Crucible for growing crystalline silicon ingot and extracting silicon raw material of crystalline silicon ingot and preparation method and application thereof

A silicon raw material and crystalline silicon technology, applied in the field of solar-grade crystalline silicon growth and purification, can solve the problems of crucible or silicon ingot cracks and breakage, and achieve the effects of low cost, small surface friction coefficient and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

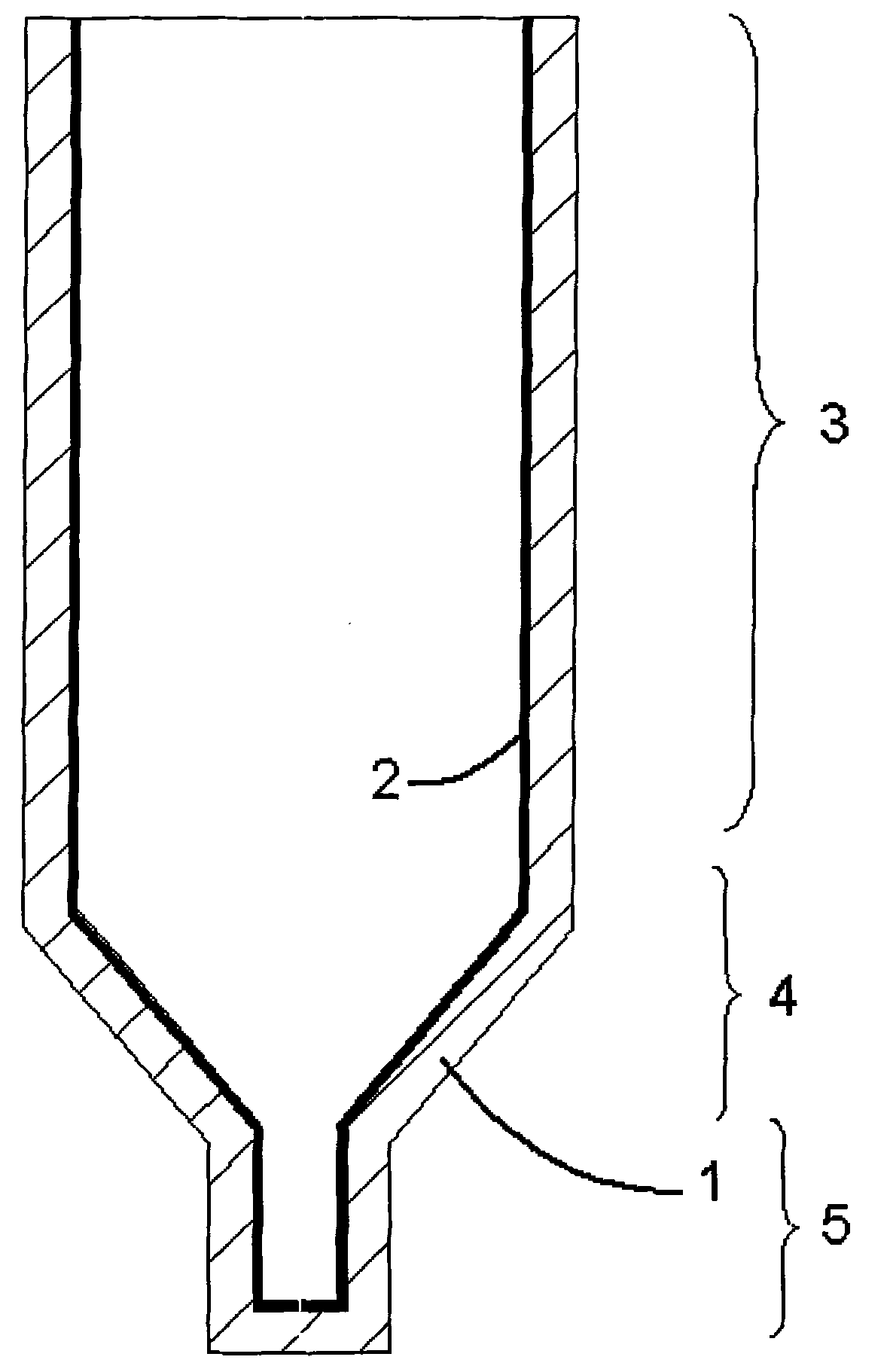

[0036] Such as figure 1 The shown crucible for growing solar-grade P-type silicon single crystal by directional solidification method includes a crucible outer shell 1 and a boron nitride inner liner 2 . The crucible shell 1 is made of graphite material, and the boron nitride lining 2 is attached to the inner wall surface of the crucible shell 1, and the thickness of the boron nitride lining 2 is 0.5mm.

[0037] The crucible as a whole is divided into three parts: a crucible main body 3 , a crucible bottom 4 , and a seed crystal sleeve 5 from top to bottom. During the production process, the silicon raw material is placed in the crucible main body 3, and the seed crystal is placed in the seed crystal casing 5. By controlling the temperature distribution, all the silicon raw material is melted, and at the same time, a part of the seed crystal close to the silicon raw material is melted. The remaining part of the unmelted seed crystal serves as the basis for seeding. By changi...

Embodiment 2

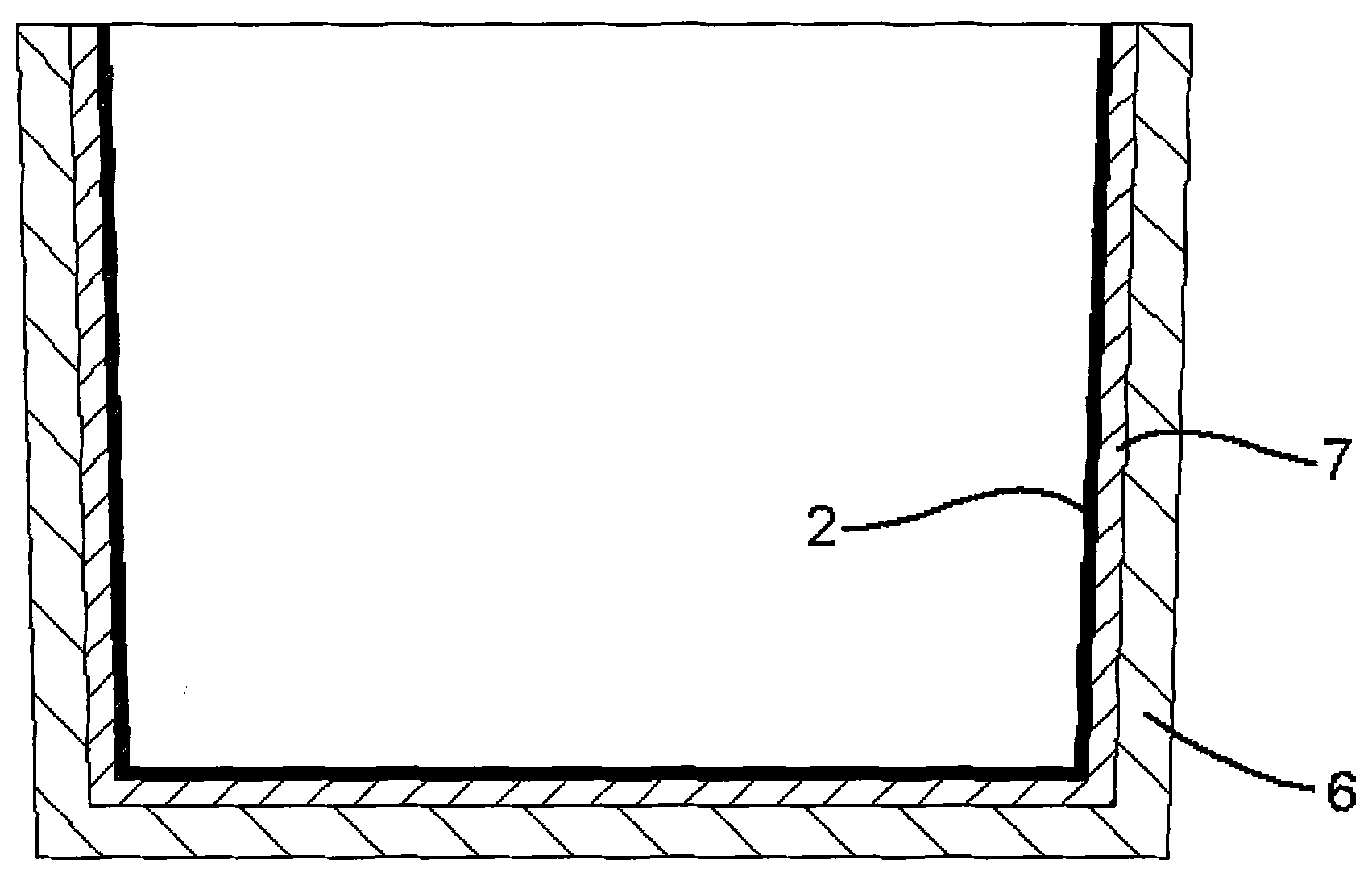

[0040] Such as figure 2 In the shown crucible for solar-grade silicon polycrystalline casting, the shell of the crucible is composed of double-layer materials, including a graphite shell 6 on the outside and a quartz shell 7 on the inside. The boron nitride lining 2 is coated on the inner surface of the quartz shell 7, and is coated by a spray coating method. The water-based boron nitride coating and deionized water are prepared into a slurry at a mass ratio of 1:10, and the It is sprayed on the inner surface of the quartz shell 7 at 0.3 MPa, baked and dried at 80° C., and formed on the inner surface of the quartz shell 7 with a thickness of 0.2 mm. The boron nitride coating is produced by GE Advanced Ceramics Corp., and its product model is EPC.

[0041] The crucible is used in a polycrystalline casting furnace to grow a large-sized solar-grade P-type silicon polycrystalline ingot.

[0042] The quality of boron nitride in the boron nitride lining 2 is 0.2% of the silicon r...

Embodiment 3

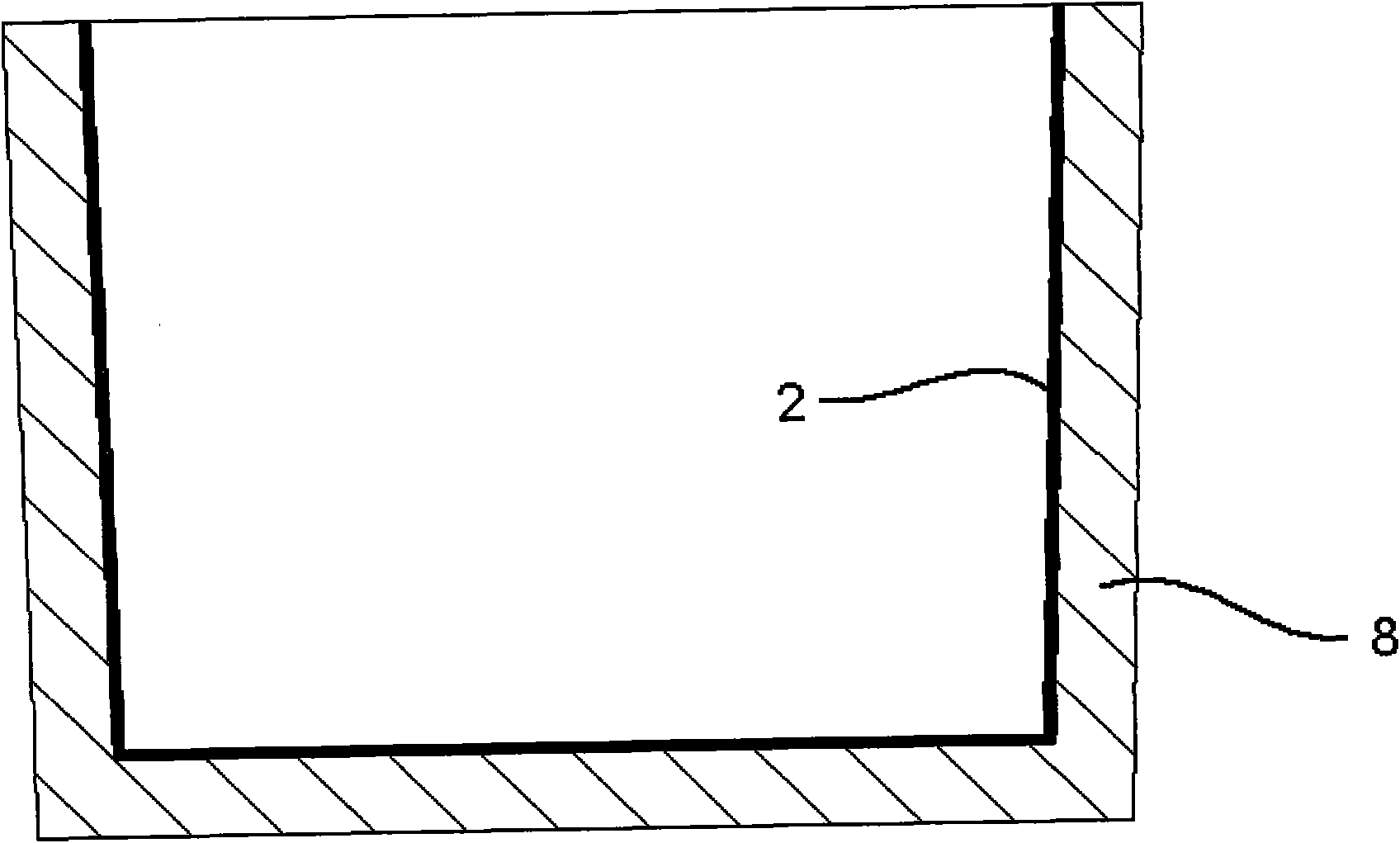

[0044] Such as image 3 The shown crucible for solar-grade silicon polycrystalline casting is composed of a crucible shell 8 and a boron nitride inner liner 2 . Similar to the second embodiment, the only difference is that the crucible shell 8 is made of one material, which is CFC (carbon-carbon composite) material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com