Single dose immunization against tetanus toxin cation dextran microspheres and preparation method thereof

A technology of tetanus toxoid and dextran, which is applied in the direction of pharmaceutical formulas, medical preparations of non-active ingredients, bacterial antigen components, etc., can solve the problem of low encapsulation volume and encapsulation efficiency, low encapsulation rate, coagulation and problems such as precipitation, to achieve the effect of improving vaccination coverage, realizing full-course immunization, and reducing the number of injections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

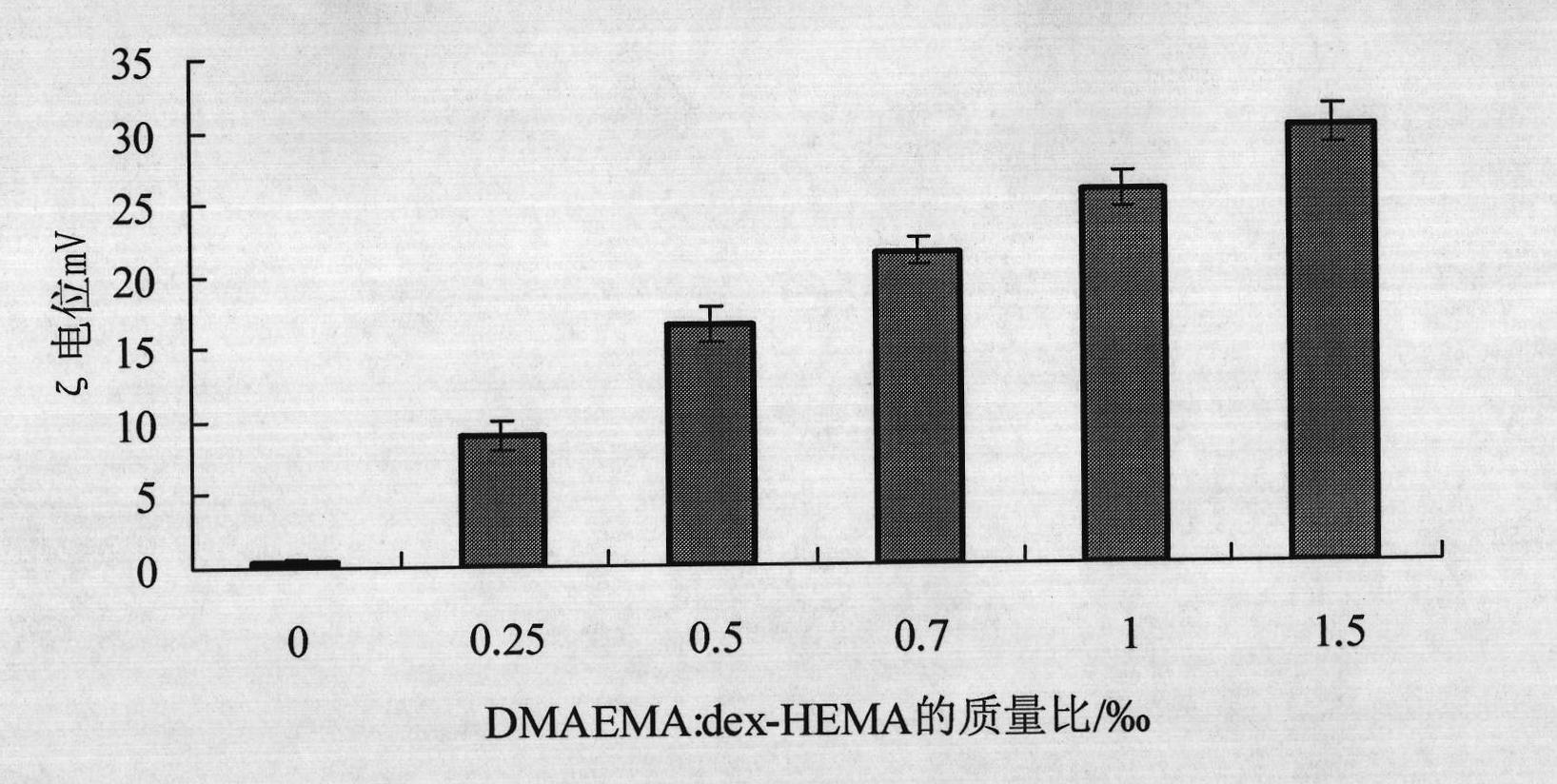

[0037] (1) 71 mg of hydroxyethyl methacrylate dextran (molecular weight 20,000, DS=3) was dissolved in 1.577 g of water, and 35 μl of dimethylaminoethyl methacrylate was added under stirring to obtain hydroxyethyl methacrylate Dextran phase;

[0038] (2) 20,001 g of polyethylene glycol was dissolved in 3.34 ml of water to obtain the polyethylene glycol phase;

[0039] (3) under stirring (1000rpm), the hydroxyethyl methacrylate dextran phase is added to the polyethylene glycol phase;

[0040] (4) Under stirring (500rpm), add 0.1ml tetramethylethylenediamine (20%, V / V, 4M hydrochloric acid to neutralize) and 0.18ml potassium persulfate (50mg / ml) into the upper solution respectively , cross-link for 1h (37 degrees) after stopping stirring;

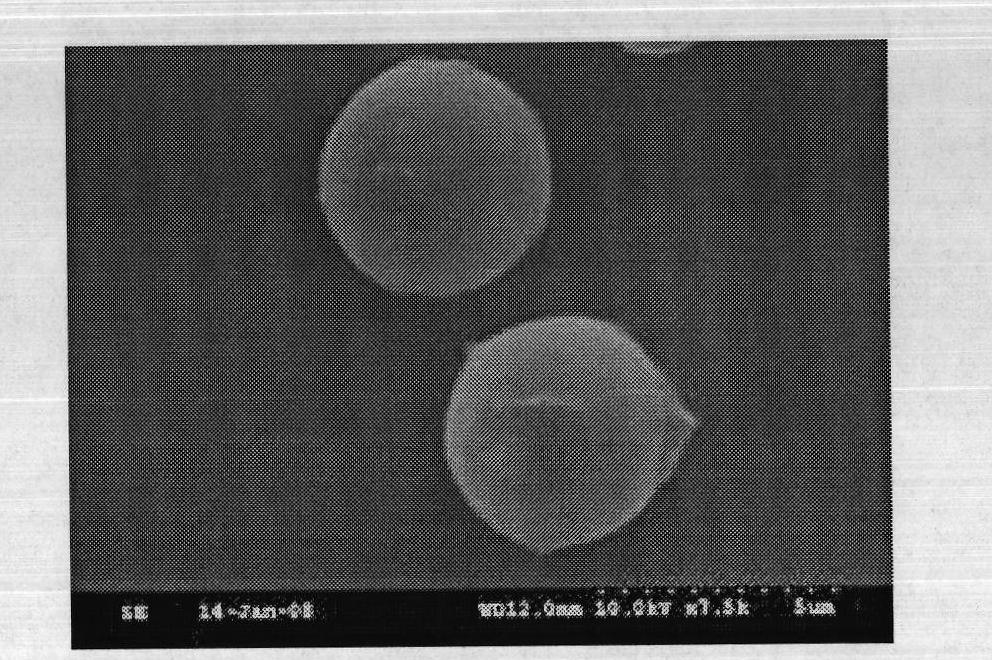

[0041] (5) Wash off the supernatant with water under centrifugation, and freeze-dry to obtain blank microsphere powder.

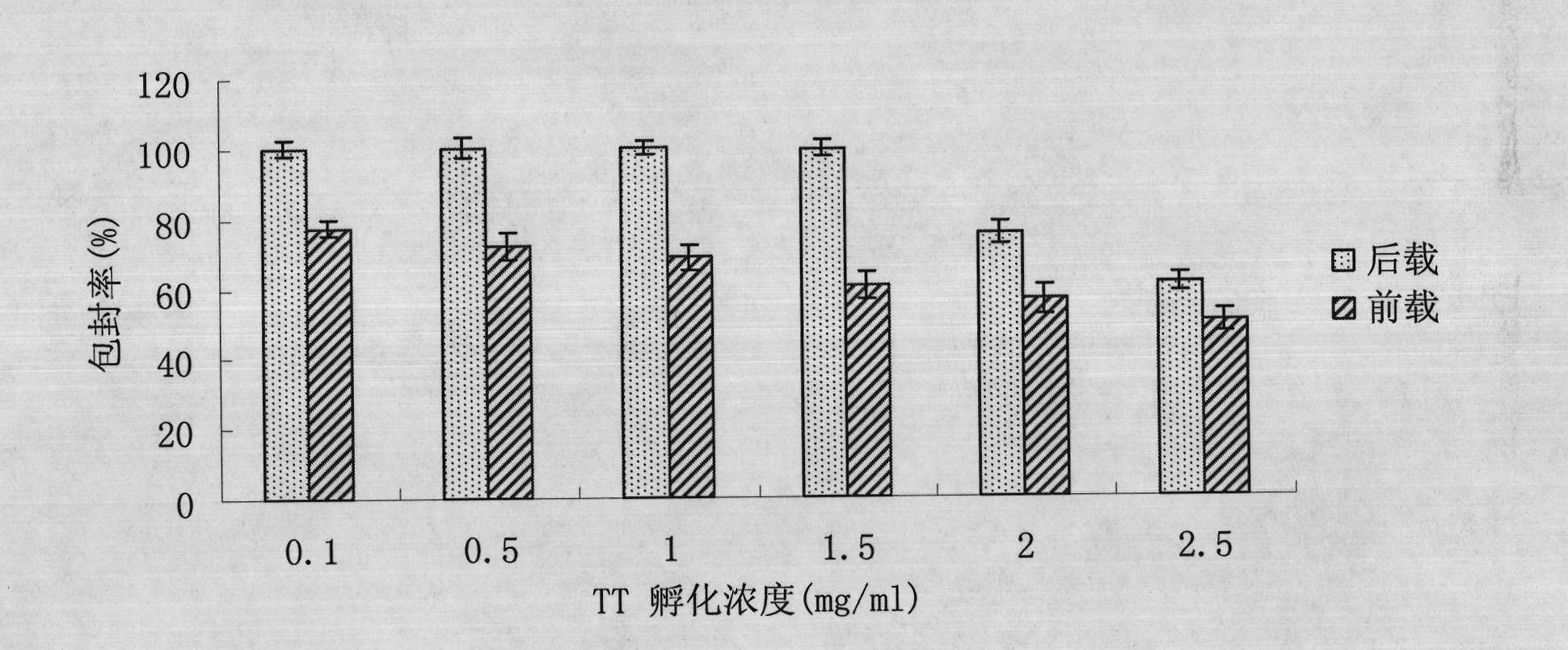

[0042] (6) Weigh 70 mg of blank microsphere powder, add 5 ml of 1 mg / ml tetanus toxoid solution, incubate for 24 hours ...

Embodiment 2

[0045] (1) 71 mg of hydroxyethyl methacrylate dextran (molecular weight 20,000, DS=3) was dissolved in 1.577 g of water, and 35 μl of dimethylaminoethyl methacrylate was added under stirring to form hydroxyethyl methacrylate Dextran phase;

[0046] (2) 20,001 g of polyethylene glycol is dissolved in 5 ml of water to form a polyethylene glycol phase;

[0047] (3) under stirring (2000rpm), the hydroxyethyl methacrylate dextran phase is added to the polyethylene glycol phase;

[0048] (4) Under stirring (500rpm), add 0.1ml tetramethylethylenediamine (20%, V / V, 4M hydrochloric acid to neutralize) and 0.18ml potassium persulfate (50mg / ml) into the upper solution respectively , cross-link for 1h (37 degrees) after stopping stirring;

[0049] (5) Wash off the supernatant with water under centrifugation, and freeze-dry to obtain blank microsphere powder.

[0050] (6) Weigh 70 mg of blank microsphere powder, add 5 ml of 0.5 mg / ml tetanus toxoid solution, incubate for 24 hours (4° C....

Embodiment 3

[0053] (1) 71 mg of hydroxyethyl methacrylate dextran (molecular weight 20,000, DS=3) was dissolved in 1.577 g of water, and 35 μl of dimethylaminoethyl methacrylate was added under stirring to form hydroxyethyl methacrylate Dextran phase;

[0054] (2) Polyethylene glycol 60001g is dissolved in 5ml water to form a polyethylene glycol phase;

[0055] (3) under stirring (500rpm), the hydroxyethyl methacrylate dextran phase is added to the polyethylene glycol phase;

[0056] (4) Under stirring (500rpm), add 0.1ml tetramethylethylenediamine (20%, V / V, 4M hydrochloric acid to neutralize) and 0.18ml potassium persulfate (50mg / ml) into the upper solution respectively , cross-link for 1h (37 degrees) after stopping stirring;

[0057] (5) Wash off the supernatant with water under centrifugation, and freeze-dry to obtain blank microsphere powder.

[0058] (6) Weigh 70 mg of blank microsphere powder, add 5 ml of 1.5 mg / ml tetanus toxoid solution, incubate for 24 hours (4° C.), and cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com