Silicon dioxide optical waveguide device based on B-Ge-codoped upper cladding and preparation method thereof

A technology of silicon dioxide and optical waveguide, which is applied in the direction of light guide, optical components, optics, etc., can solve the problems that phosphorus is easy to be affected by moisture, increase the process risk and product instability, and achieve the elimination of voids, reduce process cost and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

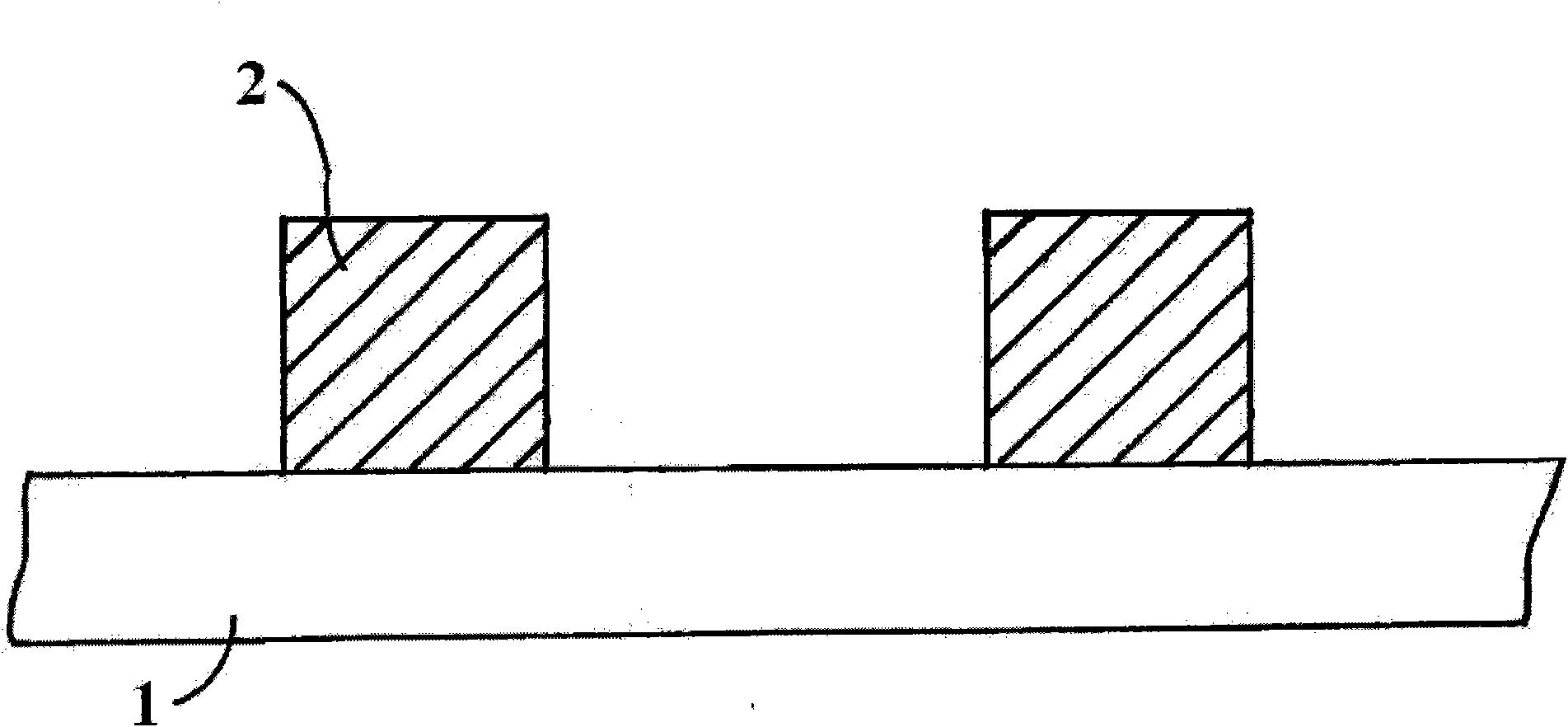

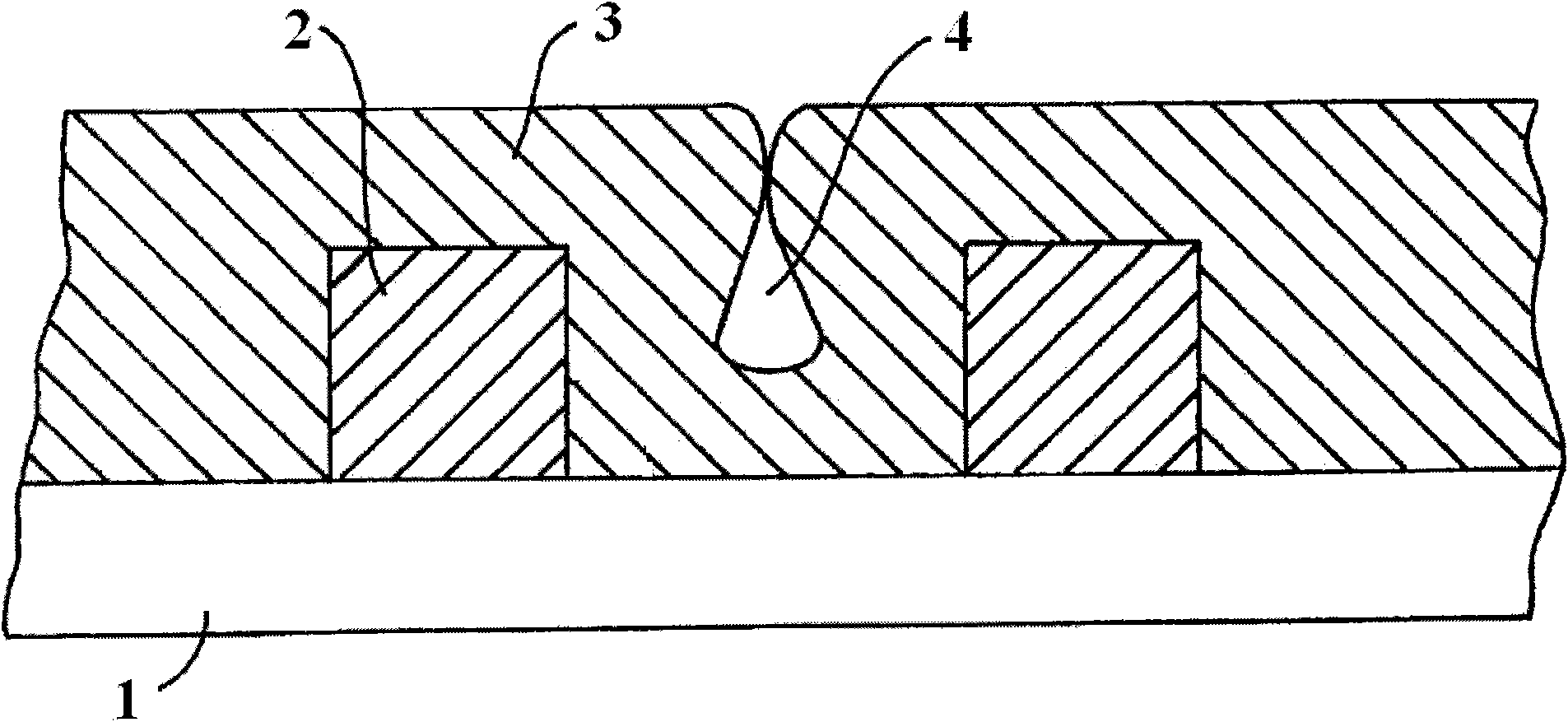

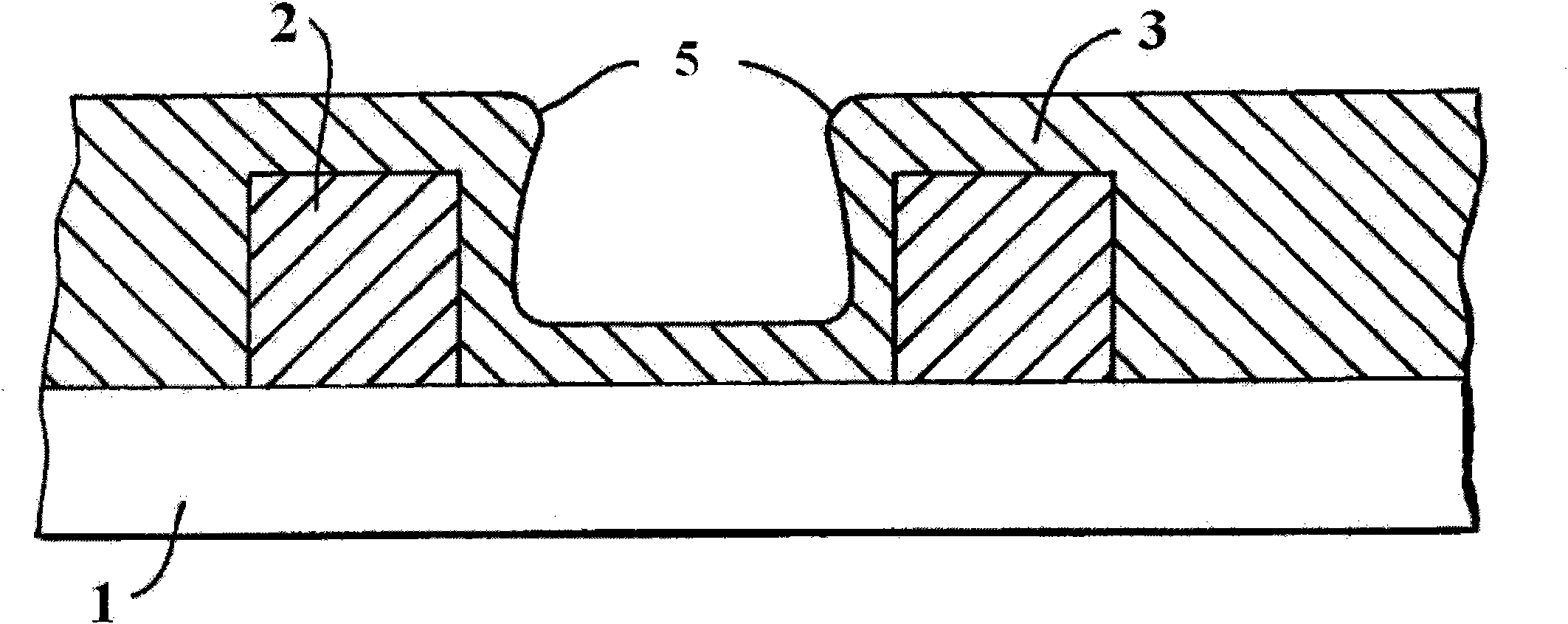

[0045] Such as Figure 5 As shown, in the present invention, a silicon dioxide lower cladding layer 1 is deposited on a substrate, and a germanium-doped silicon dioxide film is deposited on the upper surface of the lower cladding layer 1, and then a waveguide core layer 2 with a square section is formed by photolithography and etching processes. ; Deposit a layer of silicon dioxide upper cladding layer 3 doped with boron and germanium on top of the silicon dioxide lower cladding layer 1 and the waveguide core layer 2, and there is no gap between the upper cladding layer 3 and the core waveguide 2 structure .

[0046] The deposited silicon dioxide upper cladding layer 3 doped with boron and germanium has the same refractive index as the silicon dioxide lower cladding layer 1, and the melting point and refractive index of the silicon dioxide upper cladding layer 3 are lower than the waveguide core Layer 2.

[0047] The present invention describes a silicon dioxide optical waveguide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com