Fluorin-containing POSS acrylate polymer, preparation method thereof and paint

An acrylate and copolymer technology, applied in the field of acrylate copolymer resin and its synthesis, can solve the problems of high cost, poor antifouling ability of coatings, complex process, etc., and achieve improved utilization rate, high antifouling ability, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a kind of preparation method of fluorine-containing POSS acrylate copolymer, comprises the following steps:

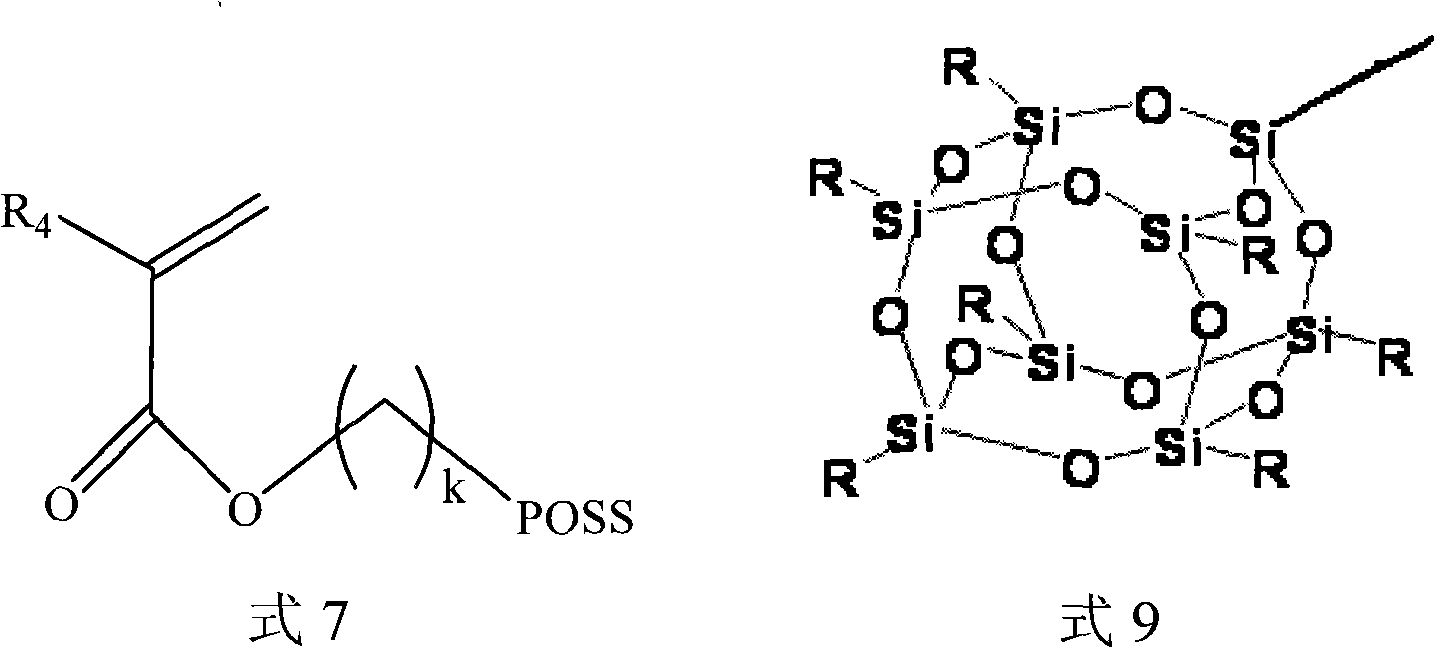

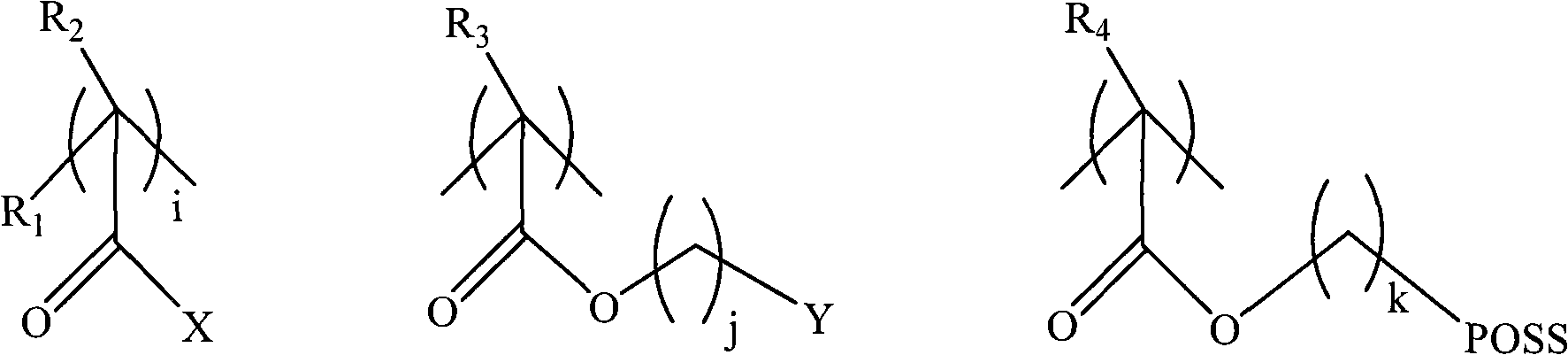

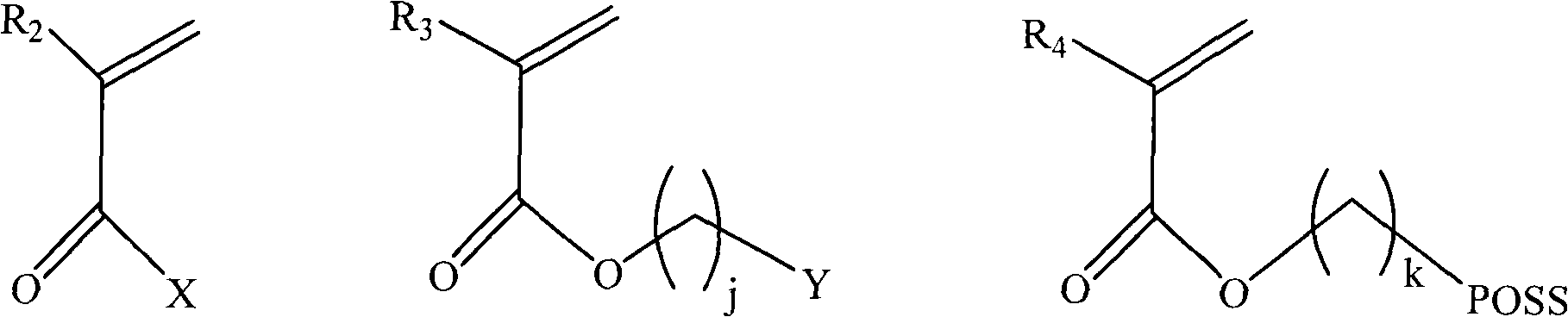

[0043] (a) contact the polymerizable monomer with the initiator, and carry out the polymerization reaction under the protection of nitrogen. The monomers of the structures shown in formula 6 and formula 7 are contained in the polymerizable monomer, and the product obtained after the polymerization reaction is completed is denoted as A;

[0044] (b) Add mixture B to A, which contains fluorine-containing acrylate monomer and fluorine-containing solvent shown in formula 5, and obtains fluorine-containing POSS acrylate copolymer by free radical polymerization;

[0045]

[0046] Formula 5 Formula 6 Formula 7

[0047] Among them, R 2 , R 3 , R 4 Each independently is H, C 1 -C 5 straight-chain or branched-chain alkyl;

[0048] X = -OCH 2 (CH 2 ) m CH 2 (CF 2 ) n CF 3 ;

[0049] Y = -COOH, -OH or

[0050] j and n ...

Embodiment 1

[0079] This embodiment is used to illustrate the fluorine-containing POSS acrylate copolymer provided by the present invention and its preparation method.

[0080] (1) After the dry 250ml four-necked flask was equipped with mechanical stirring and a reflux condenser, nitrogen gas was passed for 10 minutes; 16.5g of polymerizable monomers (including 10.5g of methyl methacrylate and 2g of acrylic acid) were added to the four-necked flask. Isobutyl ester, 1g hydroxyethyl acrylate, 3g POSS acrylate (k=5, R in formula 7 4 =-CH 3 , R=-C in Formula 9 4 h 9 ), 0.3g initiator AIBN and 30g. solvent toluene; vigorously stirred, under the protection of nitrogen, reacted at 85°C for 3h;

[0081] (2) Then, in the reaction system of step (1), slowly dropwise add 3.875g fluorine-containing acrylate (20% by mass perfluorooctyl ethyl acrylate), 0.18g initiator AIBN and 5g solvent toluene, 10g containing Fluorine solvent FHT-6500, the dropping time is 50 minutes, and the reaction is continue...

Embodiment 2

[0083] This embodiment is used to illustrate the fluorine-containing POSS acrylate copolymer provided by the present invention and its preparation method.

[0084] Adopt the method identical with embodiment 1 to prepare fluorine-containing POSS acrylate copolymer, difference is: in step (1), only contain 2g hydroxyethyl acrylate, 4g POSS acrylate (in formula 7) in the polymerizable monomer k=5, R 4 =-CH 3 , R=-C in Formula 9 4 h 9 ), i=5, Y=-CH 3 ), 0.2g initiator AIBN and 15g. solvent toluene; in step (2), slowly add 6g fluorine-containing acrylate (50 mass % perfluorooctyl ethyl acrylate), 0.24g initiator AIBN and 5g solvent toluene , 15g fluorine-containing solvent FHT-6500; finally obtained fluorine-containing POSS acrylate copolymer, denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com