Preparation method of polyester modified epoxy resin for household electroplate primer

A technology for modification of epoxy resin and polyester, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor flexibility, adhesion, poor MEK resistance and salt spray resistance, and primers that cannot meet the requirements of home appliance boards Requirements and other issues, to achieve the effect of improving performance, improving interlayer adhesion, and excellent salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

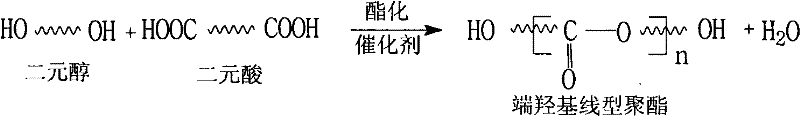

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 prepares polyester resin 1#

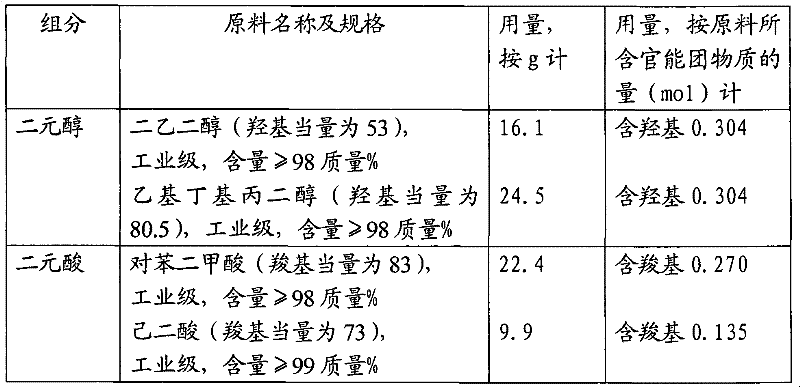

[0031] (A) The raw material formula is shown in Table 1

[0032] Table 1

[0033]

[0034]

[0035]Note: The amount of dibasic alcohol and dibasic acid in the formula is based on the amount of carboxyl substances and hydroxyl substances contained in it. 1 mole of carboxyl uses 1.50 moles of hydroxyl. Among them, the amount of diethylene glycol and ethyl butyl propylene glycol The ratio is 1:1; the molar ratio of terephthalic acid to adipic acid is 2:1.

[0036] (B) specific operation

[0037] Put the dibasic alcohol, dibasic acid, catalyst and solvent xylene in the clean reaction bottle. After the materials are melted, start stirring and pass inert gas at the same time. The material is heated slowly at a rate of 10°C / h, kept at 200°C for 1 to 2 hours, then slowly raised to 220°C and kept for reaction until the measured acid value is less than 2mgKOH / g, then vacuumed for 0.5h to remove small molecule alcohols. Cool dow...

Embodiment 2

[0038] Embodiment 2 prepares polyester resin 2#

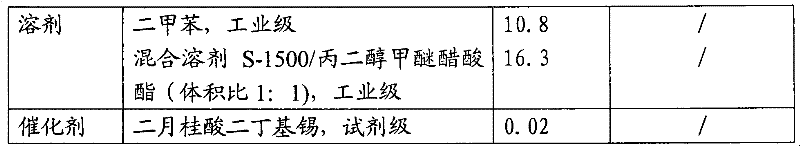

[0039] (A) The raw material formula is shown in Table 2

[0040] Table 2

[0041]

[0042] Note: The amount of dibasic alcohol and dibasic acid in the formula is calculated as 1.20 moles of hydroxyl for 1 mole of carboxyl group according to the amount of carboxyl substance and hydroxyl substance contained in it. Among them, the ratio of the amount of methylpropanediol to neopentyl glycol 6:1; the molar ratio of isophthalic acid to adipic acid is 5:1.

[0043] (B) specific operation

[0044] According to the formula of table 2 and the operation gained filtrate of embodiment 1 is hydroxyl-terminated linear polyester resin, referred to as polyester resin 2#, its hydroxyl equivalent is 600 (equivalent hydroxyl value 93.5mgKOH / g), relative number average molecular weight The mass is 1200, the solid content is 70% (mass), and it is preserved for future use.

Embodiment 3

[0045] Embodiment 3 prepares polyester resin 3#,

[0046] (A) The raw material formula is shown in Table 3

[0047] table 3

[0048]

[0049] Note: The amount of dibasic alcohols and dibasic acids in the formula is based on the amount of carboxyl substances and hydroxyl substances contained in them. 1 mole of carboxyl uses 1.07 moles of hydroxyl. Among them, the ratio of ethylene glycol and 1,6 hexanediol The molar ratio is 2:1; the molar ratio of isophthalic acid to adipic acid is 3:1.

[0050] (B) specific operation

[0051] According to the formula of table 3 and the operation gained filtrate of embodiment 1 is hydroxyl-terminated linear polyester resin, referred to as polyester resin 3#, its hydroxyl equivalent is 1450 (equivalent hydroxyl value 38.7mgKOH / g), relative number average molecular weight The mass is 2900, the solid content is 60% (mass), and it is preserved for future use.

[0052] (2) Preparation of polyester modified epoxy resin

[0053] It is impleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com