Method for preparing silicoaluminophosphate (SAPO)-34 molecular sieve molded catalyst, product prepared by method and application of product

A SAPO-34 and catalyst technology, which is applied in the field of preparing SAPO-34 molecular sieve shaped catalysts to achieve the effects of protecting the ecological environment, saving equipment investment and reducing extra-molecular diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

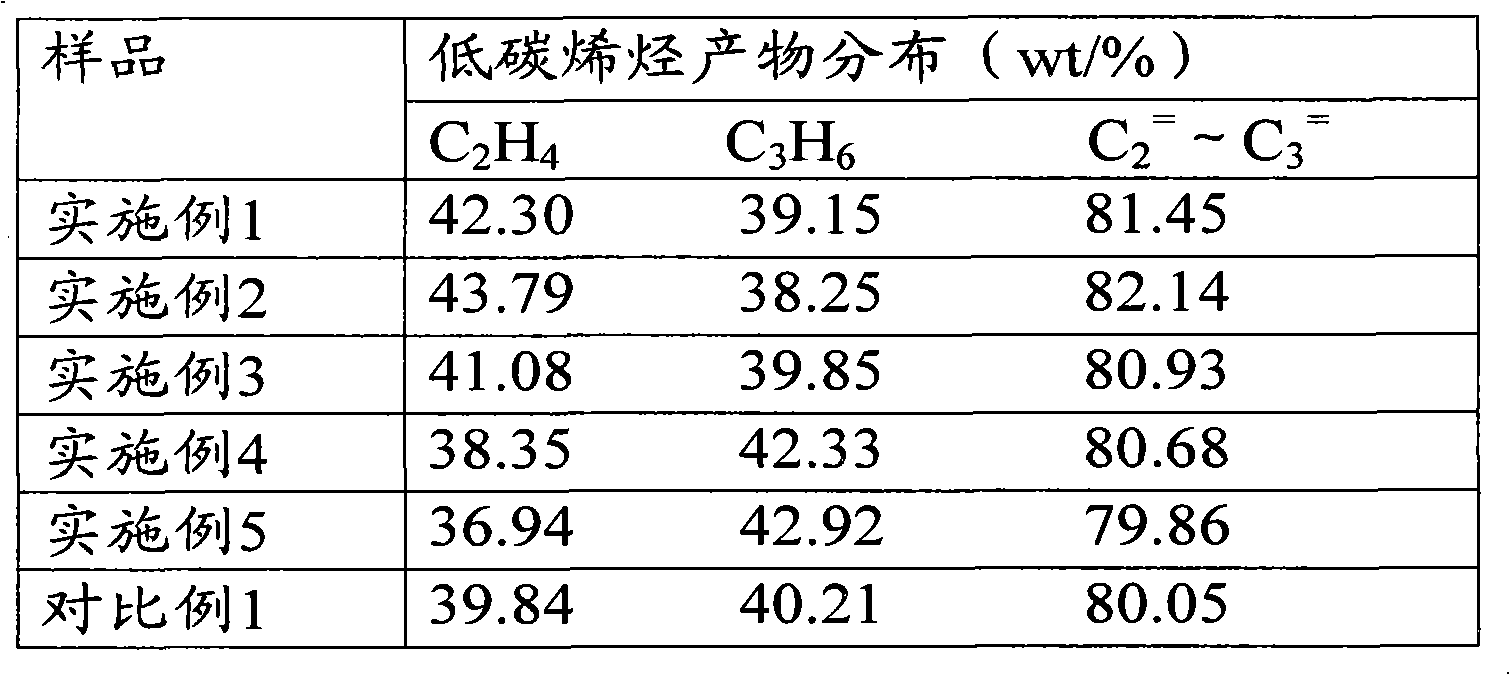

Examples

Embodiment 1

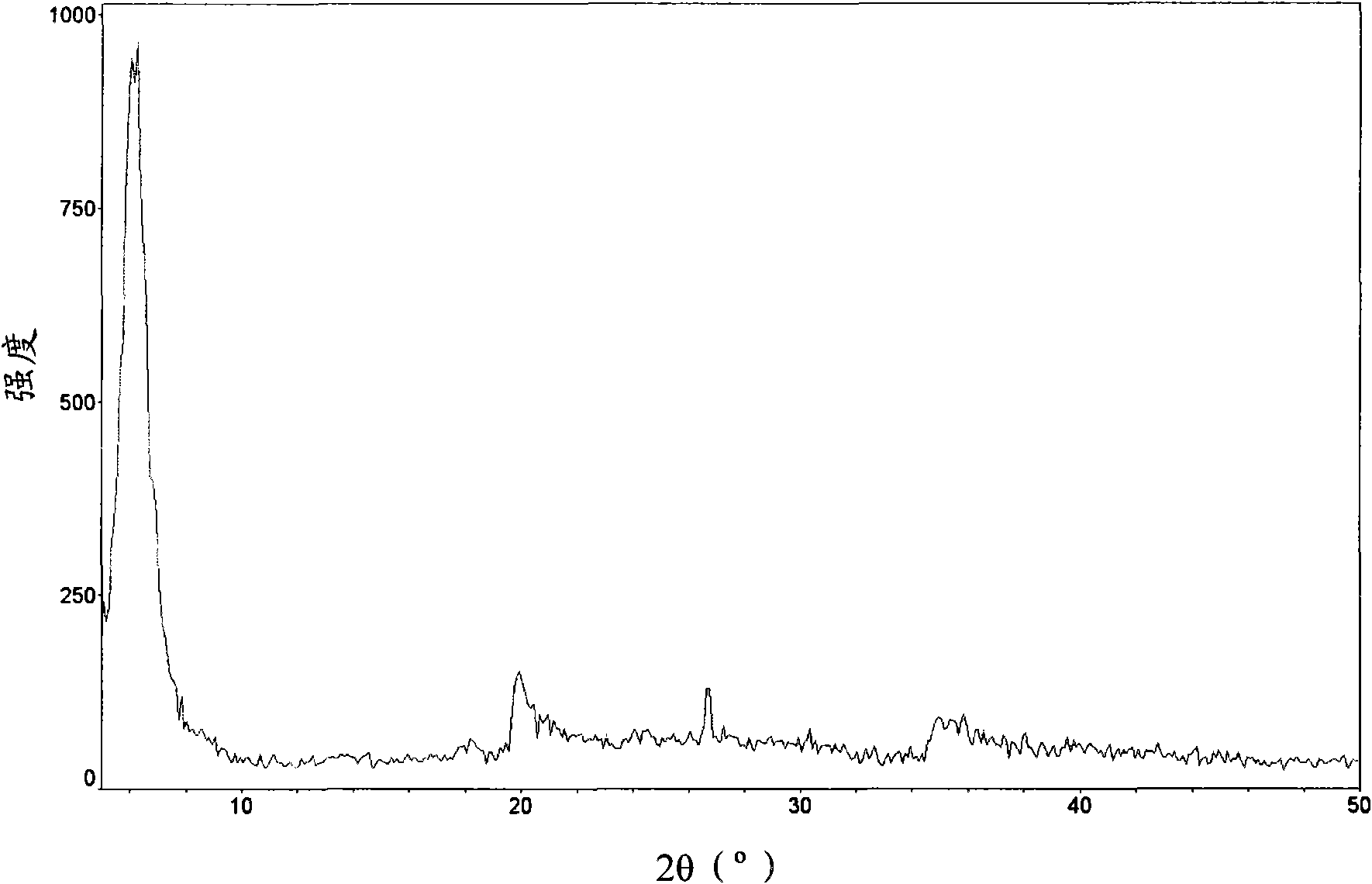

[0104] Add 4.23g of montmorillonite to 25ml of 0.2M NaOH solution. The montmorillonite was activated in alkaline solution for 4h. Weigh 30 g of triethylamine, add it into the above solution, and react the triethylamine with the silicon in the activated solution or the silicon source on the surface of the activated montmorillonite. Dissolve 9g of pseudo-boehmite in 18g of water, add the pseudo-boehmite slurry into the mixed solution of montmorillonite and triethylamine, and stir for 30 minutes. Take 14.61g of 85% phosphoric acid, add it to the above solution, and stir for 2h. After the crystallization stock solution was aged for 2 hours, it was hydrothermally crystallized at 200°C for 72 hours. After chilling, filter, wash, dry, and activate by roasting at 600°C for 4h. The XRD characterization results showed that the obtained product was a silicoaluminophosphate molecular sieve.

[0105] figure 2 XRD spectrum of SAPO-34 molecular sieve synthesized in situ from montmorill...

Embodiment 2

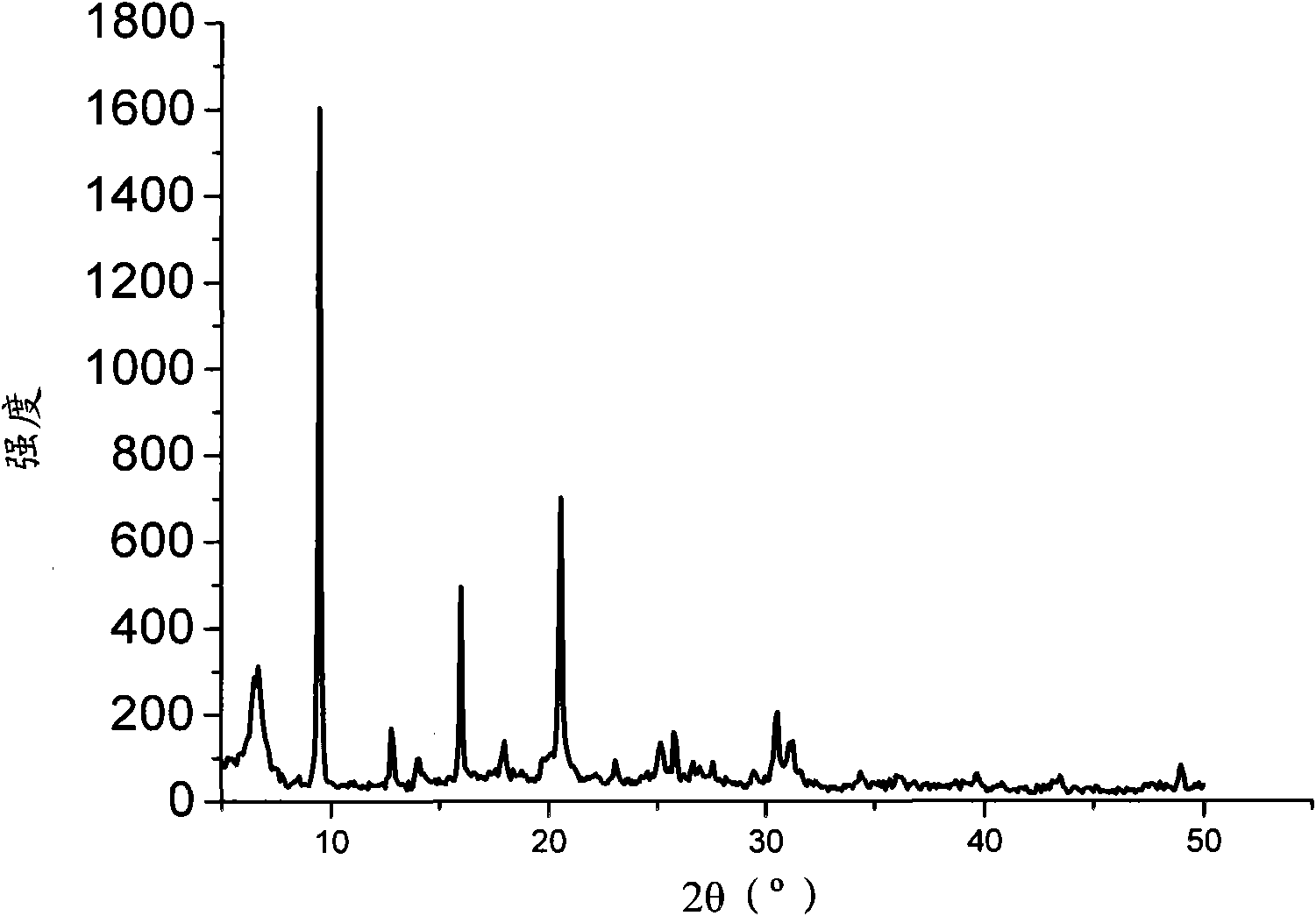

[0109] Add 4.23g of montmorillonite to 25ml of 0.2M NaOH solution. The montmorillonite was activated in alkaline solution for 4h. Weigh 30 g of triethylamine, add it into the above solution, and react the triethylamine with the activated solution silicon or surface silicon. Dissolve 9 g of pseudo-boehmite in 18 g of water, add the slurry of pseudo-boehmite into the activated montmorillonite solution, and stir for 30 minutes. Weigh 14.61 g of 85% phosphoric acid, add to the above solution, and stir for 2 h. After the crystallization stock solution was aged for 2 hours, it was poured into a hydrothermal crystallization kettle, and hydrothermally crystallized at 200° C. for 48 hours. After chilling, filter, wash, dry, and activate by roasting at 600°C for 4h. XRD characterization results showed that the obtained product was SAPO-34 molecular sieve.

Embodiment 3

[0111] Add 4.23g of montmorillonite to 25ml of 0.2M NaOH solution. The montmorillonite was activated in alkaline solution for 4h. Weigh 30 g of triethylamine, add it into the above solution, and react the triethylamine with the activated solution silicon or surface silicon. Dissolve 9 g of pseudo-boehmite in 18 g of water, add the slurry of pseudo-boehmite into the activated montmorillonite solution, and stir for 30 minutes. Weigh 14.61 g of 85% phosphoric acid, add to the above solution, and stir for 2 h. After the crystallization stock solution was aged for 2 hours, it was poured into a hydrothermal crystallization kettle, and hydrothermally crystallized at 200° C. for 96 hours. After chilling, filter, wash, dry, and activate by roasting at 600°C for 4h. XRD characterization results showed that the obtained product was SAPO-34 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com