Method for preparing ZnO film by two-step deposition method

A deposition method and thin-film technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as environmental pollution, complex equipment, and film uniformity to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The ZnO thin film preparation process and steps in the present embodiment are as follows:

[0023] 1) Zn(CH 3 COO) 2 solution, pour it into the atomization tank of the ultrasonic nebulizer.

[0024] 2) Turn on the temperature controller of the heating furnace to raise the heating furnace to 400°C.

[0025] 3) Turn on the ultrasonic nebulizer and run the nebulizer to a stable working state.

[0026] 4) Adjust the flow rate of the carrier gas to keep the flow rate at 3L / min. And turn on the carrier gas and turn on the high voltage power supply.

[0027] 5) Grow for about 40 minutes, then turn off the high-voltage power supply and the atomizer, and let the prepared solution containing ZnO nanoparticles stand for 3 hours.

[0028] 6) Remove the supernatant, add 40mL deionized water, and disperse the precipitate with an ultrasonic cleaner

[0029] 7) Pour the decomposed solution into a centrifuge tube for the first separation.

[0030] 8) Take out the centrifuge tube,...

Embodiment 2

[0034] The growth and deposition process steps in this embodiment are completely the same as those in Embodiment 1 above, except that some process parameters are changed. Its different process parameters are: (1) Zn (CH3COO) The concentration of the solution is 0.05mol / L (2) The time for growing nanoparticles is 2 hours (3) The rotating speed of the spin coater is set to be at first the rotating speed of 400rpm Turn down for 30s, then turn down for 30s at 2000rpm. Finally, a ZnO thin film is obtained.

Embodiment 3

[0036] The growth and deposition process steps in this embodiment are completely the same as those in Embodiment 1 above, except that some process parameters are changed. Its different process parameters are: (1) Zn(CH 3 COO) 2 The concentration of the solution was 0.15mol / L (2) the time for growing nanoparticles was 1 hour (3) the rotation speed of the spin coater was set to first rotate at 500rpm for 30s, and then at 1000rpm for 60s. Finally, a ZnO thin film is obtained.

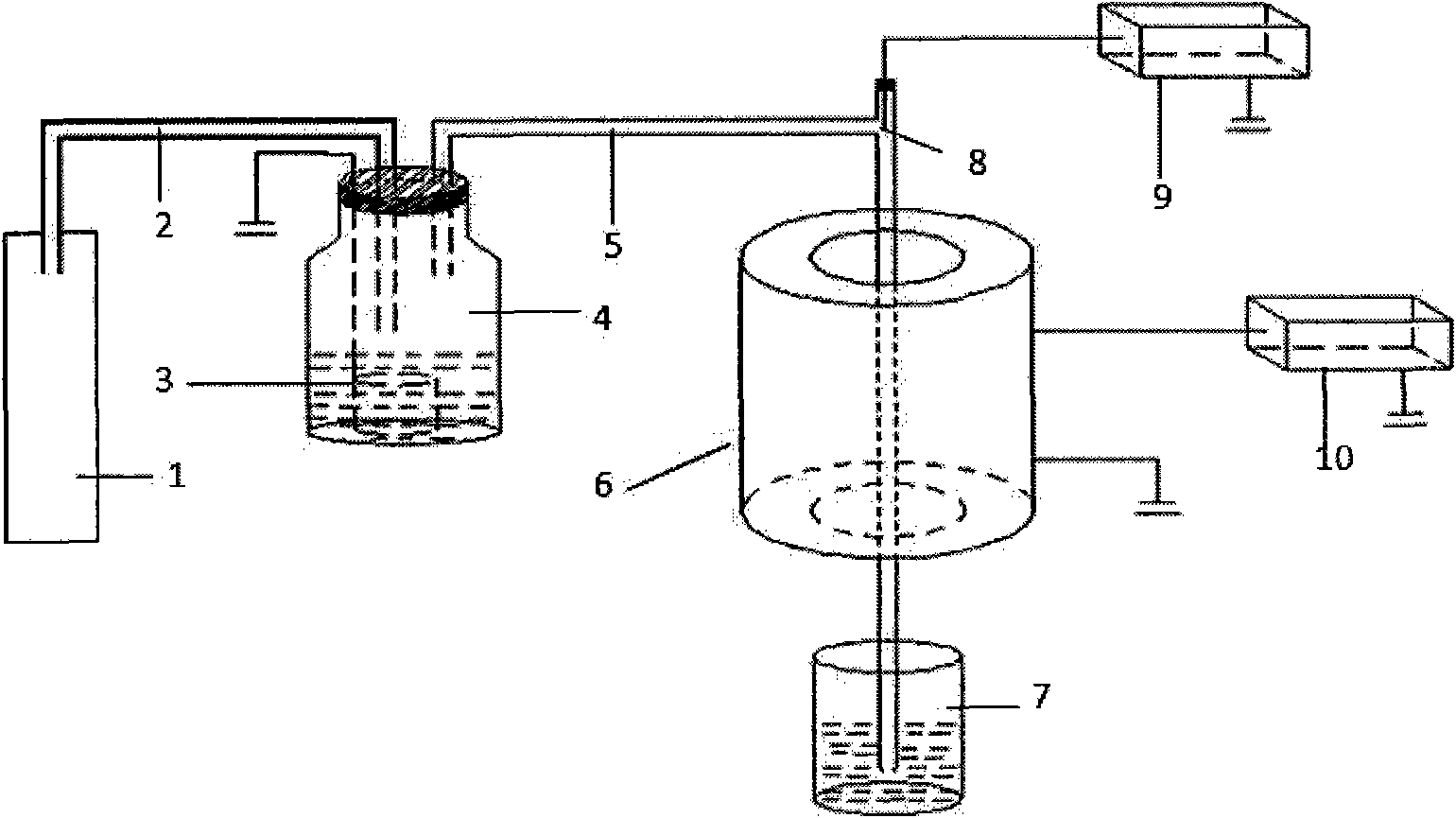

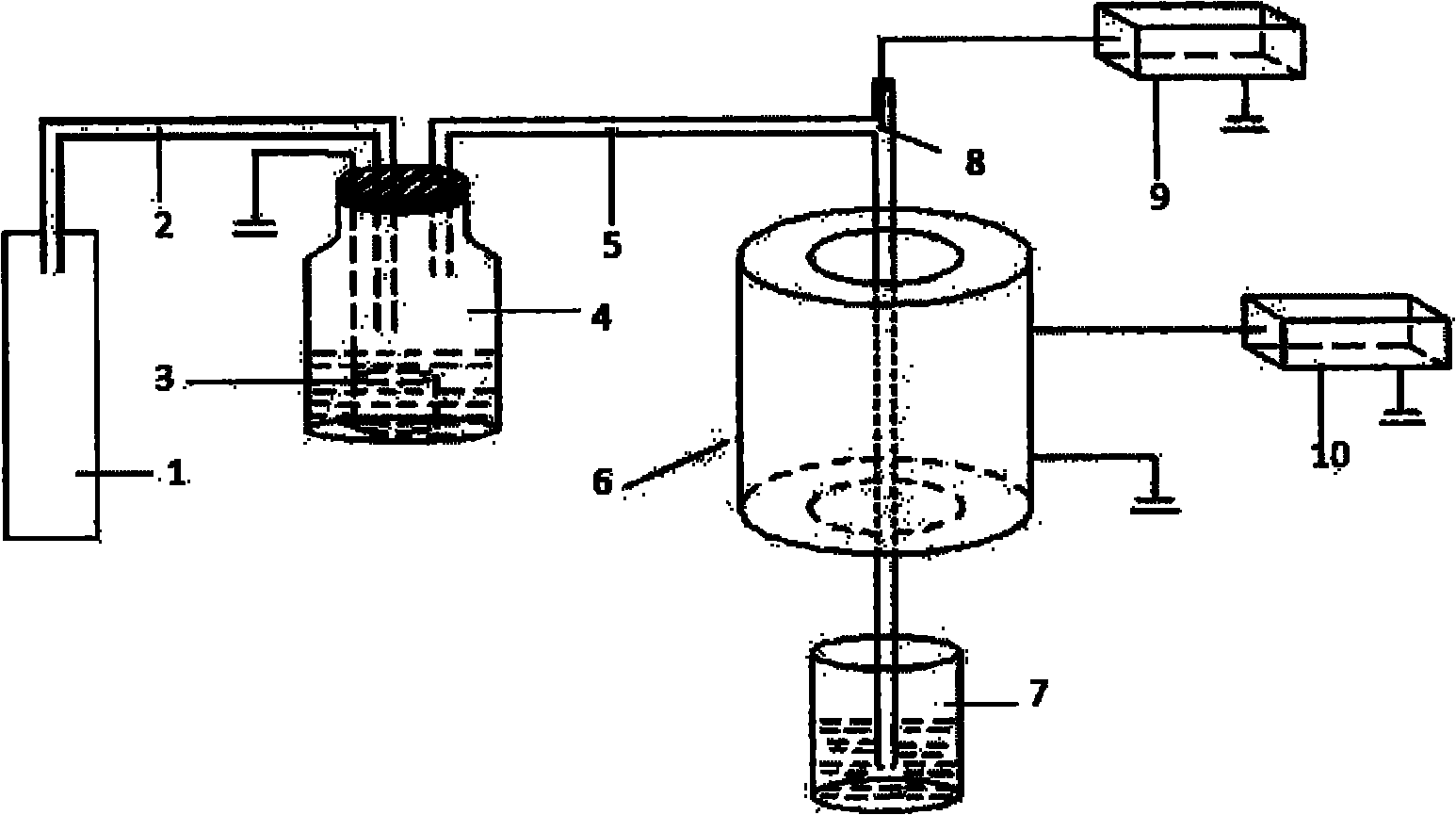

[0037] The preparation of ZnO nanoparticles in the examples adopts a special ultrasonic atomization heat method device.

[0038] see figure 1 .

[0039] The device includes: a nitrogen bottle 1, a rubber hose 2, an atomizer 3, an atomization tank 4, a quartz conduit 5, an electric heating furnace 6, a beaker 7, a charged nozzle 8, a high-pressure generator 9, and a temperature controller 10; An atomizer 3 is arranged at the bottom of the atomization tank 4 filled with the zinc acetate precursor soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com