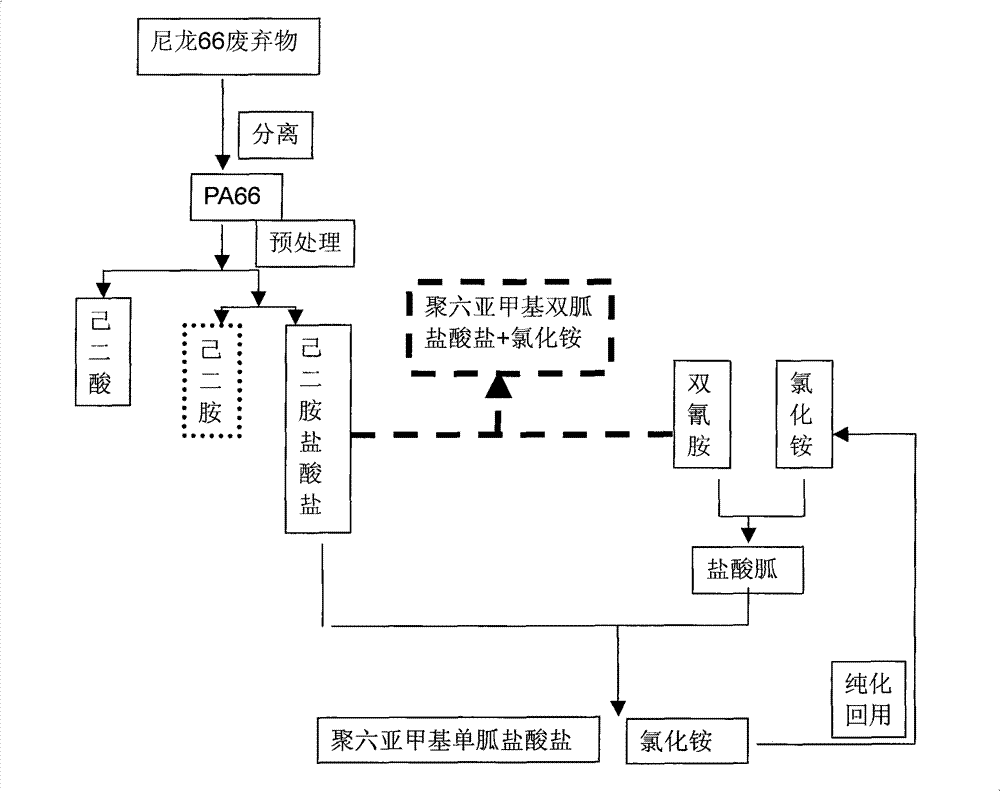

Method for producing adipic acid, hexamethylenediamine hydrochloride and polyhexamethylene (di)guanidine chloride from nylon-66 through depolymerization

A technology of hexamethylene diamine hydrochloride and polyhexamethylene monoguanidine, which is applied in the field of industrial production of polyhexamethylene monoguanidine hydrochloride, can solve the problems of difficult separation, poor production efficiency, and art in other documents or patents None of the issues have been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

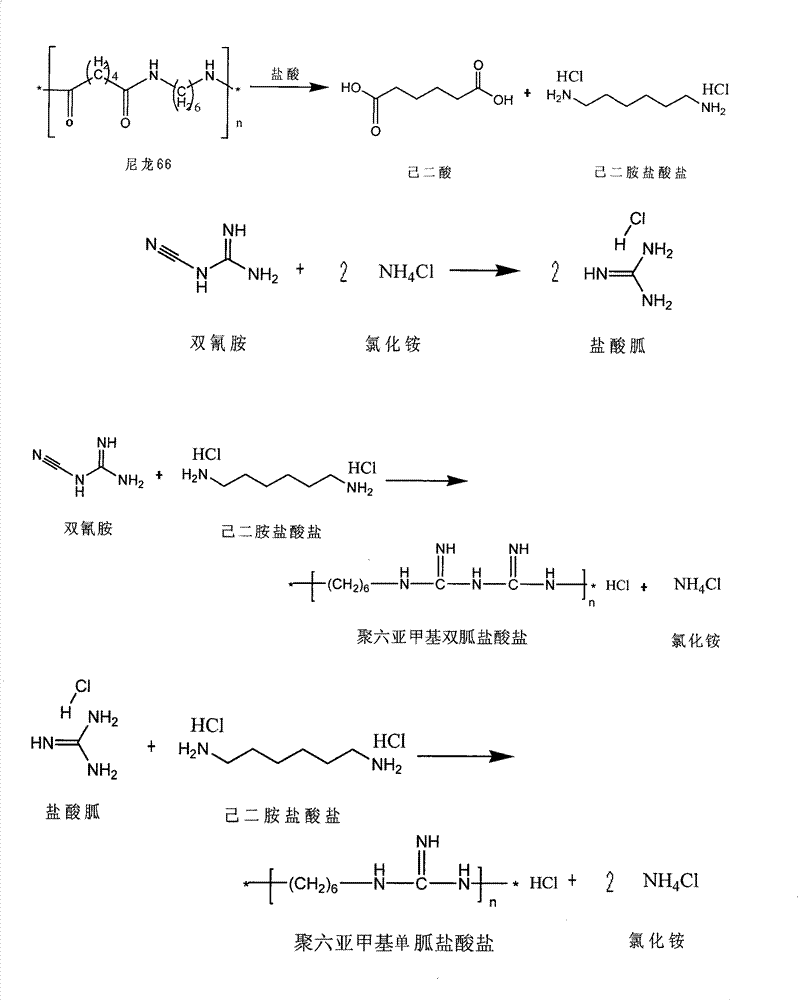

[0027] (1) Depolymerization workshop section: add 30% industrial by-product hydrochloric acid of 1500Kg in the reaction kettle that reflux condenser and hydrochloric acid gas absorption device are housed on the top, add 500Kg water, heat, add waste nylon-66 fragment 1000Kg while stirring, Control the reaction temperature at 100-110° C., normal pressure, and time for 8 hours, and the reaction conversion rate reaches more than 90%, and the acid hydrolysis solution is obtained. The acid solution is filtered through a coarse filter and pressed into the crystallization tank, and the speed of cooling and crystallization is accelerated through top pumping and decompression. Circulating cooling water until the temperature of the crystallization tank drops to 30-40°C. After the crystallization is completed, a box-type filter press is used to separate the crude adipic acid crystals and the crude hexamethylenediamine hydrochloride solution.

[0028](2) Adipic acid refining section: heat...

Embodiment 2

[0032] The depolymerization section (1), adipic acid refining section (2) and hexamethylenediamine hydrochloride refining section (3) are the same as in Example 1.

[0033] (4) In the preparation section of polyhexamethylene mono(bi)guanidine hydrochloride, put dicyandiamide and ammonium chloride powder with a molar ratio of 1:2 into the reactor, under nitrogen protection, stir for 25min, and heat up to 180°C , stirred and reacted for 2h, slowly added the hexamethylenediamine hydrochloride powder obtained in the refining section (3) of hexamethylenediamine hydrochloride, and continued to react for 5h to obtain a mixture of polyhexamethylene monoguanidine hydrochloride and ammonium chloride, While hot, use nitrogen gas to slowly press the molten reaction liquid into a separation tank filled with industrial ethanol, stir well and then filter, and distill the polyhexamethylene monoguanidine hydrochloride ethanol filtrate to remove ethanol under reduced pressure to obtain light yel...

Embodiment 3

[0035] The depolymerization section (1), adipic acid refining section (2), hexamethylenediamine sulfate refining section (3) and polyhexamethylene mono(bi)guanidine sulfate preparation section (4) are the same as in Example 2.

[0036] Add 300Kg of hot water (80±5°C) to the crude ammonium chloride white powder obtained after the above filtration, stir, dissolve and filter, evaporate and concentrate under reduced pressure until crystals are precipitated, cool, filter, and vacuum dry to obtain 150Kg of refined sulfuric acid Ammonium solid, the yield is over 86%. According to the reaction equivalence ratio, fresh ammonium chloride is properly supplemented and recycled to the polyhexamethylene mono(bi)guanidine hydrochloride preparation section (4).

[0037] The general molar ratio herein refers to allowing the molar ratio to fluctuate by 10% on the basis of equivalent reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com