Making method of kaoliang spirit

A production method and technology of sorghum wine, applied in the preparation of alcoholic beverages, etc., can solve the problems of unfavorable industrial utilization value and economic benefits, long-term, usually more than one month, health and safety concerns, etc., to improve the utilization rate of farmland and the economy. Profitable, easy to obtain, and the effect of reducing feed costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

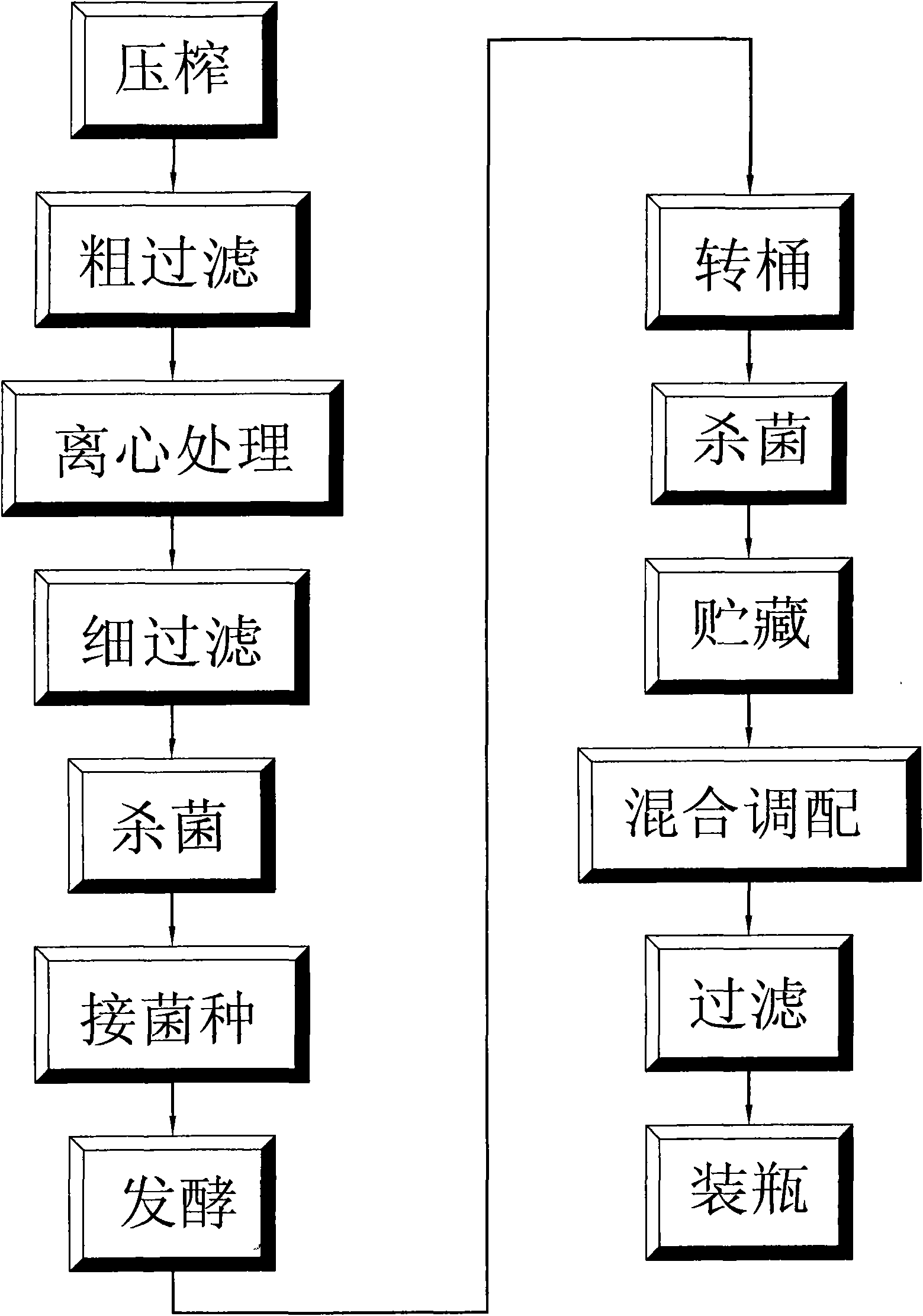

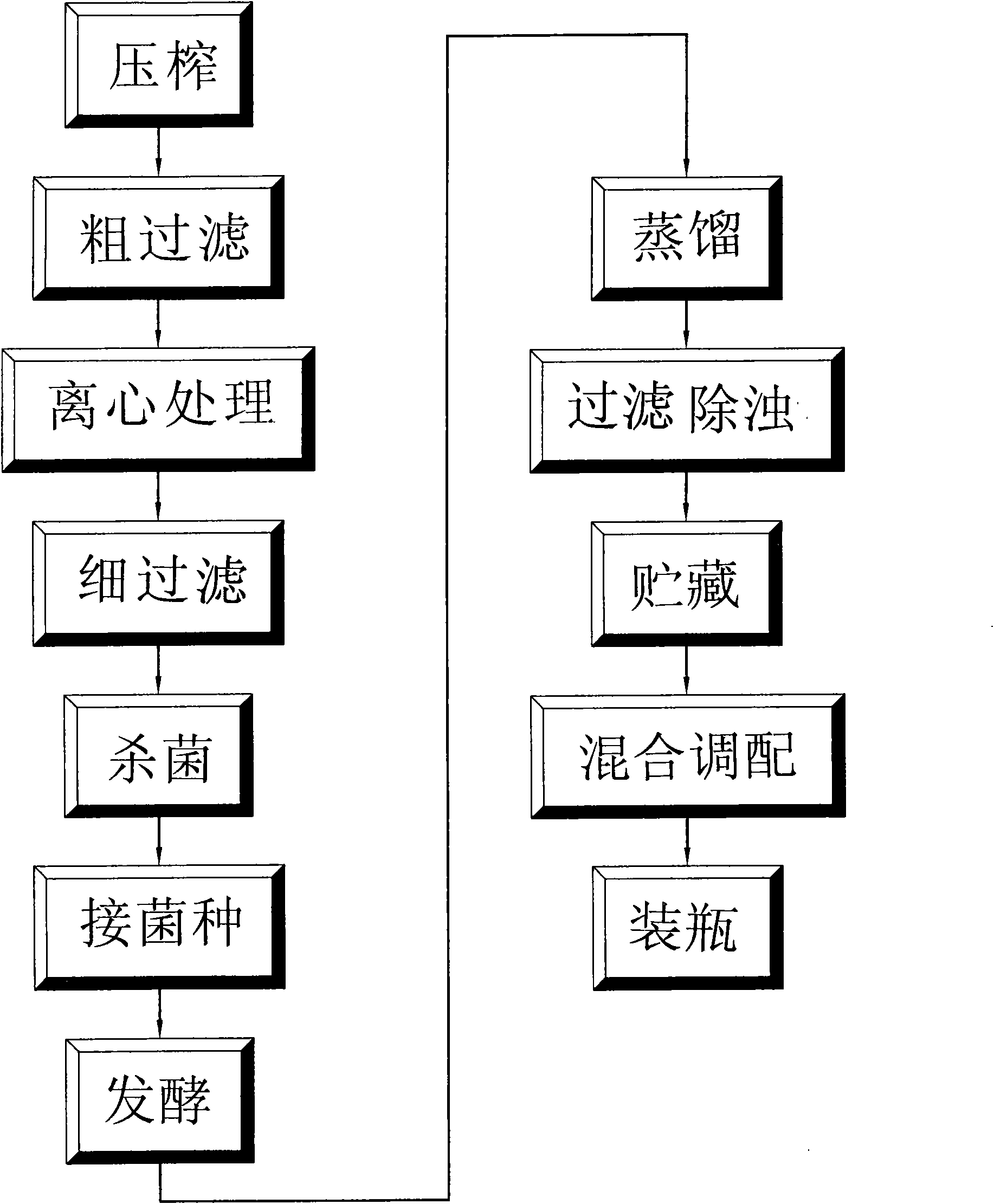

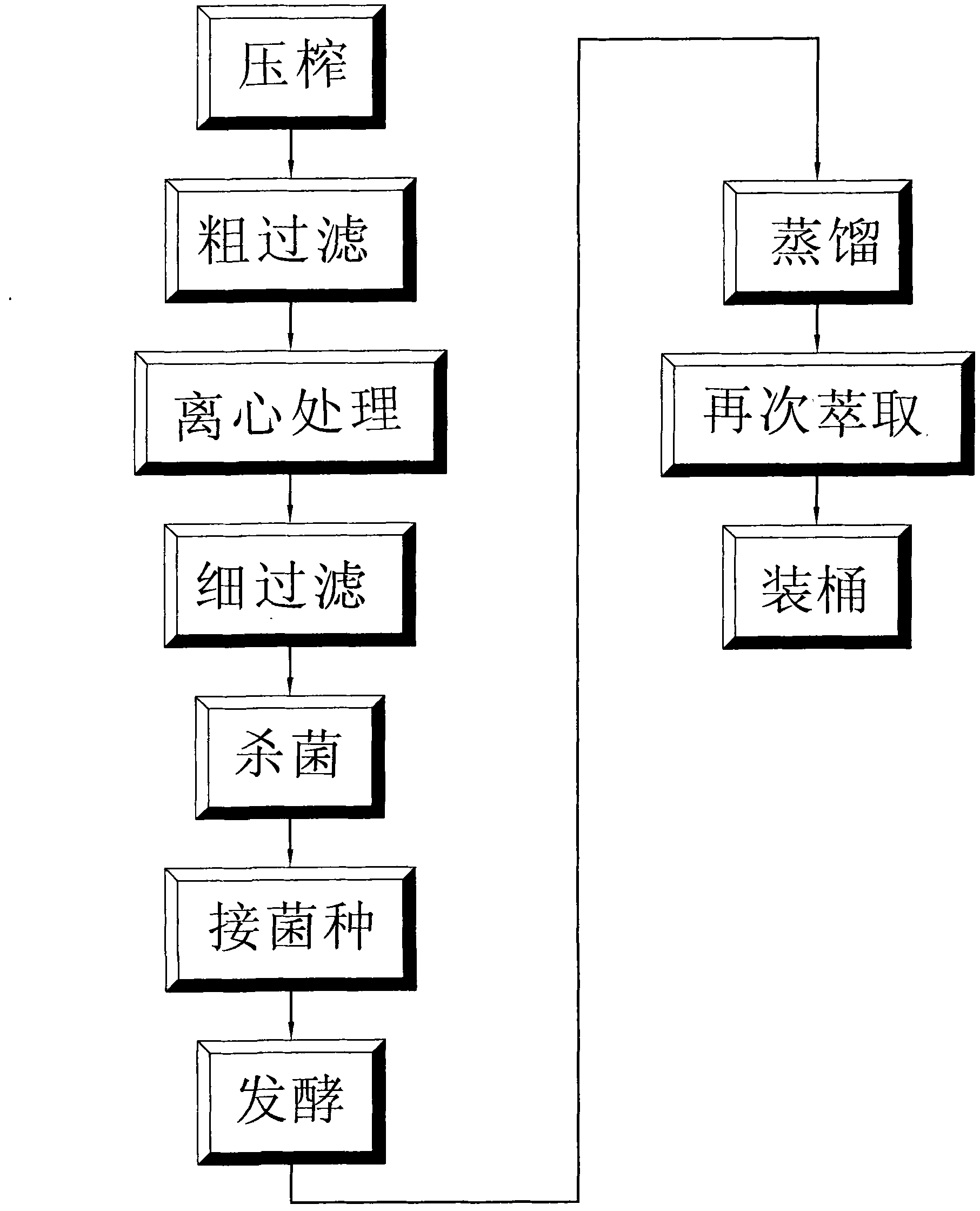

[0070] First, see figure 1 The schematic flow chart of the present invention illustrates a preferred embodiment of the present invention using the brewing method to make wine. As shown in the figure, the present invention at least includes the following process when utilizing sweet sorghum stalks and leaf juice to brew wine:

[0071] (A) Squeeze: Squeeze the sweet sorghum stalks and leaves obtained by green mowing to squeeze out green juice and fiber;

[0072] (B) Coarse filtration: the fibers of sorghum stalks and leaves are filtered out;

[0073] (C) centrifugal treatment: utilize centrifuge to carry out centrifugal treatment to the juice that filter fiber, to extract purer juice;

[0074] (D) Fine filtration: further filter out the fine residue contained in the juice;

[0075] (E) Sterilization: high temperature kills the natural miscellaneous bacteria that may be contained in the juice;

[0076] (F) Inoculated strains: insert the strains of the preset drinking flavor (p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com