Method for preparing proton exchange membrane fuel cell supported catalyst

A technology of supported catalysts and proton exchange membranes, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of catalyst particle growth and aggregation, difficulty in preparing high-load catalysts, etc., and achieve simplification Effects of post-treatment process, simple preparation method, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

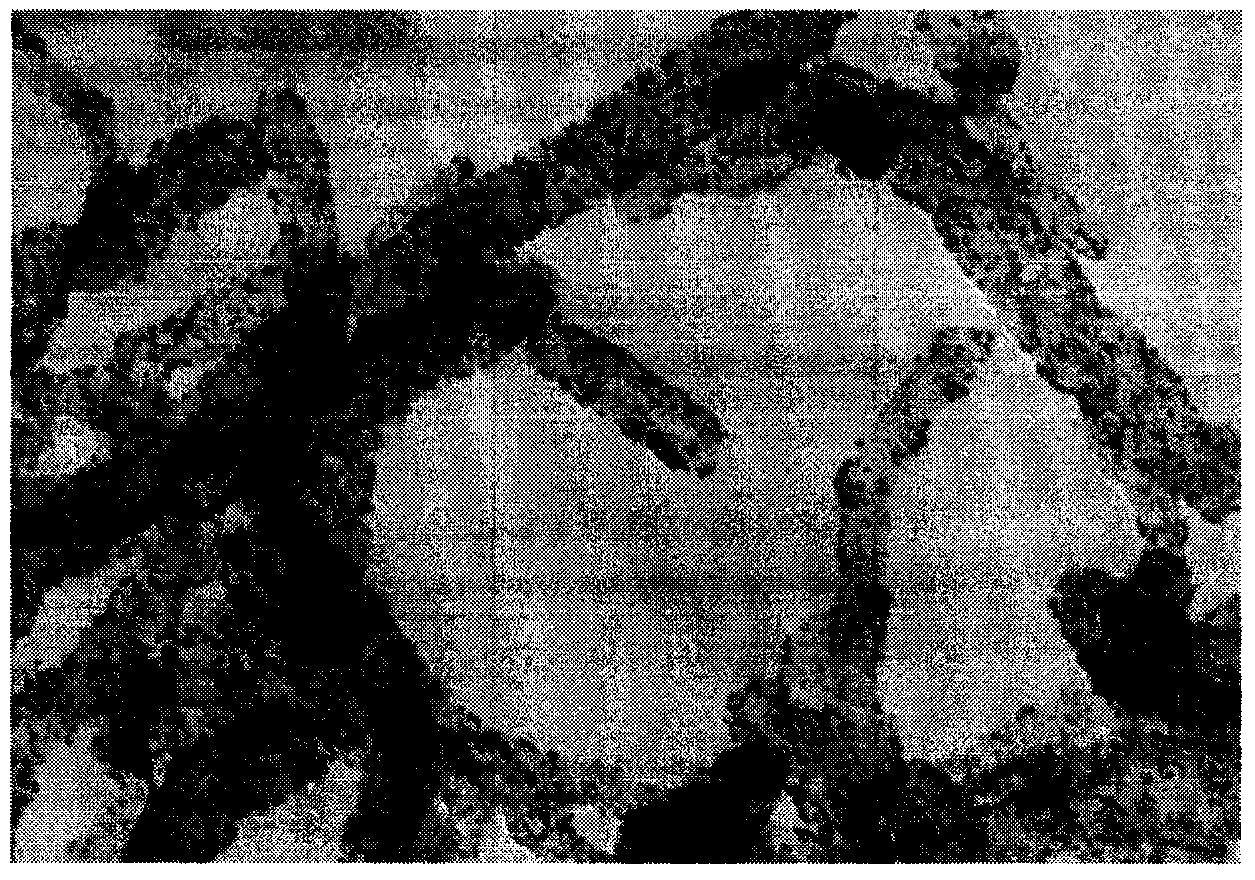

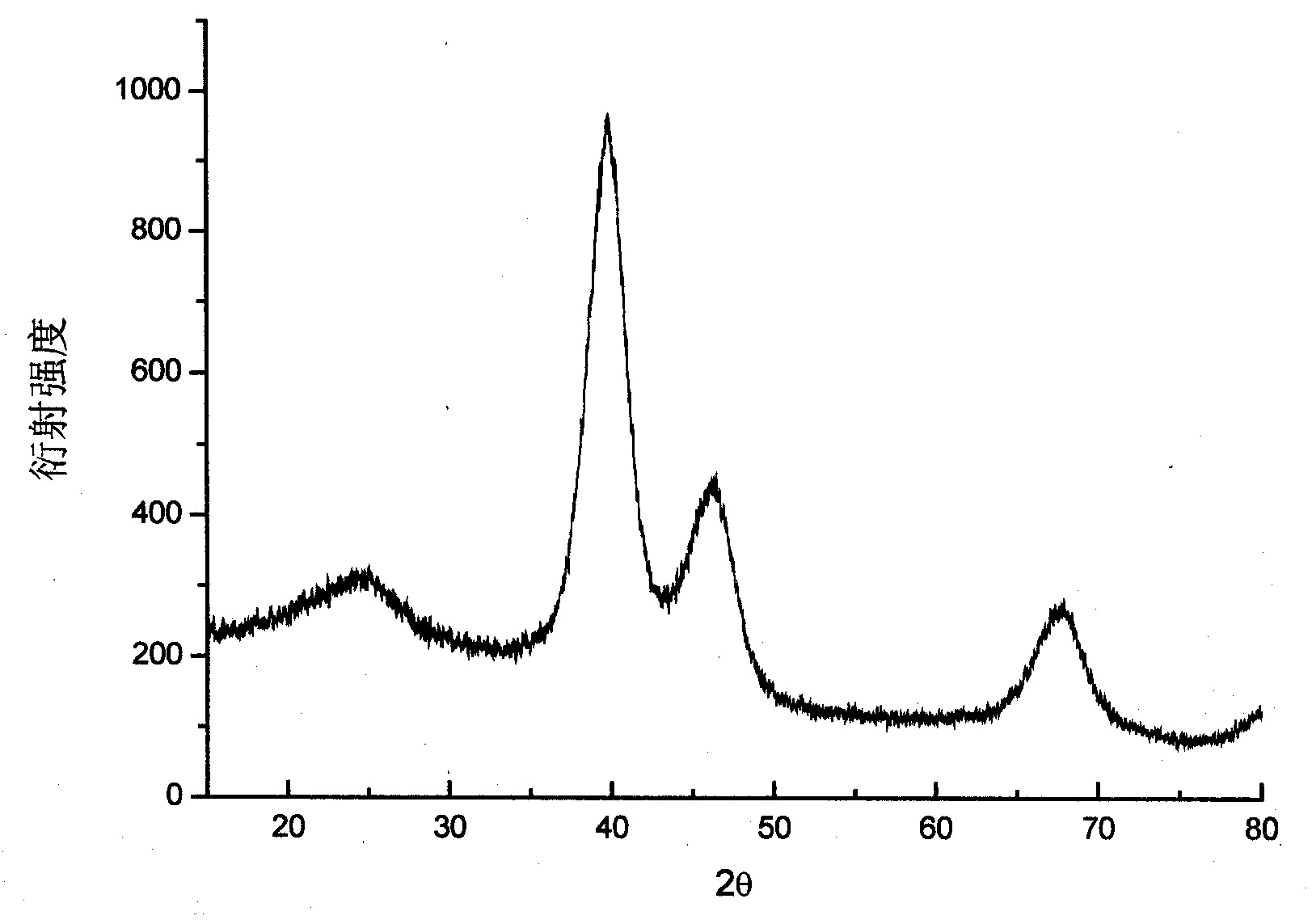

Embodiment 1

[0030] In the reactor, 0.54g H2 PtCl 6 ·6H 2 O was dissolved in a mixed solvent of 20mL ethylene glycol and 20mL water, and then 0.3g of multi-walled carbon nanotubes (MWNTs) was added thereto to fully disperse to form a suspension. This suspension was heated to 90°C, 5 mL of formaldehyde solution was added to the mixed system, and stirred at 90°C for 2 hours. The resulting mixture was filtered, and the filter cake was rinsed with deionized water until the filtrate was neutral. drying at H 2 with N 2 Under the protection of mixed gas, the obtained black solid powder was calcined at 200°C for 3 hours, and the heating rate was 20°C / min to obtain a Pt / C supported catalyst with a mass percentage of Pt of 40wt%. The volume percentage of hydrogen in the catalyst is 5%, and the average particle diameter of the Pt metal particles in the supported catalyst is 3.0nm.

Embodiment 2

[0032] In the reactor, 0.36g H 2 PtCl 6 ·6H 2 O and 0.21 g RuCl 3 ·6H 2 O was dissolved in a mixed solvent of 16mL ethylene glycol and 16mL water, and then 0.8g of activated carbon was added to it to fully disperse to form a suspension. The suspension was stirred and heated to 70° C., 3 mL of formaldehyde solution was added dropwise to the mixed system, and stirred at 70° C. for 3 hours. The resulting mixture was filtered, and the filter cake was rinsed with deionized water until the filtrate was neutral. drying at H 2 Under the protection of a mixed gas with Ar gas, the obtained black solid powder was calcined at 200° C. for 3 hours, and the heating rate was 5° C. / min. Can obtain the mass percent composition of metal be 20wt%, the PtRu / C supported catalyst that the atomic ratio of Pt: Ru is 1: 1; Wherein the volume percent composition of the hydrogen in the mixed gas is 20%, in the loaded catalyst The average particle size of the Pt metal particles is 2.5 nm.

[0033]...

Embodiment 3

[0035] In the reactor, 0.54g H 2 PtCl 6 ·6H 2 O and 0.26g Co(NO 3 ) 2 ·6H 2 O was dissolved in a mixed solvent of 10mL ethylene glycol and 40mL water, and then 0.75g carbon nanotubes were added thereto to fully disperse to form a suspension. The suspension was heated to 90°C, 0.5mL of 0.1g / mL sodium borohydride aqueous solution was added to the mixed system, and then 5mL of formaldehyde solution was added, and stirred at 90°C for 2 hours. The resulting mixture was filtered, and the filter cake was rinsed with deionized water until the filtrate was neutral. drying at H 2 with N 2 Under the protection of mixed gas, the obtained black solid powder was calcined at 200°C for 3 hours, and the heating rate was 10°C / min, so that the mass percentage of Pt was 20wt%, and the mass percentage of Co was 5wt%. PtCo / C supported catalyst; wherein the volume percentage of hydrogen in the mixed gas is 5%, and the average particle diameter of the PtCo alloy metal particles in the support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com