High-conversion rate silicon crystal and thin film compound type unijunction PIN (Positive Intrinsic-Negative) solar battery and manufacturing method thereof

A solar cell, high conversion rate technology, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

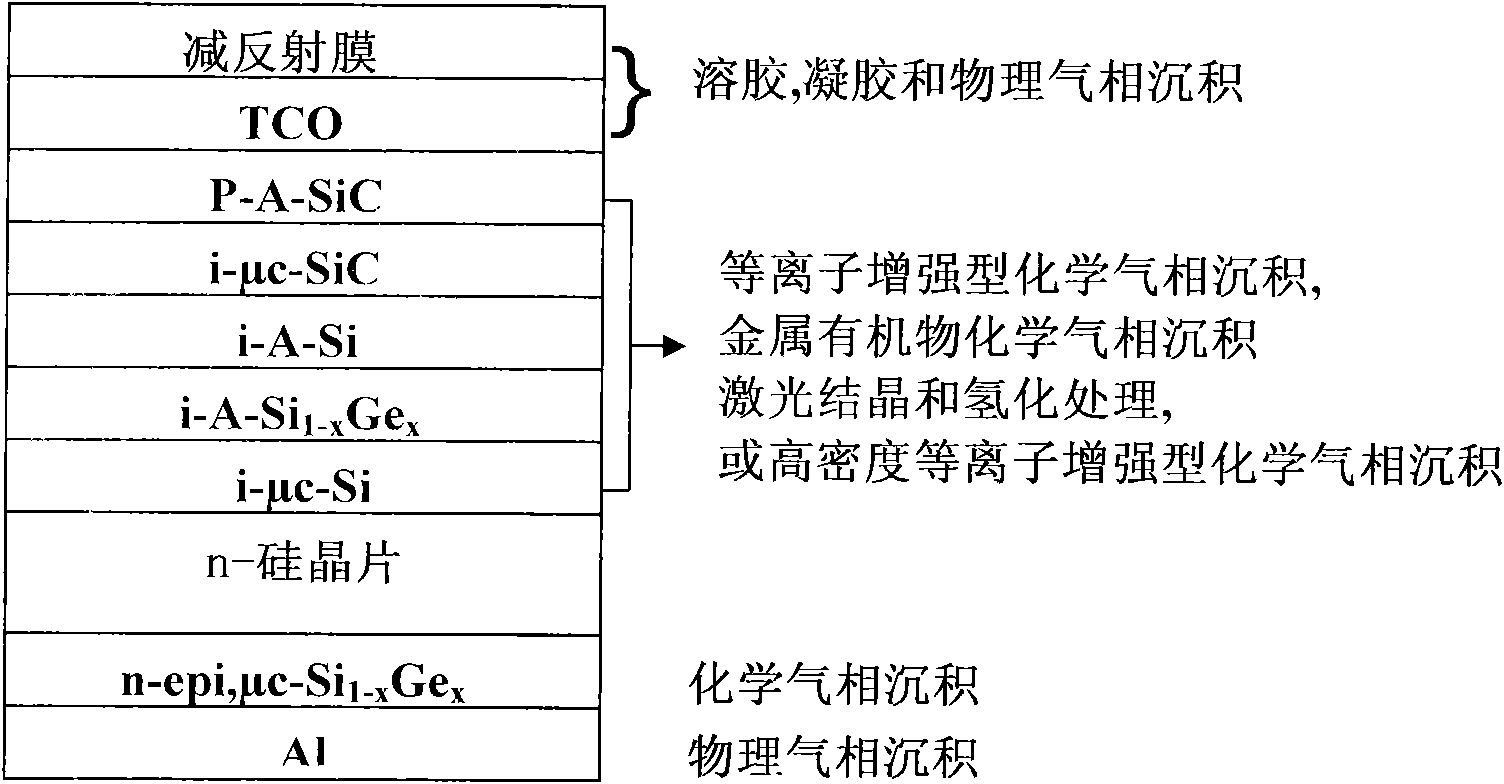

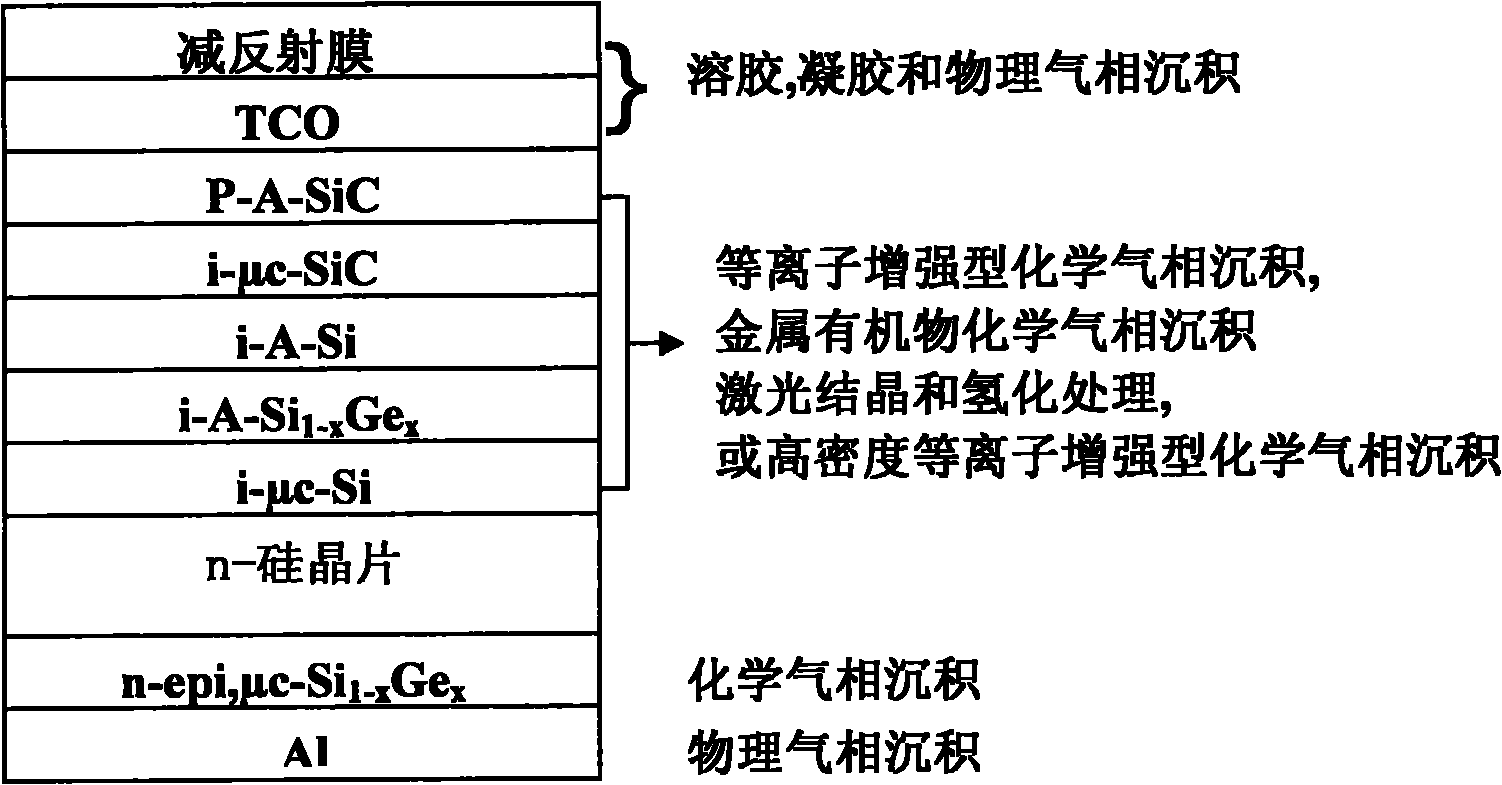

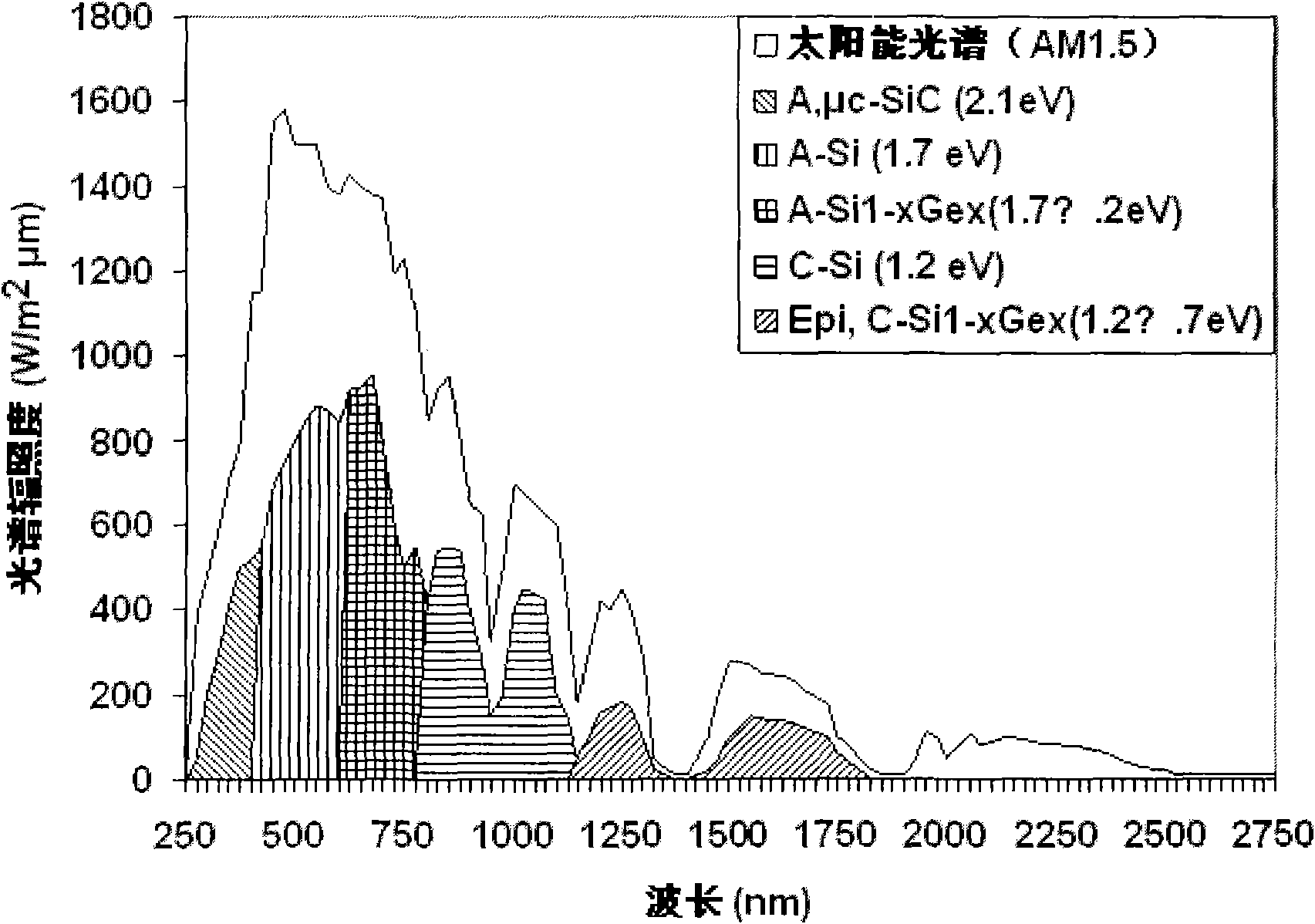

[0060] Example 1: A silicon crystal and thin film compound single-junction PIN solar cell single-junction six-layer pin structure thin-film solar cell, the structure is:

[0061] Bottom electrode / n-type gradient μc or epi Si 1-x Ge x / n-type silicon wafer / i-μc-Si / i-A-Si 1-x Ge x / i-A-Si / i-μc-SiC / p-A-SiC / TCO / anti-reflection coating.

Embodiment 2

[0062] Embodiment 2: preparation method

[0063] a. High-conversion silicon crystal and thin-film composite single-junction PIN solar cells Single-junction six-layer pin structure thin-film solar cells, the structure is: bottom electrode / n-type gradient g μc or epi Si 1-x Ge x / n-type silicon wafer / i-μc-Si / i-A-Si 1-x Ge x / i-A-Si / i-μc-SiC / p-A-SiC / TCO / anti-reflection coating.

[0064] b. Preparation process:

[0065] 1. Chemical and mechanical (CMP) double-sided polishing of n-type silicon wafers (monocrystalline or polycrystalline); then,

[0066] 2. Cleaning of n-type silicon wafers (single crystal silicon wafers or polycrystalline silicon wafers);

[0067] 3. Use PECVD to form silicon-rich silicon oxide or TCO intermediate reflection layer film;

[0068] 4. On the front side of n-type silicon wafers (single crystal silicon wafers and polycrystalline silicon wafers), deposit phosphorus (P) doped n-type Ge by CVD method, and n-type gradient μc or epi Si 1-x Ge x Thin f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Membrane thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap