Alcohol end capping nonionic polyurethane cross-linking agent and preparation method and application thereof

A polyurethane crosslinking agent, non-ionic technology, applied in polyurea/polyurethane adhesives, polyurea/polyurethane coatings, adhesive types, etc., can solve the problem of high dissociation temperature, high price and free aldehyde Environmental pollution and other problems, to achieve the effect of good freeze-thaw stability, good heat resistance stability, and good freeze-thaw stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

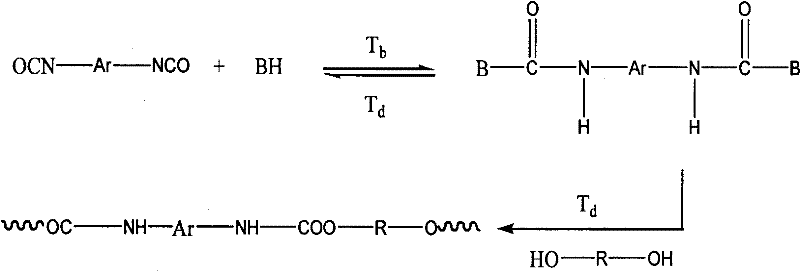

Method used

Image

Examples

Embodiment 1

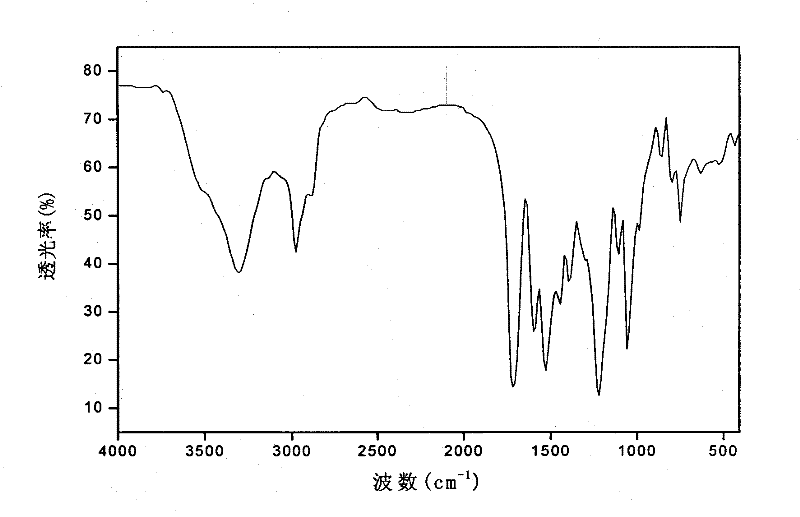

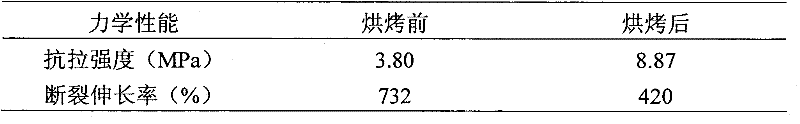

[0040]Mix 0.1mol TDI (2,4-toluene diisocyanate), 0.05mol PEG1000 (polyethylene glycol 1000), 0.02mol TMP (trimethylolpropane), 25ml acetone and 2 drops (20 drops are 1ml, ie 0.2wt %) stannous octoate was added in a 250ml four-necked round-bottomed flask equipped with a stirrer, an air duct, and a condenser, and reacted at 40°C for 6h; the temperature was raised to 60°C, and 0.045mol ethylene glycol monoethyl ether was added, and reacted for 5 hours Until the NCO group is completely blocked, it is detected by infrared detection at 2250-2270cm -1 There is no characteristic absorption peak of the NCO group; the temperature is lowered to 25 degrees, and water is added under stirring at 1500rpm for dispersion to obtain an aqueous dispersion of alcohol-terminated nonionic polyurethane crosslinking agent, which is a light yellow transparent viscous liquid. The solid content is 30%, the pH is 6.7, and the viscosity is 185Cps. The infrared spectrogram of the prepared alcohol-terminate...

Embodiment 2

[0042] Mix 0.1mol TDI (2,4-toluene diisocyanate), 0.02mol PEG1000 (polyethylene glycol 1000), 0.005mol TMP (trimethylolpropane), 20ml methyl ethyl ketone and 2 drops (20 drops are 1ml, that is, 0.2 wt%) stannous acid was added with a stirrer, in the 250ml four-necked round bottom flask of air duct and condenser, and reacted for 3h at 80°C; the temperature was raised to 90°C, and 0.16mol ethylene glycol monoethyl ether was added to react 2 Hours until the NCO group is completely blocked, by infrared detection, at 2250 ~ 2270cm -1 There is no characteristic absorption peak of the NCO group; the temperature is lowered to 20 degrees, and water is added under stirring at 1500rpm for dispersion to obtain an aqueous dispersion of alcohol-terminated nonionic polyurethane crosslinking agent, which is a light yellow transparent viscous liquid. Solid content is 30%, pH7.3, viscosity 160Cps. The infrared spectrum of the prepared alcohol-terminated nonionic polyurethane crosslinking agent...

Embodiment 3

[0044] Mix 0.1mol IPDI (isophorone diisocyanate), 0.04mol PPG1000 (polypropylene glycol 1000), 0.01mol glycerin, 15ml N-methylpyrrolidone and 2 drops (20 drops are 1ml, ie 0.2wt%) dilaurate dilaurate Add butyltin into a 250ml four-necked round-bottomed flask equipped with a stirrer, an air duct, and a condenser, and react at 60°C for 5h; raise the temperature to 80°C, add 0.1mol ethylene glycol monobutyl ether, and react for 3 hours until the NCO group The group is completely blocked, and after infrared detection, it is at 2250-2270cm -1 There is no characteristic absorption peak of the NCO group; the temperature is lowered to 30 degrees, and water is added under stirring at 1500 rpm to disperse to obtain an aqueous dispersion of alcohol-terminated nonionic polyurethane crosslinking agent, which is a light yellow transparent viscous liquid. The solid content is 30%, the pH is 6.1, and the viscosity is 140Cps. The infrared spectrum of the prepared alcohol-terminated nonionic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com