Low cost environmental protection ultra-tough rigid polyvinyl chloride nano compound capable of injection molding and preparation method

A technology of rigid polyvinyl chloride and nanocomposites, which is applied in the field of low-cost, environmentally friendly, injection-molded ultra-tough rigid polyvinyl chloride nanocomposites and its preparation, and can solve problems such as poor low-temperature toughness, low impact strength, and temperature influence , to achieve the effect of high impact resistance, good flame retardancy and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

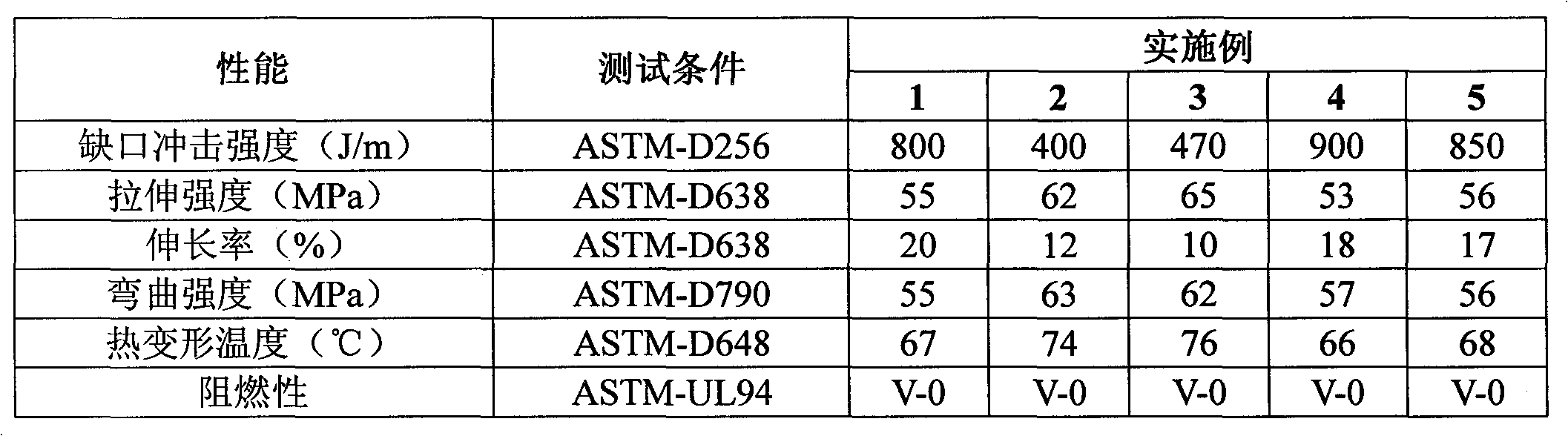

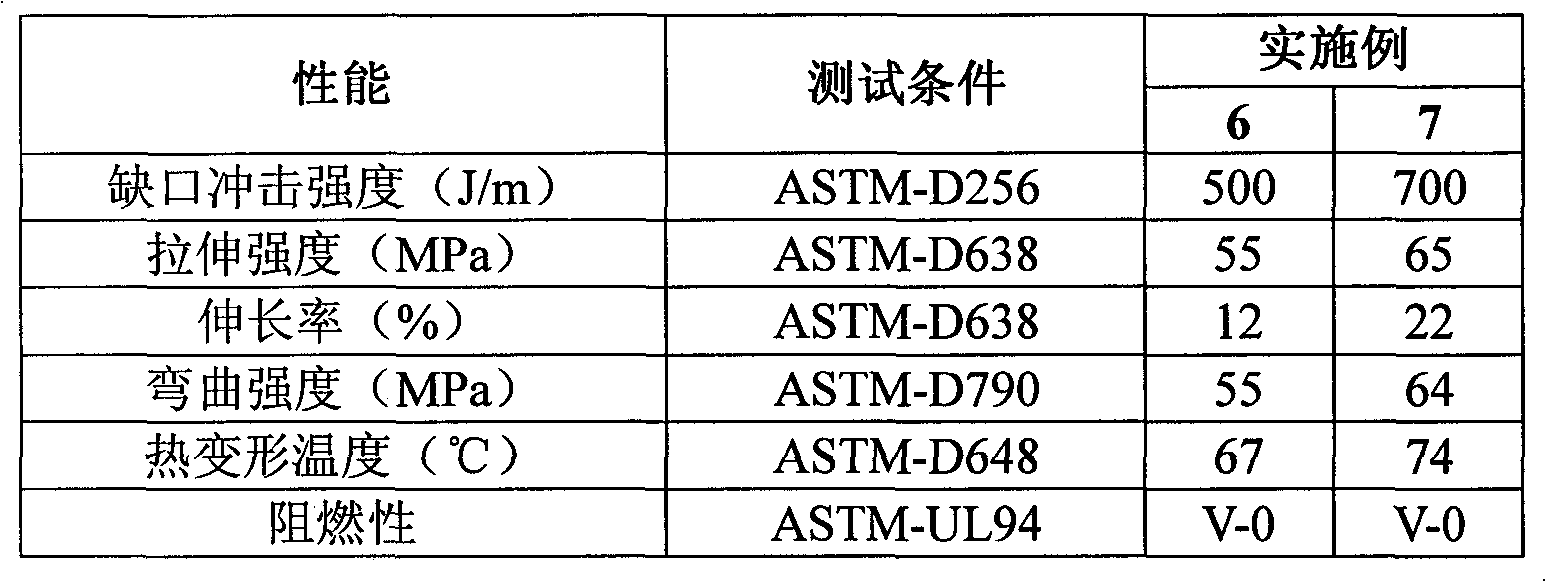

Examples

Embodiment 1

[0018] Add 30 parts by weight of stearic acid-treated nano-calcium carbonate and 20 parts by weight of acrylonitrile-butadiene-styrene terpolymer of HR181 into a high-speed mixer for mixing, and cool the discharge to obtain nano-calcium carbonate / acrylonitrile - Butadiene-styrene terpolymer compound; 100 parts by weight of polyvinyl chloride of S700, 2 parts by weight of lanthanum stearate and lanthanum tin with organic tin methyl mercaptide in a weight ratio of 6:4 Add the stabilizer to the high-speed mixer, mix to 60°C, add 3 parts by weight of acrylic resin processing aid, 1 part by weight of monoglyceride stearate in sequence, mix to 80°C, add 0.5 parts by weight of oxidized polyethylene wax, and mix to 90°C, add nano-calcium carbonate / acrylonitrile-butadiene-styrene terpolymer compound, mix to 120°C, discharge and cool to obtain polyvinyl chloride nano-composite; add polyvinyl chloride nano-composite to the cone Shaped twin-screw extruder, the temperature in the first zon...

Embodiment 2

[0020] Add 20 parts by weight of stearic acid-treated nano calcium carbonate and 5 parts by weight of HR150F acrylonitrile-butadiene-styrene terpolymer into a high-speed mixer for mixing, and cool the discharge to obtain nano calcium carbonate / acrylonitrile- Butadiene-styrene terpolymer compound; 100 parts by weight of polyvinyl chloride of brand position S-1000, 2 parts by weight of lanthanum stearate and organic tin methyl mercaptide with a weight ratio of 6:4 lanthanum tin Add the composite stabilizer to a high-speed mixer, mix to 60°C, add 3 parts by weight of acrylic resin processing aid, 2 parts by weight of calcium stearate, and mix to 80°C, add 0.5 parts by weight of paraffin, and mix to 100°C. Add nano-calcium carbonate / acrylonitrile-butadiene-styrene terpolymer compound, mix to 120°C, discharge and cool to obtain polyvinyl chloride nanocomposite; add polyvinyl chloride nanocomposite to conical twin-screw extruder Out of the machine, under the conditions that the temp...

Embodiment 3

[0022] Add 10 parts by weight of coupling agent-treated nano-calcium carbonate and 10 parts by weight of acrylonitrile-butadiene-styrene terpolymer of HR183 into a high-speed mixer for mixing, and cool the discharge to obtain nano-calcium carbonate / acrylonitrile- Butadiene-styrene terpolymer composite; 100 parts by weight of polyvinyl chloride at the brand position SG5, 2 parts by weight of lanthanum stearate and lanthanum tin with methyl mercaptan organotin weight ratio of 6:4 are compounded and stabilized Add the agent into a high-speed mixer, mix to 60°C, add 3 parts by weight of acrylic resin processing aid, 3 parts by weight of stearic acid in sequence, mix to 80°C, add 0.5 parts by weight of paraffin, mix to 100°C, add nanocarbonic acid Calcium / acrylonitrile-butadiene-styrene terpolymer compound, mixed to 120 ° C and cooled to obtain a polyvinyl chloride nanocomposite; adding the polyvinyl chloride nanocomposite to a conical twin-screw extruder, Melting and extruding und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com