Alcohol end capping nonionic polyurethane cross-linking agent and preparation method and application thereof

A polyurethane crosslinking agent, non-ionic technology, used in polyurea/polyurethane adhesives, polyurea/polyurethane coatings, adhesive types, etc., can solve the problem of high dissociation temperature of closed products, free formaldehyde environmental pollution, High price and other problems, to achieve the effect of good freeze-thaw stability, good freeze-thaw stability, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

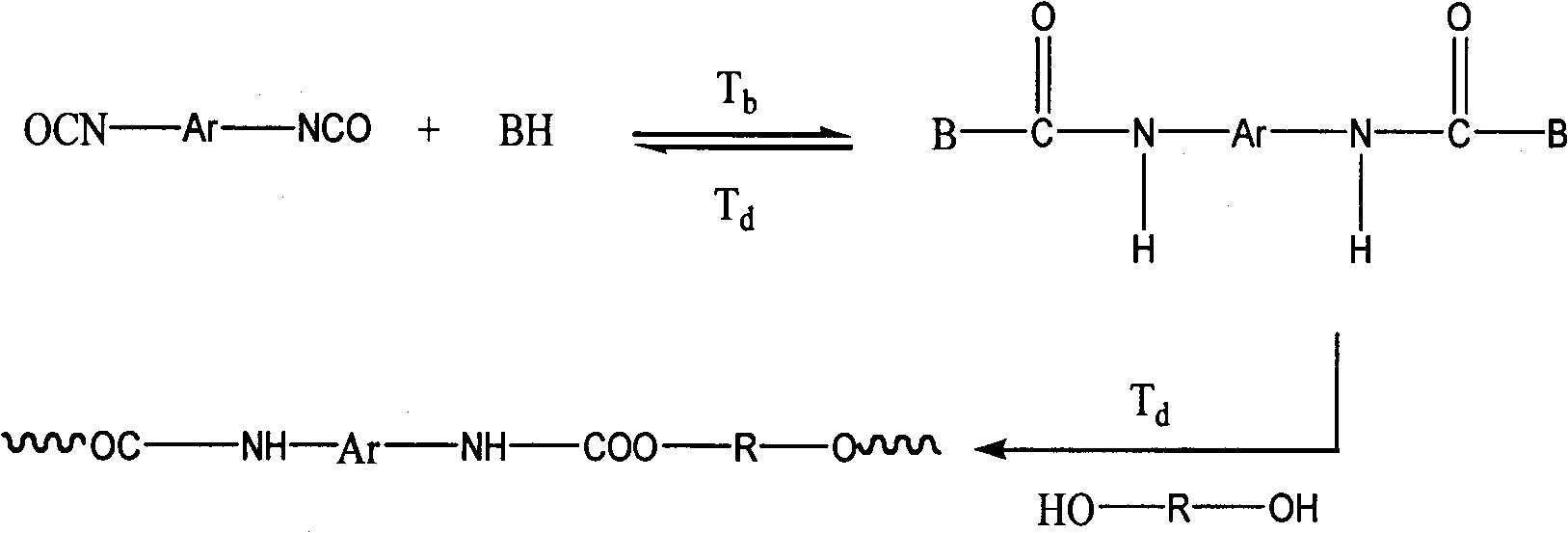

Method used

Image

Examples

Embodiment 1

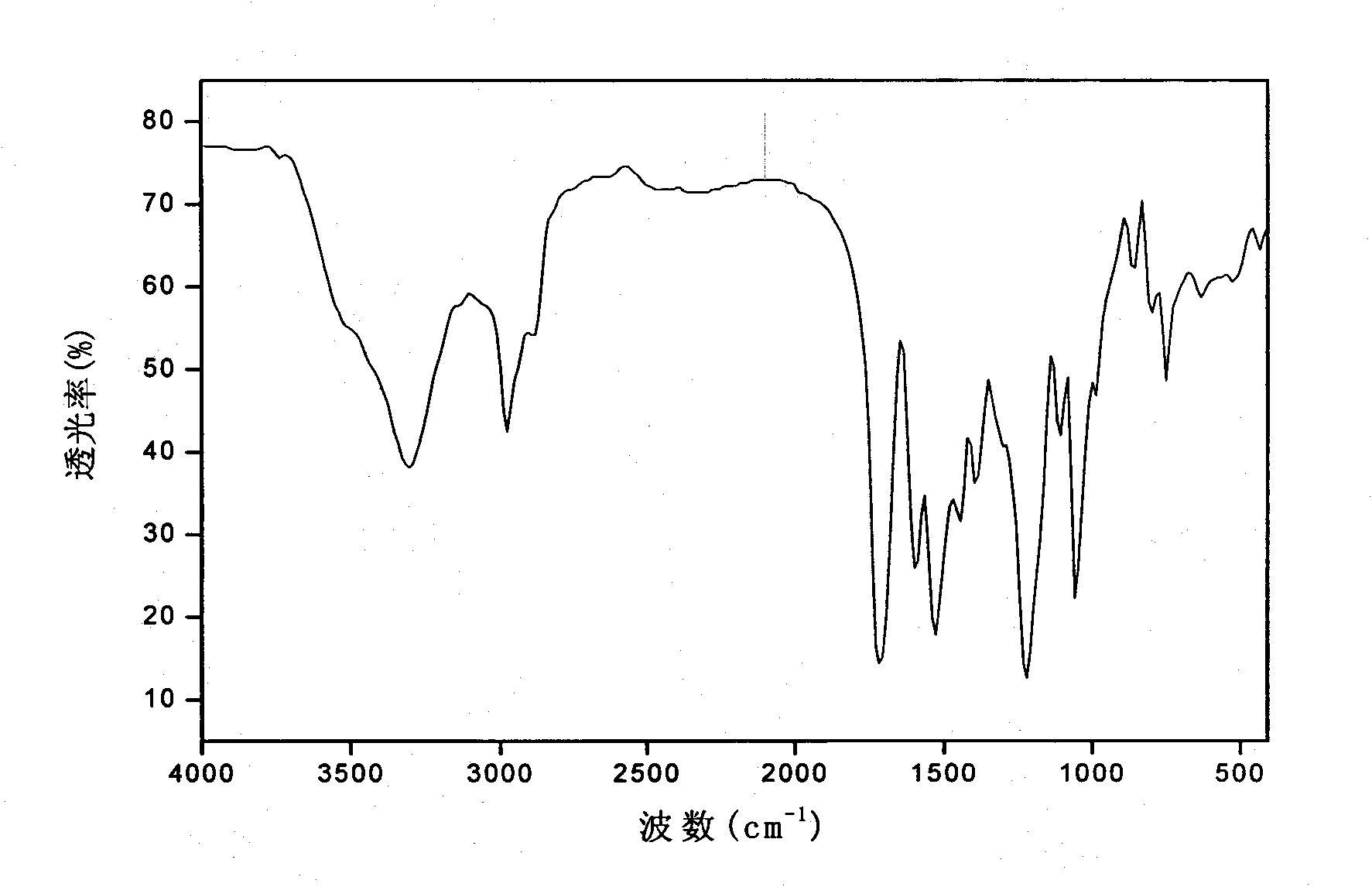

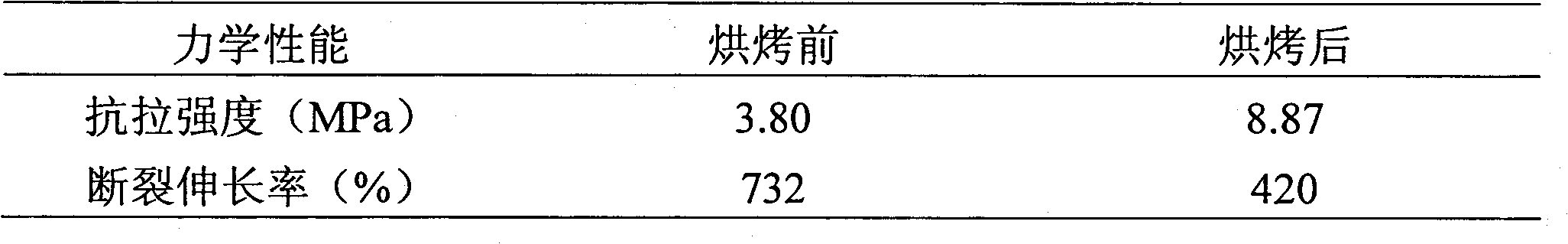

[0040]Mix 0.1mol TDI (2,4-toluene diisocyanate), 0.05mol PEG1000 (polyethylene glycol 1000), 0.02mol TMP (trimethylolpropane), 25ml acetone and 2 drops (20 drops are 1ml, ie 0.2wt %) stannous octoate was added in a 250ml four-necked round-bottomed flask equipped with a stirrer, an air duct, and a condenser, and reacted at 40°C for 6h; the temperature was raised to 60°C, and 0.045mol ethylene glycol monoethyl ether was added, and reacted for 5 hours Until the NCO group is completely blocked, it is detected by infrared detection at 2250-2270cm -1 There is no characteristic absorption peak of the NCO group; the temperature is lowered to 25 degrees, and water is added under stirring at 1500rpm for dispersion to obtain an aqueous dispersion of alcohol-terminated nonionic polyurethane crosslinking agent, which is a light yellow transparent viscous liquid. The solid content is 30%, the pH is 6.7, and the viscosity is 185Cps. The infrared spectrogram of the prepared alcohol-terminate...

Embodiment 2

[0042] Mix 0.1mol TDI (2,4-toluene diisocyanate), 0.02mol PEG1000 (polyethylene glycol 1000), 0.005mol TMP (trimethylolpropane), 20ml methyl ethyl ketone and 2 drops (20 drops are 1ml, that is, 0.2 wt%) stannous acid was added with a stirrer, in the 250ml four-necked round bottom flask of air duct and condenser, and reacted for 3h at 80°C; the temperature was raised to 90°C, and 0.16mol ethylene glycol monoethyl ether was added to react 2 Hours until the NCO group is completely blocked, by infrared detection, at 2250 ~ 2270cm -1 There is no characteristic absorption peak of the NCO group; the temperature is lowered to 20 degrees, and water is added under stirring at 1500rpm for dispersion to obtain an aqueous dispersion of alcohol-terminated nonionic polyurethane crosslinking agent, which is a light yellow transparent viscous liquid. Solid content is 30%, pH7.3, viscosity 160Cps. The infrared spectrum of the prepared alcohol-terminated nonionic polyurethane crosslinking agent...

Embodiment 3

[0044] Mix 0.1mol IPDI (isophorone diisocyanate), 0.04mol PPG1000 (polypropylene glycol 1000), 0.01mol glycerin, 15ml N-methylpyrrolidone and 2 drops (20 drops are 1ml, ie 0.2wt%) dilaurate dilaurate Add butyltin into a 250ml four-necked round-bottomed flask equipped with a stirrer, an air duct, and a condenser, and react at 60°C for 5h; raise the temperature to 80°C, add 0.1mol ethylene glycol monobutyl ether, and react for 3 hours until the NCO group The group is completely blocked, and after infrared detection, it is at 2250-2270cm -1 There is no characteristic absorption peak of the NCO group; the temperature is lowered to 30 degrees, and water is added under stirring at 1500 rpm to disperse to obtain an aqueous dispersion of alcohol-terminated nonionic polyurethane crosslinking agent, which is a light yellow transparent viscous liquid. The solid content is 30%, the pH is 6.1, and the viscosity is 140Cps. The infrared spectrum of the prepared alcohol-terminated nonionic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com