Polyaryletherketone resin with high thermal stability and preparation method thereof

A high thermal stability, polyaryl ether ketone technology, applied in the field of polymer materials, can solve the problems of backward thermal stability, inability to get rid of aging, product performance degradation, etc. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The polyaryletherketone resin used is polyetheretherketone (PEEK), and its structural formula is:

[0047]

[0048] Further, the melt index of the polyetheretherketone resin used is 21g / 10min, the amount of resin is 100 parts by weight, the heat stabilizer is phosphite antioxidant S-9228, and the addition amount is 0 parts.

[0049]Specific operation steps: first use a high-speed mixing mixer to mix polyether ether ketone resin and heat stabilizer in proportion; then send the above mixture into a twin-screw extruder through a feeder, fully melt, compound, and then extrude through the head Extrusion, cooling, granulation, and finally form a composite pellet product. The heating temperature of each section of the twin-screw extruder is: 300°C, 350°C, 355°C, 355°C, 355°C, 355°C, 355°C, 345°C; the control screw speed is: 120rpm.

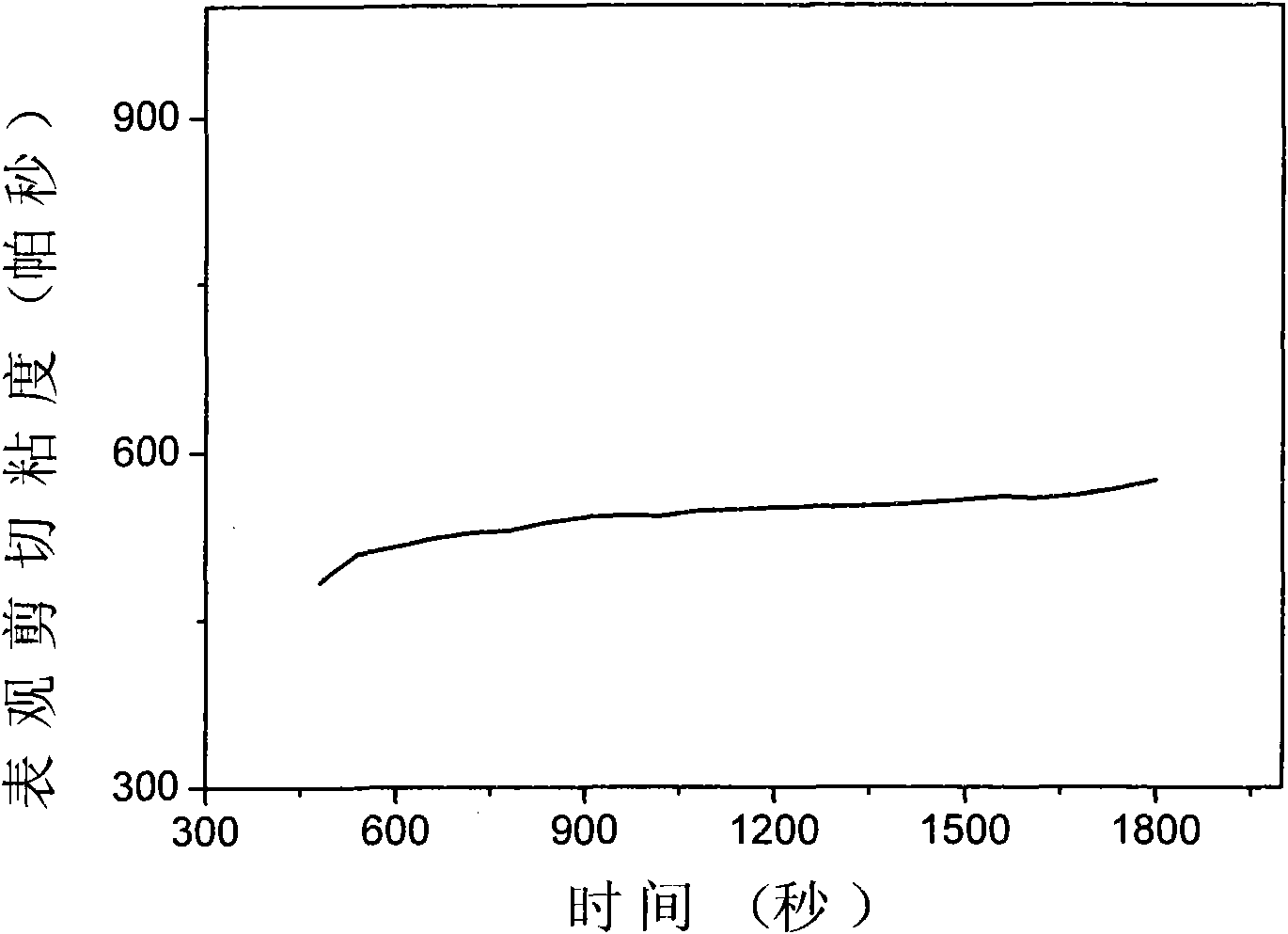

[0050] The prepared composite pellets were injection molded into standard specimens according to the GB / T 1040-1992 standard, and adjusted fo...

Embodiment 2

[0053] As described in Example 1, only the amount of resin added in Example 1 is changed to 99.9 parts, and the amount of heat stabilizer added is 0.1 part. Other operations are the same as in Example 1.

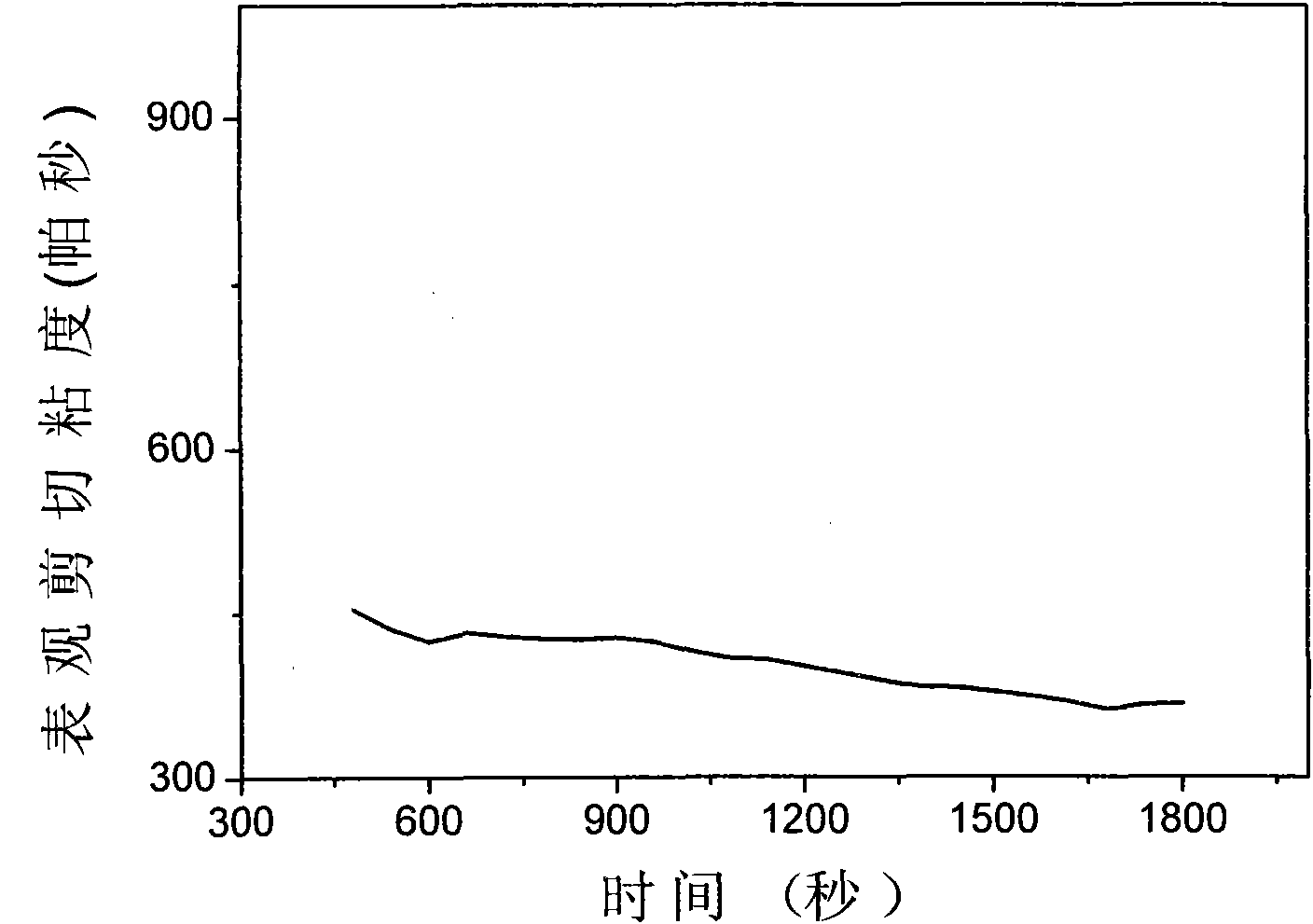

[0054] The test results are: tensile strength 102MPa, elongation at break 53%, flexural strength 171MPa, flexural modulus 3602MPa; 5% thermal weight loss temperature 578°C; apparent viscosity changed from initial 400PaS to 360PaS, as figure 2 shown.

Embodiment 3

[0056] As described in Example 1, just change the amount of resin added in Example 1 to 99 parts, and the amount of heat stabilizer added is 1 part, and other operations are the same as in Example 1.

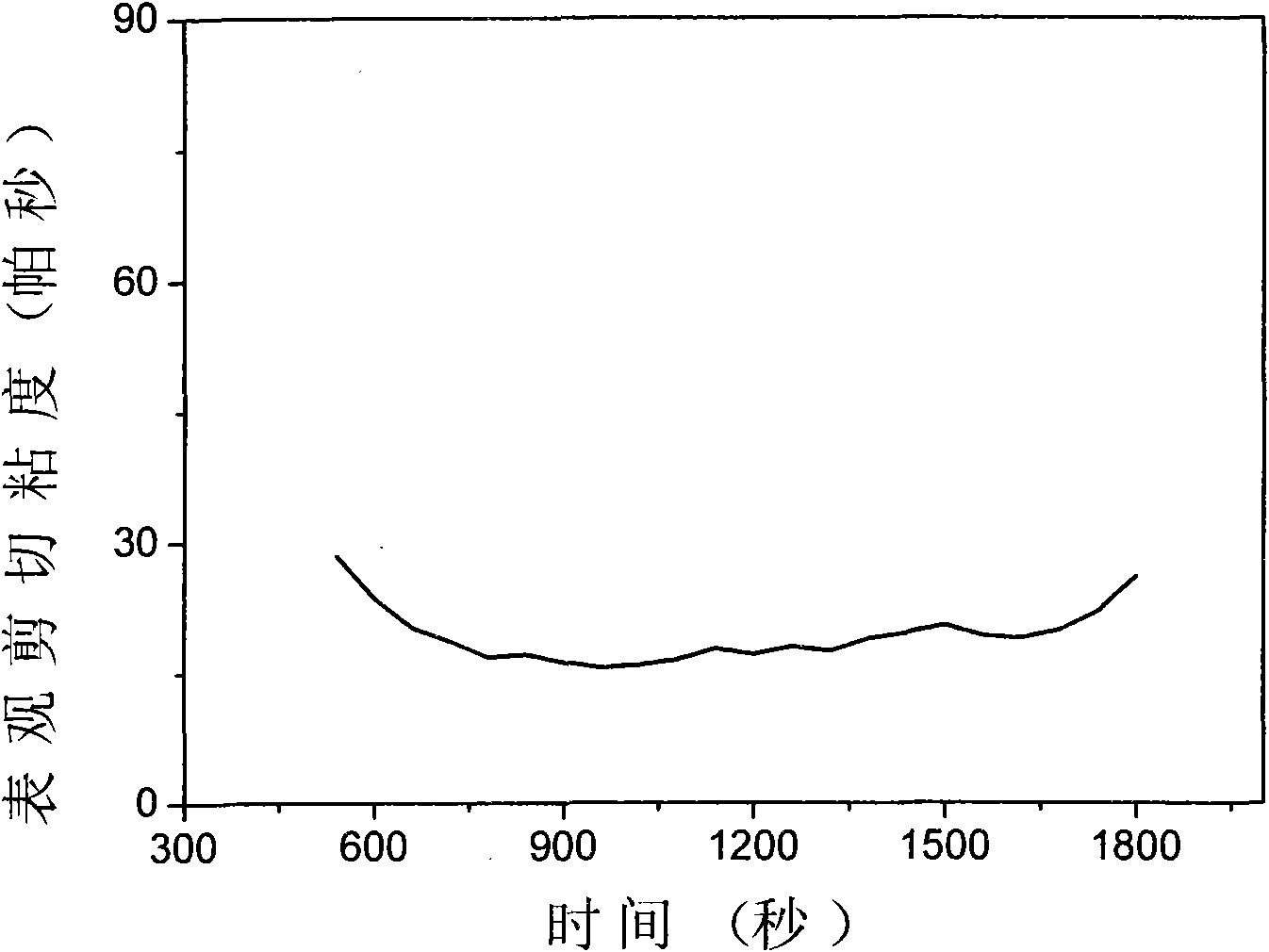

[0057] The test results are: tensile strength 112MPa, elongation at break 34%, flexural strength 118MPa, flexural modulus 4065MPa; 5% thermal weight loss temperature 577 ° C; apparent viscosity from the initial 30Pas to 23Pas, as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com