Biphenyl-structure-contained epoxy resin/montmorillonite nano composite material

A nano-composite material and epoxy resin technology, which is used in the preparation of nano-composite materials and the field of epoxy resin/montmorillonite nano-composite materials containing biphenyl structure, can solve the problem of poor heat resistance, low glass transition temperature and rigidity. It can overcome the problems of poor heat resistance, reduce the preparation cost, and achieve the effect of good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

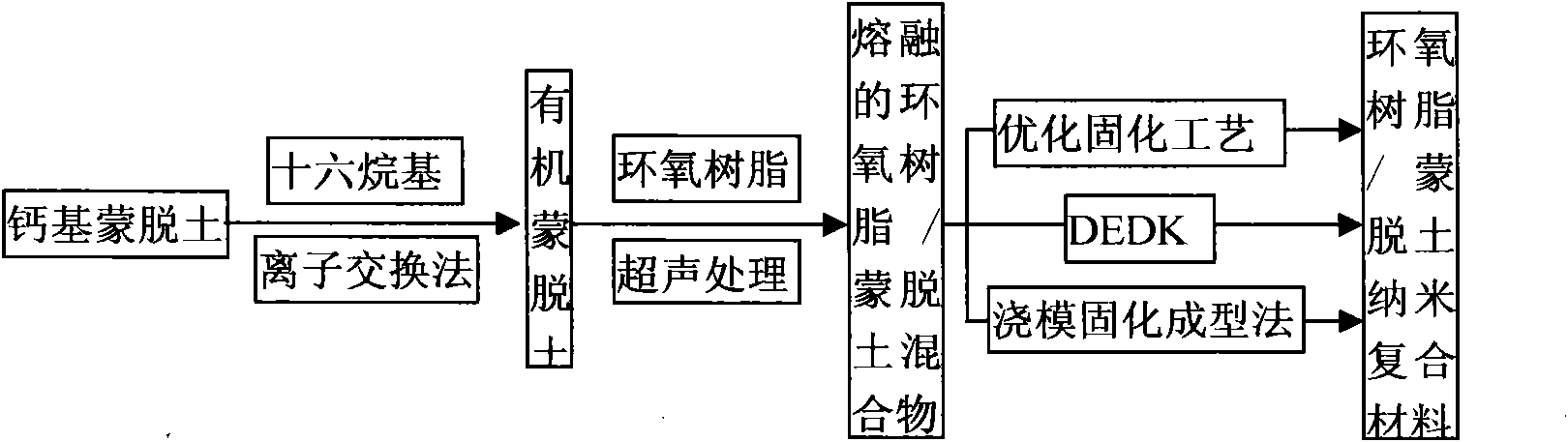

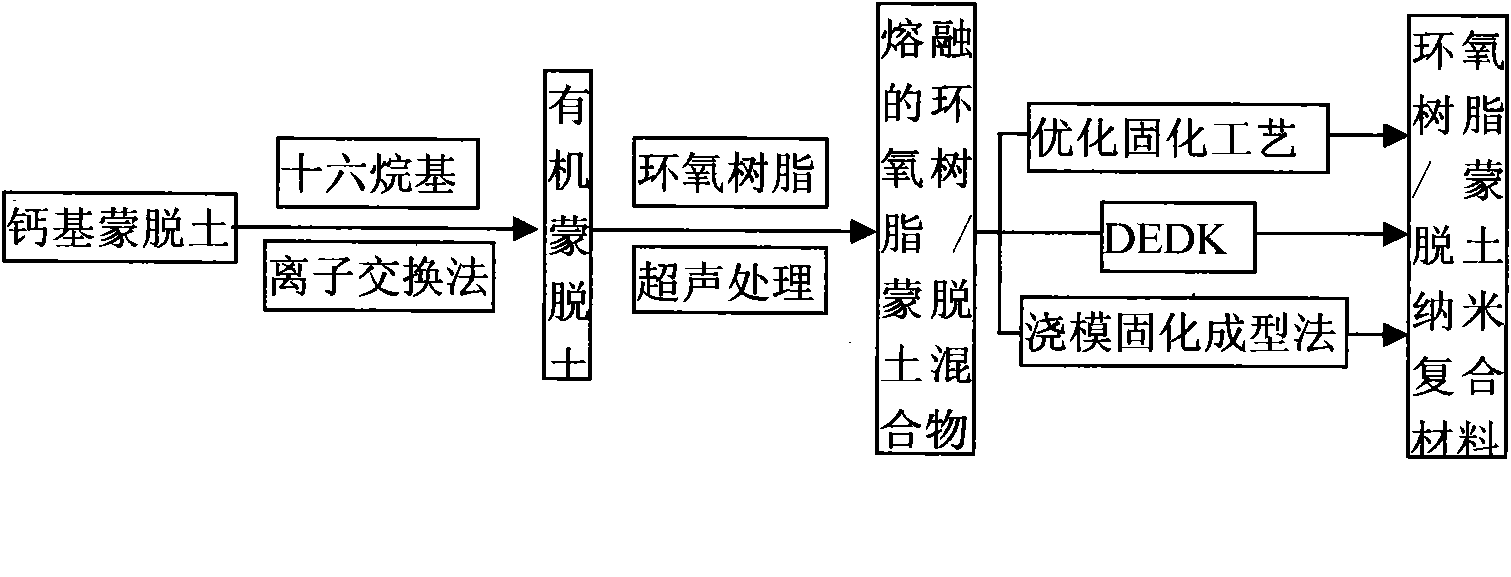

[0011] (1) Preparation of organic montmorillonite.

[0012] Add 250mL of distilled water, 250mL of 95% ethanol, and 0.02mol of cetyltrimethylammonium bromide into a 1000mL three-necked flask, and when stirring to raise the temperature to 80°C, add 10g of montmorillonite sieved through 300 mesh (according to every 100g of soil). Add 30-50g of organic amine), keep stirring and refluxing at 80°C for a certain period of time, then filter the obtained cloudy liquid under reduced pressure, then wash with 1:1 ethanol-distilled water, repeat several times until the separation liquid does not contain Br - (Add 0.1mol / LAgNO 3 No pale yellow precipitate), and finally, the isolate was vacuum-dried to constant weight at room temperature, ground into powder, and passed through a 300-mesh sieve to successfully prepare organic soil with ideal interlayer spacing.

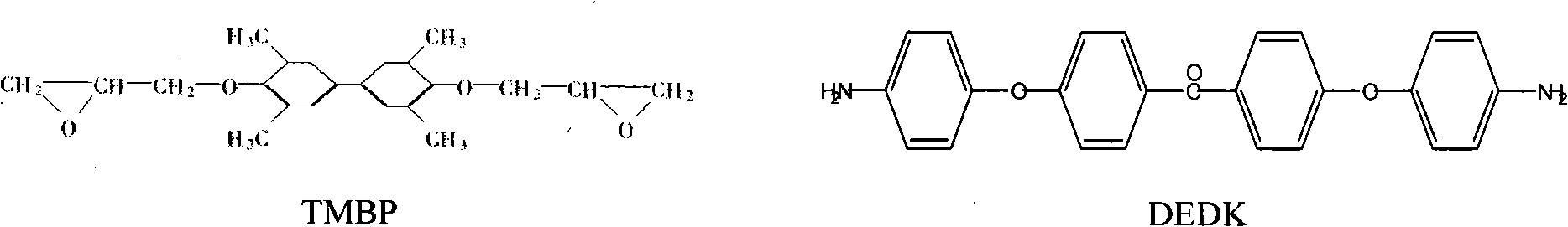

[0013] (2) Preparation of biphenyl-containing epoxy resin / montmorillonite nanocomposites

[0014] Add an appropriate amount of o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com