Clarifying chamber-free continuous extracting device of large-phase ratio easy emulsifying system and operating method

A technology of extraction device and clarification chamber, which is applied in the field of continuous extraction device without clarification chamber, can solve the problems of small volume of liquid to be dispersed, difficult to fully disperse, etc., and achieves the effect of simple structure and easy enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

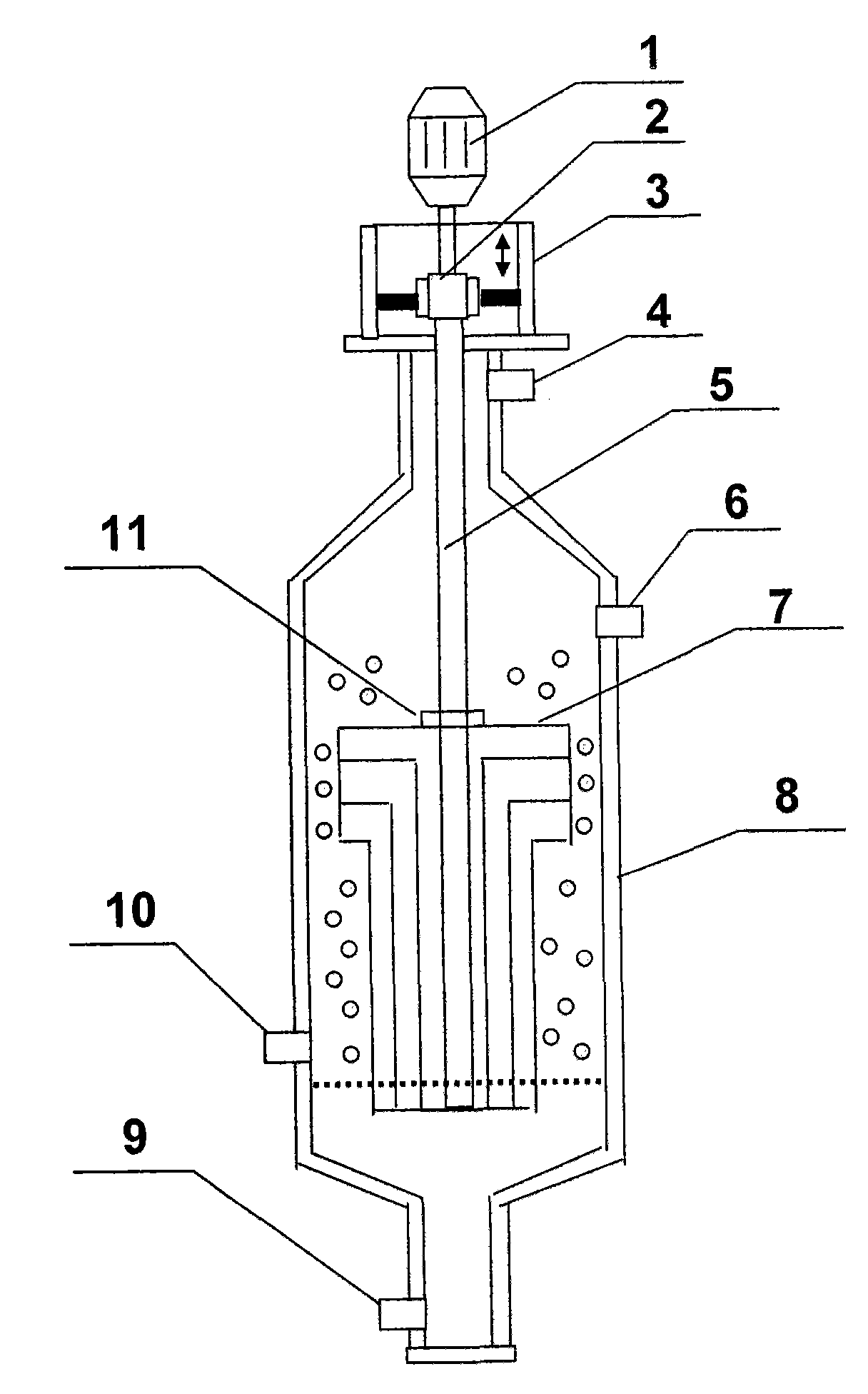

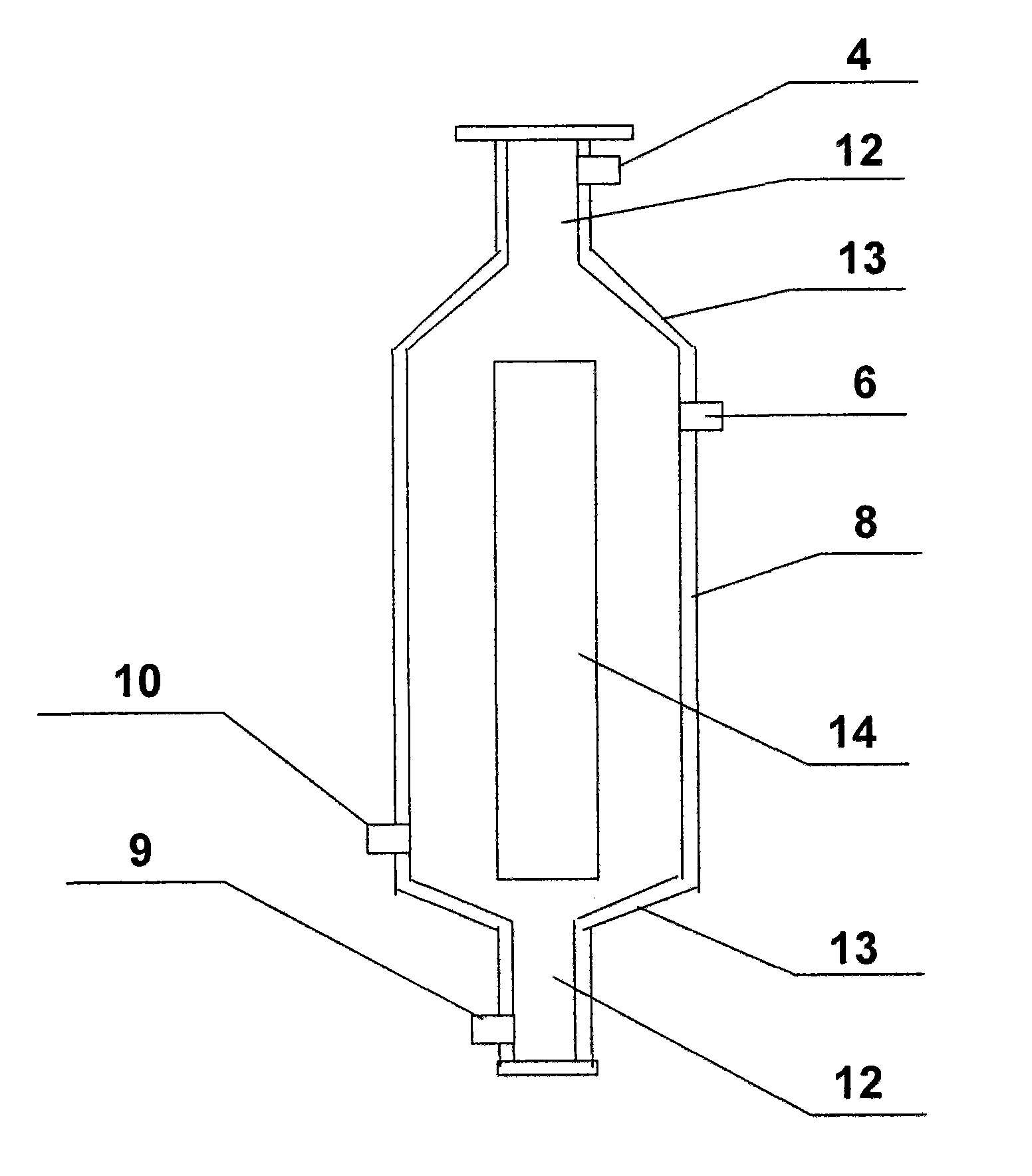

[0038] The organic phase is 50mM AOT / petroleum ether (bp.: 90-120°C), the aqueous phase is lysozyme containing 1mg / mL, 0.05M borax-hydrochloric acid (HCl) buffer, potassium chloride salt concentration 0.1M, pH = 9.0. The inner diameter of the tower body cavity is 80mm, the height is 100mm, the height of the cavity at both ends of the tower body is 20mm, the diameter of the enlarged end of the liquid phase disperser is 60mm, the maximum diameter of the concentric cylinder is 40mm, the distance between each cylinder is 4mm, and the total height of the liquid phase disperser is 70mm . The heavy phase water phase is used as the dispersed phase, and the structure of the device is as follows: figure 1 shown. Motor speed 600r / min. A single-stage continuous extraction operation is carried out, and the two-phase flow ratio is controlled so that the volume ratio of the organic phase and the aqueous phase in the tower is 12:1. The concentration of lysozyme in the water phase flowing ...

Embodiment 2

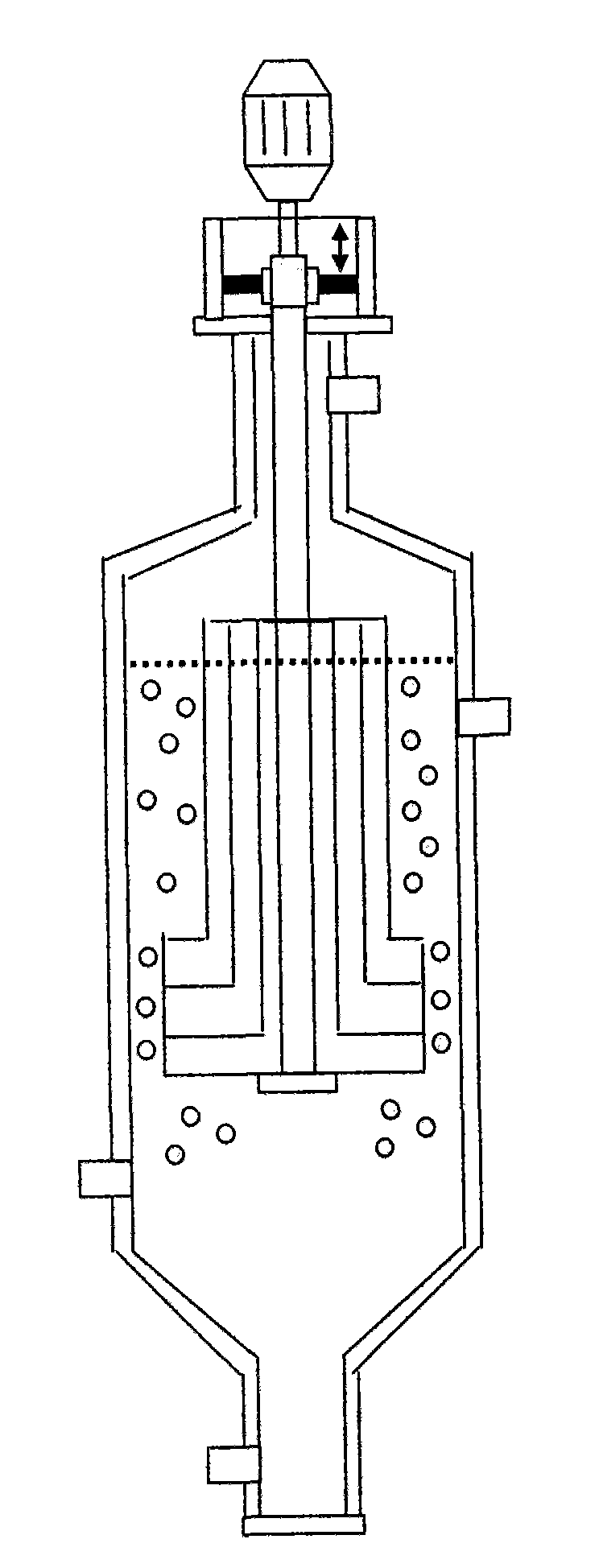

[0040] The organic phase is 5.7wt% tributylphosphine oxide (TBPO) in butyl acetate solution, the aqueous phase is 0.05M penicillin potassium saline solution containing 1 mg / mL whey protein, pH=4.0. The structural parameters of the tower body and the liquid phase disperser are the same as in Example 1. The light organic phase is used as the dispersed phase, and the structure of the device is as follows: figure 2 shown. Motor speed 600r / min. A single-stage continuous extraction operation is carried out, and the two-phase flow ratio is controlled so that the volume ratio of the organic phase and the aqueous phase in the tower is 1:15. Detect the content of penicillin in the water phase flowing out from the heavy phase outlet 9 on the side of the cylindrical cavity below the shrinkage section at the bottom of the tower body, and the extraction rate is 92.5%.

Embodiment 3

[0042] The organic phase and water are the same as Example 1. The structural parameters of the tower body and the liquid phase disperser of the single-stage extraction device are the same as in Example 1. The motor speed of each extraction device is also the same, fixed at 600r / min. The heavy phase water phase is used as the dispersed phase, and the three-stage series continuous extraction operation is carried out. The device structure is as follows: Image 6 shown. The two phases flow countercurrently in the device, and the flow ratio of the two phases is controlled so that the volume ratio of the organic phase and the aqueous phase in each extraction device is 15:1. The concentration of lysozyme in the water phase flowing out from the heavy phase outlet 9 at the bottom of the tower body of the last stage extraction device was detected, and the extraction rate was 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com