Preparation method of genipin

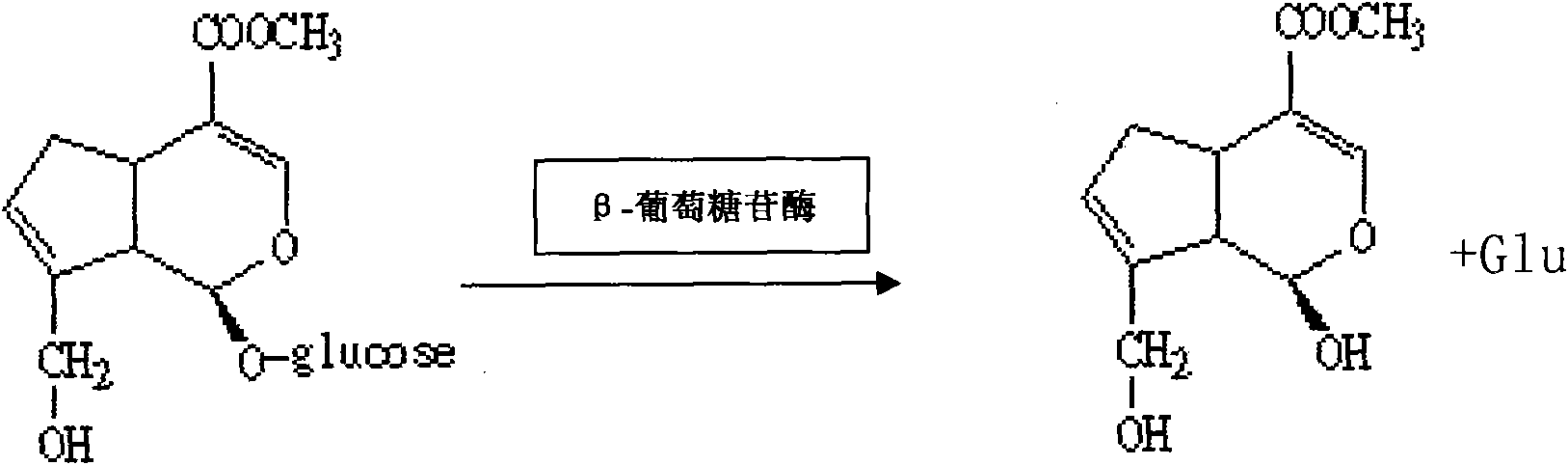

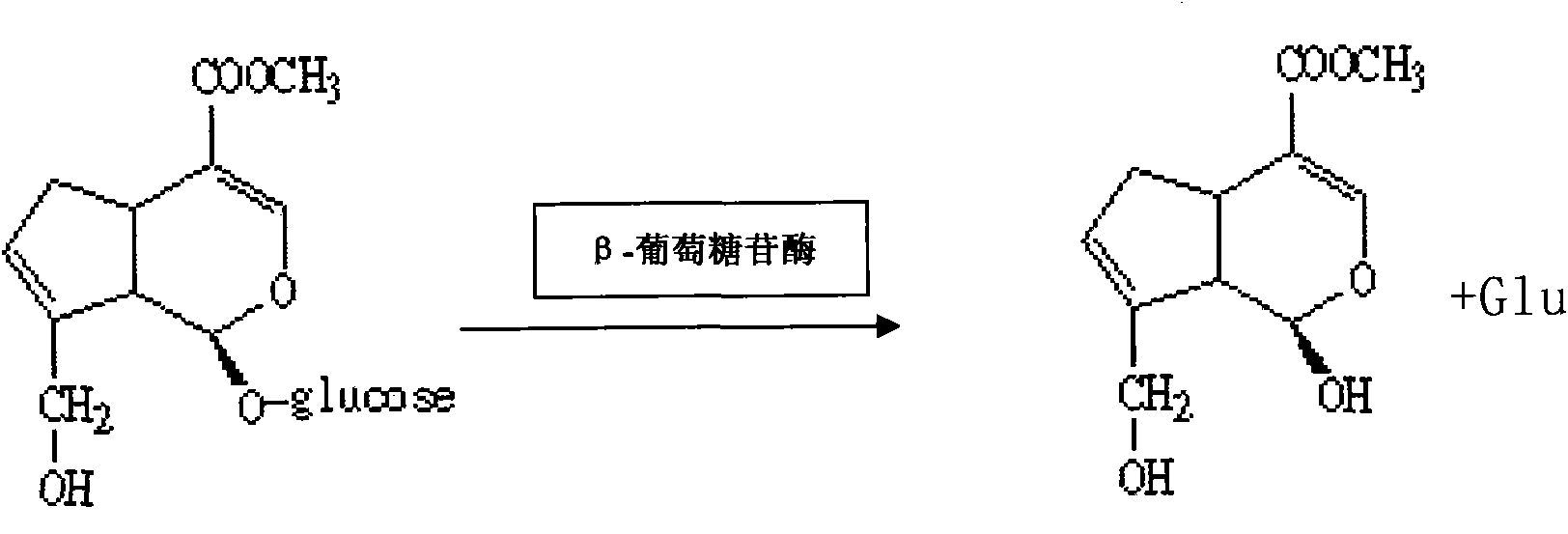

A technology of genipin and preparation process, applied in microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., can solve the problem that genipin is expensive and reduces the yield of genipin , the environment is easy to cause pollution and other problems, to achieve the effect of low cost, improve yield and overcome high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Ferment the enzyme-producing Aspergillus niger strain for 96 hours, take out the fermented liquid together with mycelium, and concentrate it with a hollow fiber ultrafilter with a molecular weight of 6000 to about one-third of the original volume, and add the final The gelatin with a concentration of 1% and the glutaraldehyde with a final concentration of 0.25% were cross-linked, the cross-linking time was 1 hour, and the cross-linking temperature was 10°C;

[0037] (2) Embedding the cross-linked enzyme and mycelia liquid with sodium alginate, the concentration of sodium alginate being 3%;

[0038] (3) Add the embedded mixed solution dropwise to the calcium chloride solution for fixation, the concentration of calcium chloride is 3%, and prepare immobilized enzyme pellets;

[0039] (4) Place the prepared immobilized enzyme pellets at room temperature in 0.5% calcium chloride solution for hardening, and the hardening time is 2 hours;

[0040] (5) Filter the hardened ...

Embodiment 2

[0044] (1) Ferment the enzyme-producing Aspergillus Usami strain for 120 hours, take out the fermented liquid together with mycelia, concentrate it with a hollow fiber ultrafilter with a molecular weight of 30,000, and concentrate it to about one-fifth of the original volume, and add the final Concentration is 0.5% chitosan and final concentration is 0.5% glutaraldehyde to carry out cross-linking, cross-linking time is 2 hours, and cross-linking temperature is 20 ℃;

[0045] (2) Embedding the cross-linked enzyme and mycelia liquid with sodium alginate, the concentration of sodium alginate being 3%;

[0046] (3) Add the embedded mixed solution dropwise to the calcium chloride solution for fixation, the concentration of calcium chloride is 3%, and prepare immobilized enzyme pellets;

[0047] (4) Place the prepared immobilized enzyme beads at room temperature in 0.5% calcium chloride solution for hardening, and the hardening time is 3 hours;

[0048] (5) Filter the hardened immo...

Embodiment 3

[0052] (1) Ferment the enzyme-producing Rhizopus oryzae strain for 96 hours, take out the fermented liquid together with mycelia, add a final concentration of 2% gelatin and a final concentration of 1% glutaraldehyde for cross-linking, and the cross-linking time is 1 hour , the crosslinking temperature is 10°C;

[0053] (2) Embedding the cross-linked enzyme and mycelia liquid with sodium alginate, the concentration of sodium alginate being 3%;

[0054] (3) Add the embedded mixed solution dropwise to the calcium chloride solution for fixation, the concentration of calcium chloride is 4%, and prepare immobilized enzyme pellets;

[0055] (4) Place the prepared immobilized enzyme pellets at room temperature in 0.5% calcium chloride solution for hardening, and the hardening time is 2 hours;

[0056] (5) Filter the hardened immobilized enzyme and store it at 4°C for later use;

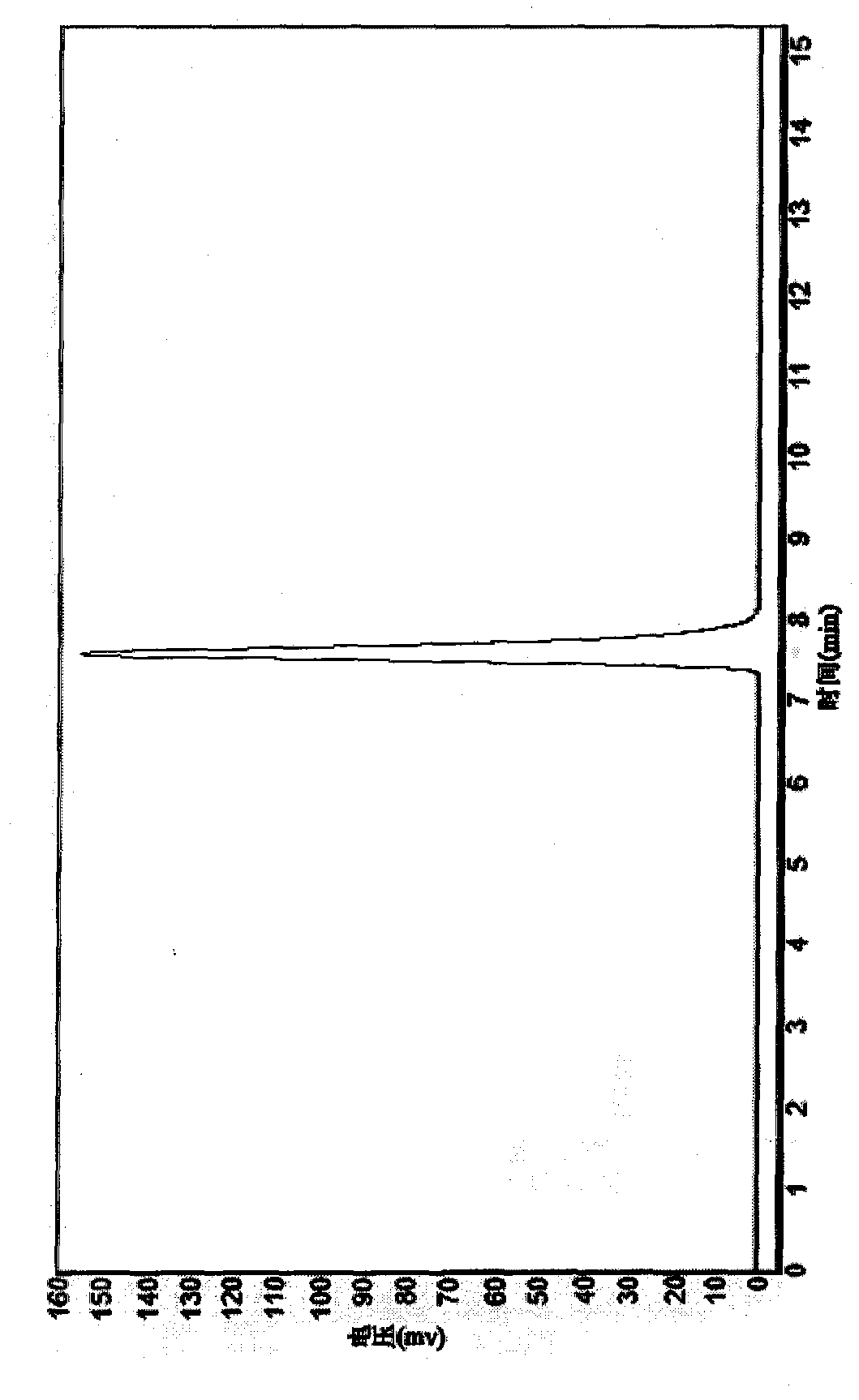

[0057] (6) Wet-pack the immobilized enzyme into a column, then prepare 2% geniposide solution, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com