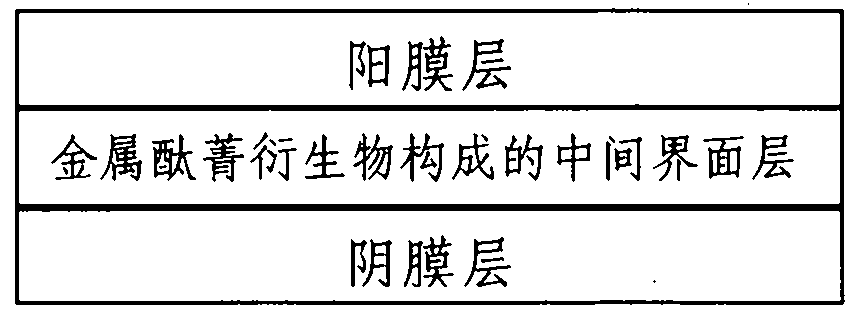

Bipolar membrane and preparation method thereof

A bipolar membrane and membrane layer technology, applied in the direction of diaphragm, electrolysis process, electrolysis components, etc., can solve the problems of poor ion permeability, high membrane impedance, low water dissociation efficiency, etc., and achieve high working current density and low membrane impedance , The effect of high water dissociation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

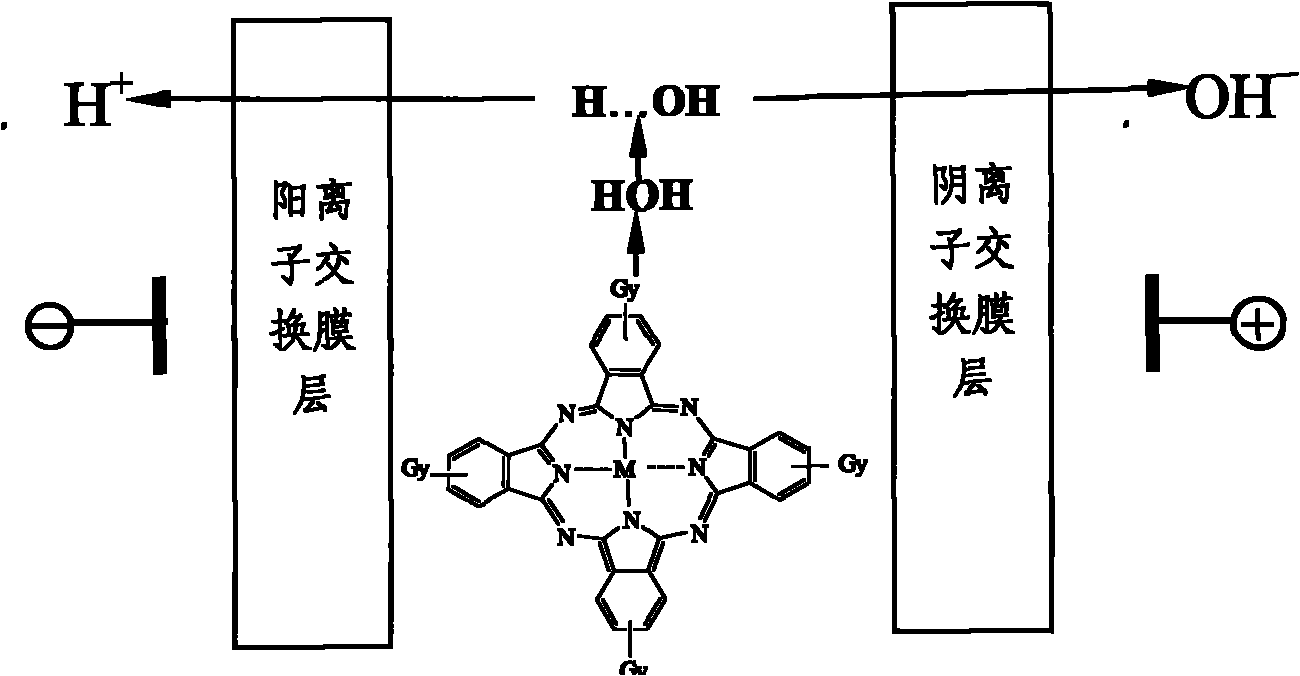

[0022] Preparation of Tetracarboxycobalt Phthalocyanine (CoPc(COOH) by Casting Method 4 ) is the bipolar membrane of the intermediate layer, and the concrete steps are as follows:

[0023] a. Preparation of positive film layer

[0024] Weigh 4g carboxymethylcellulose (CMC), 1g polyvinyl alcohol (PVA), 0.3g copper chloride to prepare 100mL CuCl 2 - Stir the PVA-CMC mixed solution evenly, degas under reduced pressure to obtain a viscous film solution, cast it on a flat flat glass, and air-dry it at room temperature to obtain a Cu-PVA-CMC positive film layer.

[0025] B, the preparation of tetracarboxycobalt phthalocyanine intermediate layer

[0026] Weigh 0.05g tetracarboxycobalt phthalocyanine, dissolve it with 20mL THF and pour it on the prepared Cu-PVA-CMC positive film layer, and air-dry it at room temperature, that is, attach a layer of Tetracarboxylate on the Cu-PVA-CMC positive film layer. Carboxylic cobalt phthalocyanine.

[0027] c. Preparation of anion fluid

[00...

Embodiment 2

[0035] Tetracarboxyzinc phthalocyanine (ZnPc(COOH) 4 ) is the bipolar membrane of the intermediate layer, and the concrete steps are as follows:

[0036] a. The preparation of positive film layer is the same as casting method (a).

[0037] b. The preparation of the negative film layer is the same as the casting method (c). After modification of polyacrylamide, dialysis and purification for 24 hours, mPAM negative membrane layer gel can be obtained.

[0038] c. Preparation of the intermediate interface layer

[0039] Weigh 0.05g tetracarboxyzinc phthalocyanine, dissolve it with 20mL THF and pour it on the prepared Cu-PVA-CMC positive film layer, and air-dry it at room temperature, that is, attach a layer of tetracarboxylate on the Cu-PVA-CMC positive film layer. Carboxylated Zinc Phthalocyanine.

[0040] d. Bipolar film with tetracarboxyzinc phthalocyanine as the intermediate layer (Cu-PVA-CMC / ZnPc(COOH) 4 / mPAM bipolar membrane) preparation

[0041] The prepared mPAM neg...

Embodiment 3

[0046] Cobalt phthalocyanine octasulfonate (CoPc(SO 3 h) 8 ) is the preparation of the bipolar membrane of intermediate layer, concrete steps are as follows:

[0047] a, accurately take by weighing 3.9g sodium carboxymethylcellulose, be mixed with 3.0% (mass fraction) aqueous solution of sodium carboxymethylcellulose, accurately take by weighing 1g polyvinyl alcohol (PVA), dissolve with appropriate amount of distilled water, add to carboxymethylcellulose In the sodium methylcellulose aqueous solution, stir evenly, degas under reduced pressure, cast the viscous film solution on a clean and smooth petri dish, and dry it at room temperature to form a film. Soak the membrane in 9% (mass fraction) chromium chloride solution, wash it with distilled water after 30 minutes, and dry it naturally to obtain a Cr-PVA-CMC cation exchange membrane.

[0048] b. In addition, weigh a certain amount of cobalt phthalocyanine octasulfonate and dissolve it in 10 mL THF. cast on Cr-PVA-CMC catio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com