Smooth-surfaced gelatin microsphere and preparation method

A technology with smooth surface and gelatin, which is applied in the field of smooth surface gelatin microspheres and preparation, can solve the problems of poor surface smoothness of gelatin microspheres, large consumption of surfactants, organic solvents and oils, and achieves efficient preparation and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

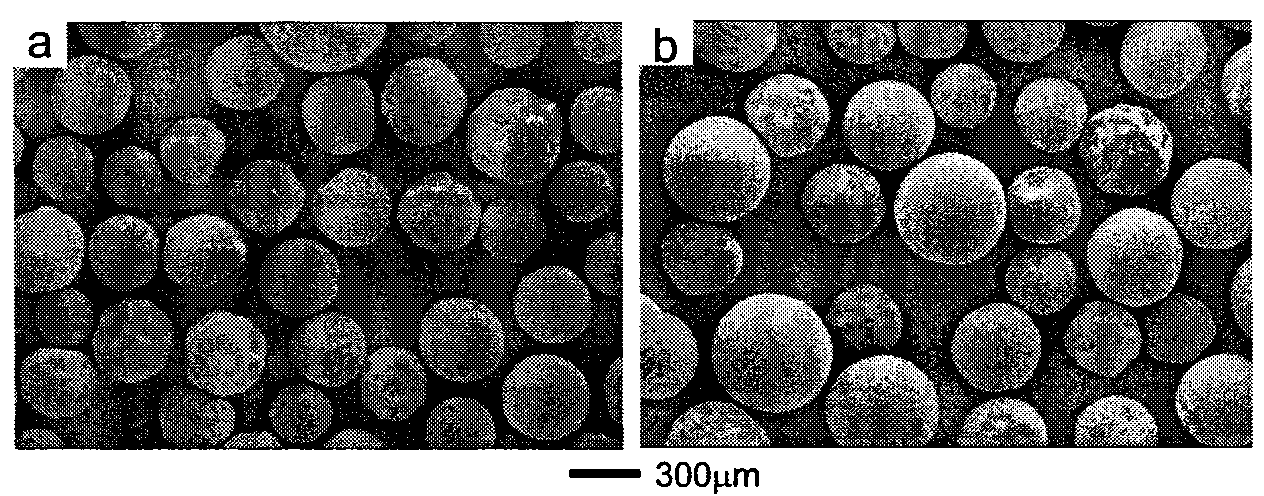

Embodiment 1

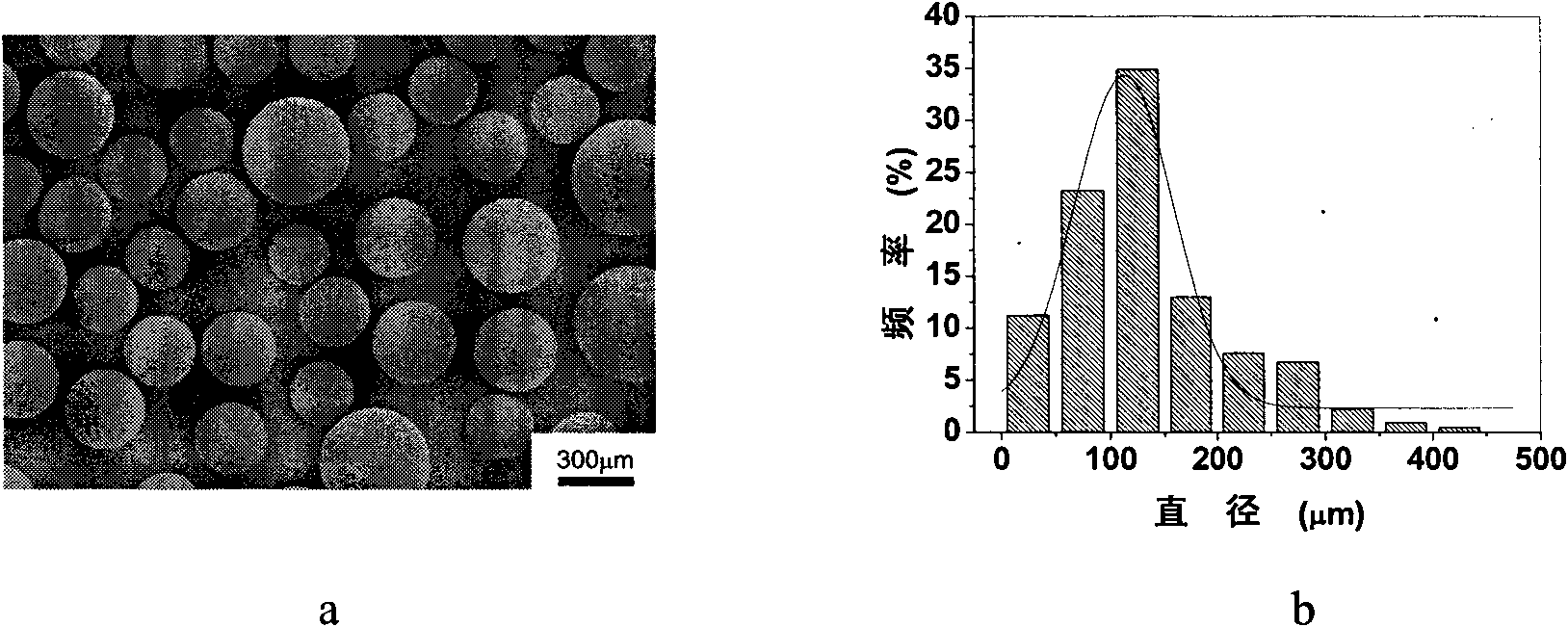

[0016] Dissolve 10g of gelatin in 25ml of 70°C distilled water to prepare a solution with a concentration of 0.4g / ml; add 150ml of liquid paraffin into a 500ml round bottom flask, keep it in a 70°C water bath for 60 minutes, and make the temperature reach 70°C; stir it mechanically (3000r / min), pour the gelatin aqueous solution into the above-mentioned 70°C liquid paraffin, and emulsify for 15 minutes; immediately pour the above-mentioned mixed solution into 100ml of pre-cooled (-10~0°C ice-salt bath), stir and cool After reaching below 0°C (60min), add 100ml 75% ethanol (-18°C) to it, stir and dehydrate for 60min, stop stirring and let it stand for 10min to obtain gelatin microspheres at the bottom of the beaker; after 85% ethanol, 95% ethanol, 100% Each 100ml of ethanol was washed three times (15min / time) to remove residual liquid paraffin; air-dried for 3 days to obtain gelatin microspheres. The SEM photo (a) and particle size distribution figure (b) of the resulting gelati...

Embodiment 2

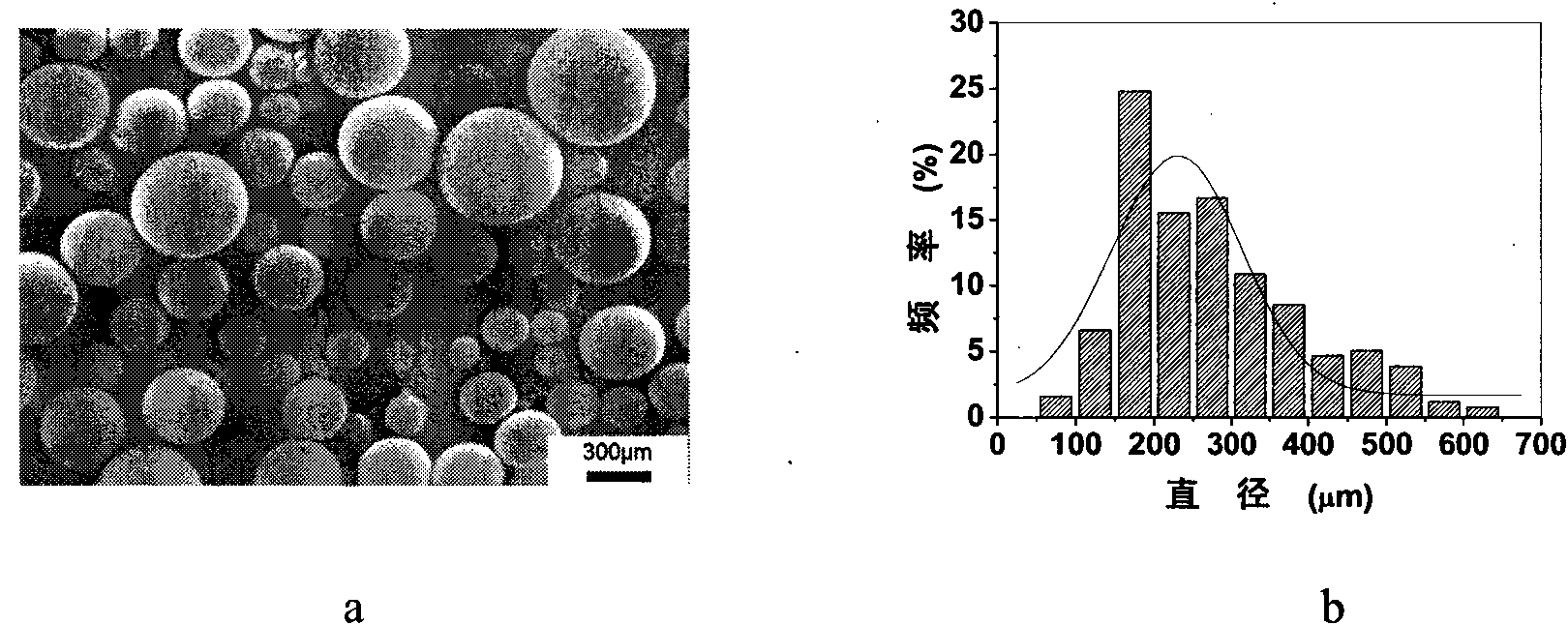

[0018] Dissolve 20g of gelatin in 50ml of 70°C distilled water to prepare a solution with a concentration of 0.4g / ml; add 300ml of liquid paraffin into a 500ml round bottom flask, keep it in a 70°C water bath for 60 minutes, and make the temperature reach 70°C; stir it mechanically (3000r / min), pour the gelatin aqueous solution into the above-mentioned 70°C liquid paraffin, and emulsify for 15 minutes; pour the above-mentioned mixture into a beaker that has been placed in an ice-salt bath (-10~0°C), stir and cool to 0 Below ℃ (60min), add 200ml of 75% ethanol (-18℃) to it, stir and dehydrate for 60min, and get gelatin microspheres at the bottom of the beaker 10min after the stirring stops; wash with 200ml each of 85% ethanol, 95% ethanol, and 100% ethanol Three times (15min / time) to remove residual liquid paraffin; air-dried for 3 days to obtain gelatin microspheres. The SEM photo (a) and particle size distribution figure (b) of the resulting gelatin microspheres are as follow...

Embodiment 3

[0020] Dissolve 3g of gelatin in 20ml of 37°C distilled water to prepare a solution with a concentration of 0.15g / ml; add 200ml of liquid paraffin into a 500ml round bottom flask, keep it in a 37°C water bath for 60 minutes, and make the temperature reach 37°C; stir it mechanically (3000r / min), add gelatin aqueous solution dropwise into liquid paraffin at 37°C, and emulsify for 15 minutes; pour 100ml of liquid paraffin pre-cooled (in an ice-salt bath at -10 to 0°C) into the above mixed solution immediately, and solidify the microspheres After the above mixed solution is cooled to below 0°C (60min), add 100ml of 85% ethanol (-18°C), stir for 60min to dehydrate, and get gelatin microspheres at the bottom of the beaker 10min after the stirring stops; after 90% ethanol, 95% ethanol 100ml each of 100% ethanol was washed three times (15min / time) to remove residual liquid paraffin; air-dried for 3 days to obtain gelatin microspheres. The SEM photo (a) and particle size distribution f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com