Color master batch for hard PVC and preparation method thereof

A technology of color masterbatch and masterbatch, which is applied in the field of color masterbatch for injection molded parts and rigid PVC extrusion, which can solve the problems of pollution and color change of masterbatch, achieve broad application prospects, reduce flow lines, and improve impact performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

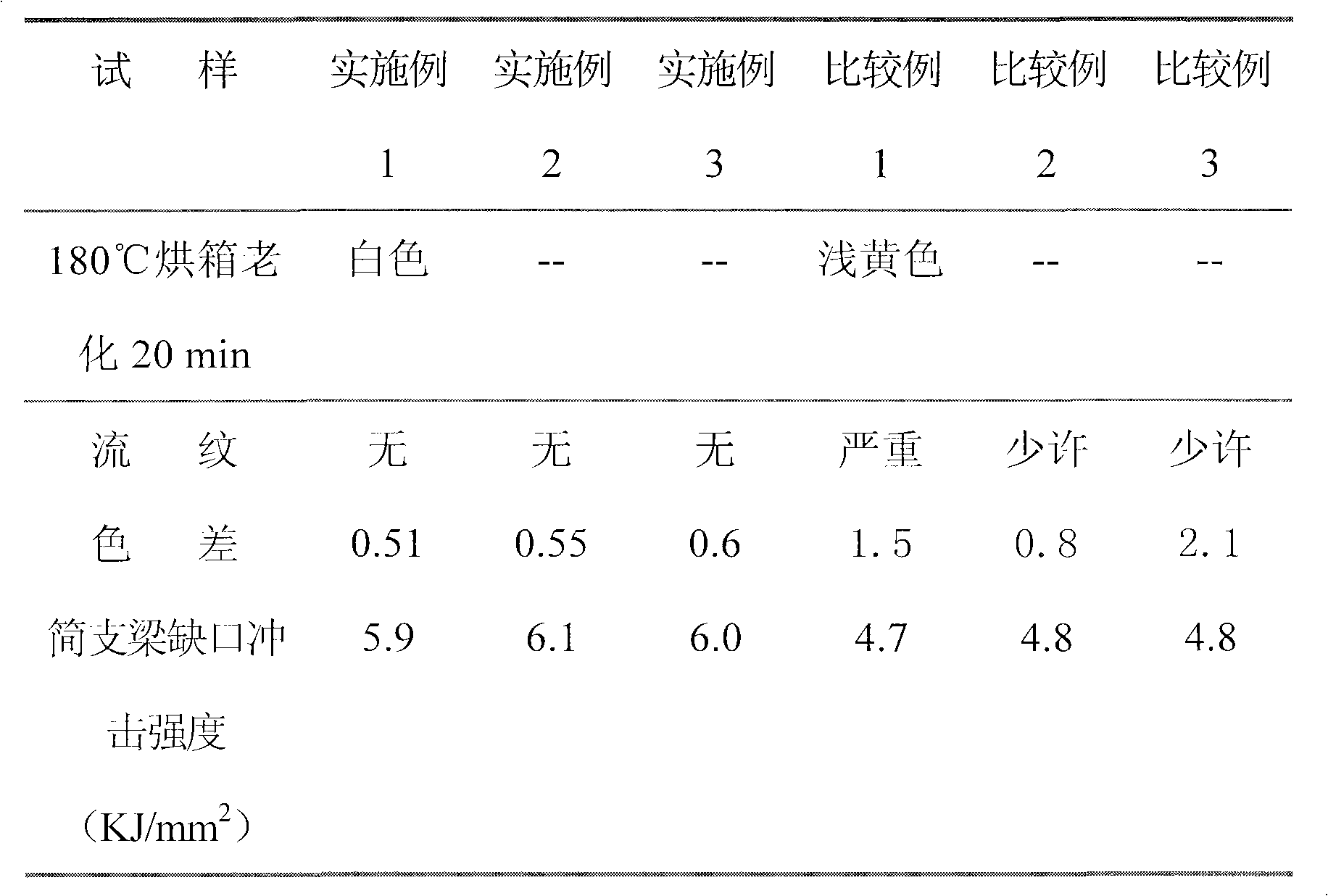

Examples

Embodiment 1

[0018] Under normal temperature and pressure, the following components and percentages by weight: ABS 40%, titanium dioxide 40%, polyethylene wax 8%, MBS 9%, phenolic antioxidant 1076 1%, stearic acid 1%, calcium carbonate 1% %, after grinding into powder, carry out high-speed mixing in a high-speed mixer for 10 minutes, and use a twin-screw extruder to carry out melt blending, the temperature is controlled at 190 ° C, and the screw speed is 200r / min. Refining to disperse the pigment uniformly in the carrier resin, and then carry out granulation, drying, packaging and other processes to obtain the color masterbatch of the present invention.

Embodiment 2

[0020] Under normal temperature and pressure, the following components and weight percentages: AS 25%, SEBS 20%, titanium dioxide 30%, EBS 10%, phosphite 1681%, polysilicone 2%, wollastonite 12%, After being ground into powder, mix at a high speed for 15 minutes in a high-speed mixer, and use a twin-screw extruder for melt blending. The temperature is controlled at 200°C, and the screw speed is 100r / min. The pigment is uniformly dispersed in the carrier resin, and then granulation, drying, packaging and other processes are carried out to obtain the color masterbatch of the present invention.

Embodiment 3

[0022] Under normal temperature and pressure, the following components and weight percentages: PS 5%, K glue 10%, SBS 6%, SEBS 15%, SIS 5%, titanium dioxide 13%, lithopone 5%, azo pigment 0.5% %, oxidized polyethylene wax 5%, paraffin wax 1.5%, monoglyceride 5%, ACR4013%, stearic acid 1%, lanthanum stearate 2%, phenolic antioxidant 1010 1%, phosphite 6263%, DOP 4%, acetyl tributyl citrate 4%, talc powder 5%, barium sulfate 6%, after grinding into powder, mix in a high-speed mixer, first use a banbury mixer to banbury, and then use a screw extruder to make The color masterbatch of the present invention is obtained by granulating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com