Preparation method of genipin

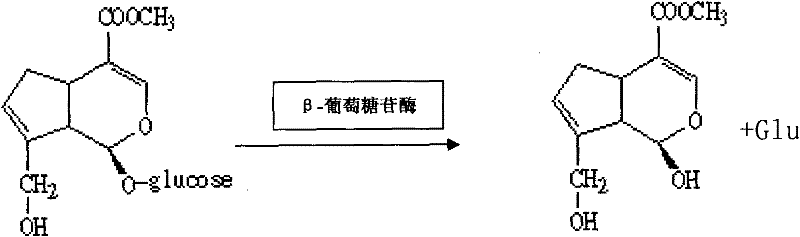

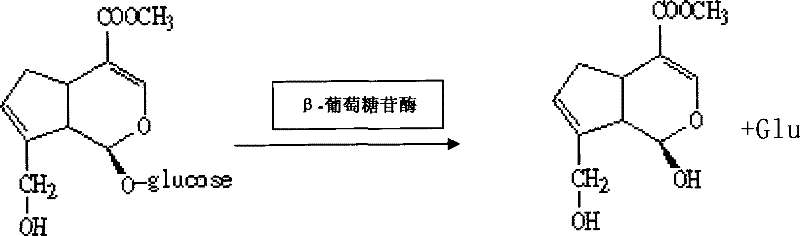

A technology of genipin and purity, applied in the direction of microorganism-based methods, biochemical equipment and methods, fixed on/in organic carriers, etc., can solve the problem of environmental pollution, reduce genipin yield, Beijing Nepin is expensive and other problems, to achieve the effect of low cost, increased yield, and long half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Ferment the enzyme-producing Aspergillus niger strain for 96 hours, take out the fermented liquid together with mycelium, and concentrate it with a hollow fiber ultrafilter with a molecular weight of 6000 to about one-third of the original volume, and add the final The gelatin with a concentration of 1% and the glutaraldehyde with a final concentration of 0.25% were cross-linked, the cross-linking time was 1 hour, and the cross-linking temperature was 10°C;

[0037] (2) Embedding the cross-linked enzyme and mycelia liquid with sodium alginate, the concentration of sodium alginate being 3%;

[0038] (3) Add the embedded mixed solution dropwise to the calcium chloride solution for fixation, the concentration of calcium chloride is 3%, and prepare immobilized enzyme pellets;

[0039] (4) Place the prepared immobilized enzyme pellets at room temperature in 0.5% calcium chloride solution for hardening, and the hardening time is 2 hours;

[0040] (5) Filter the hardened ...

Embodiment 2

[0044] (1) Ferment the enzyme-producing Aspergillus Usami strain for 120 hours, take out the fermented liquid together with mycelia, concentrate it with a hollow fiber ultrafilter with a molecular weight of 30,000, and concentrate it to about one-fifth of the original volume, and add the final Concentration is 0.5% chitosan and final concentration is 0.5% glutaraldehyde to carry out cross-linking, cross-linking time is 2 hours, and cross-linking temperature is 20 ℃;

[0045] (2) Embedding the cross-linked enzyme and mycelia liquid with sodium alginate, the concentration of sodium alginate being 3%;

[0046] (3) Add the embedded mixed solution dropwise to the calcium chloride solution for fixation, the concentration of calcium chloride is 3%, and prepare immobilized enzyme pellets;

[0047] (4) Place the prepared immobilized enzyme beads at room temperature in 0.5% calcium chloride solution for hardening, and the hardening time is 3 hours;

[0048] (5) Filter the hardened immo...

Embodiment 3

[0052] (1) Ferment the enzyme-producing Rhizopus oryzae strain for 96 hours, take out the fermented liquid together with mycelia, add a final concentration of 2% gelatin and a final concentration of 1% glutaraldehyde for cross-linking, and the cross-linking time is 1 hour , the crosslinking temperature is 10°C;

[0053] (2) Embedding the cross-linked enzyme and mycelia liquid with sodium alginate, the concentration of sodium alginate being 3%;

[0054] (3) Add the embedded mixed solution dropwise to the calcium chloride solution for fixation, the concentration of calcium chloride is 4%, and prepare immobilized enzyme pellets;

[0055] (4) Place the prepared immobilized enzyme pellets at room temperature in 0.5% calcium chloride solution for hardening, and the hardening time is 2 hours;

[0056] (5) Filter the hardened immobilized enzyme and store it at 4°C for later use;

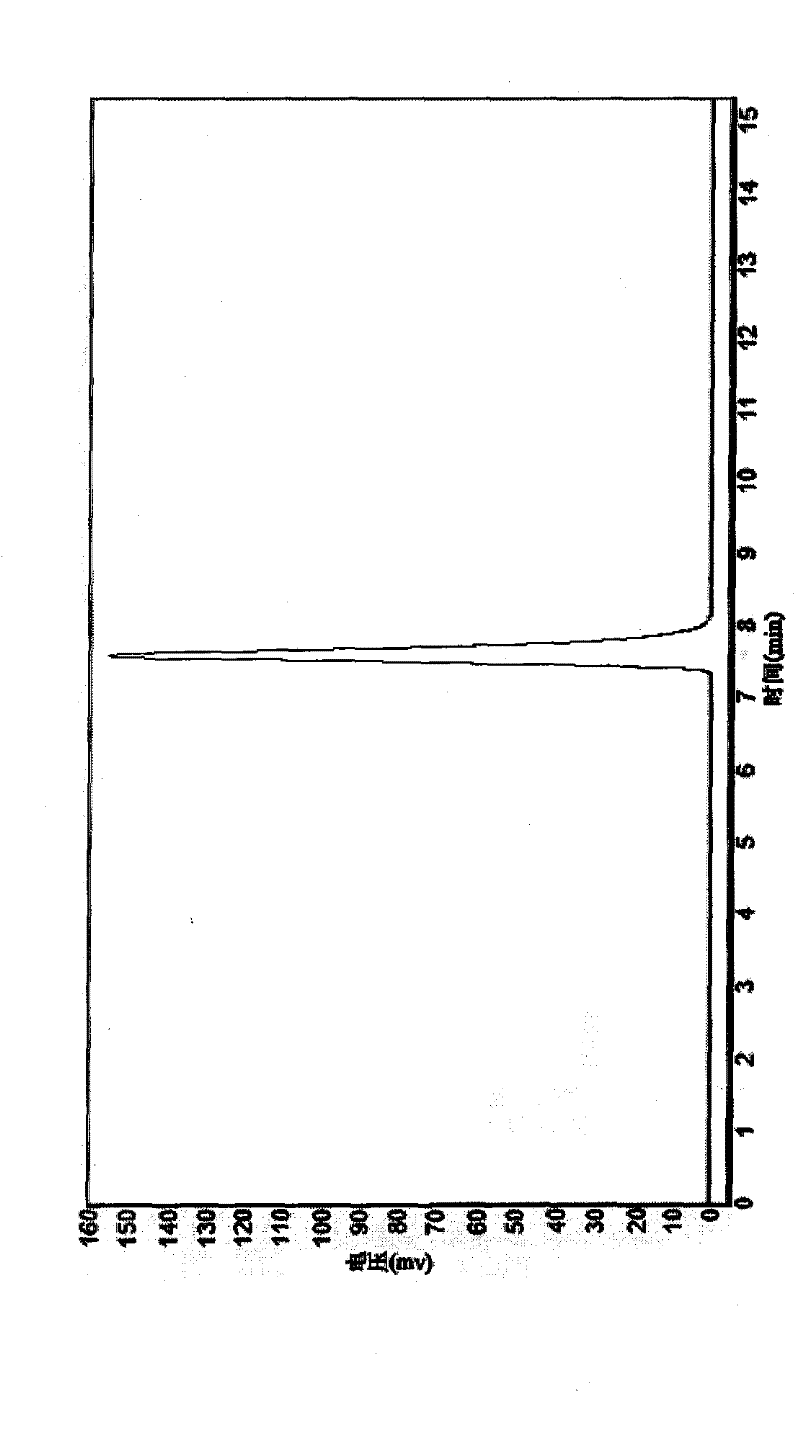

[0057] (6) Wet-pack the immobilized enzyme into a column, then prepare 2% geniposide solution, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com