Method and device for preparing shrimp meat of euphausia superba

A technology for Antarctic krill and shrimp meat, applied in shrimp/lobster processing and other directions, can solve the problems of lowering the quality and sales price of finished products, large damage to the individual shape of shrimp meat, and unshelled Antarctic krill. Sufficient, high appearance, high meat yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

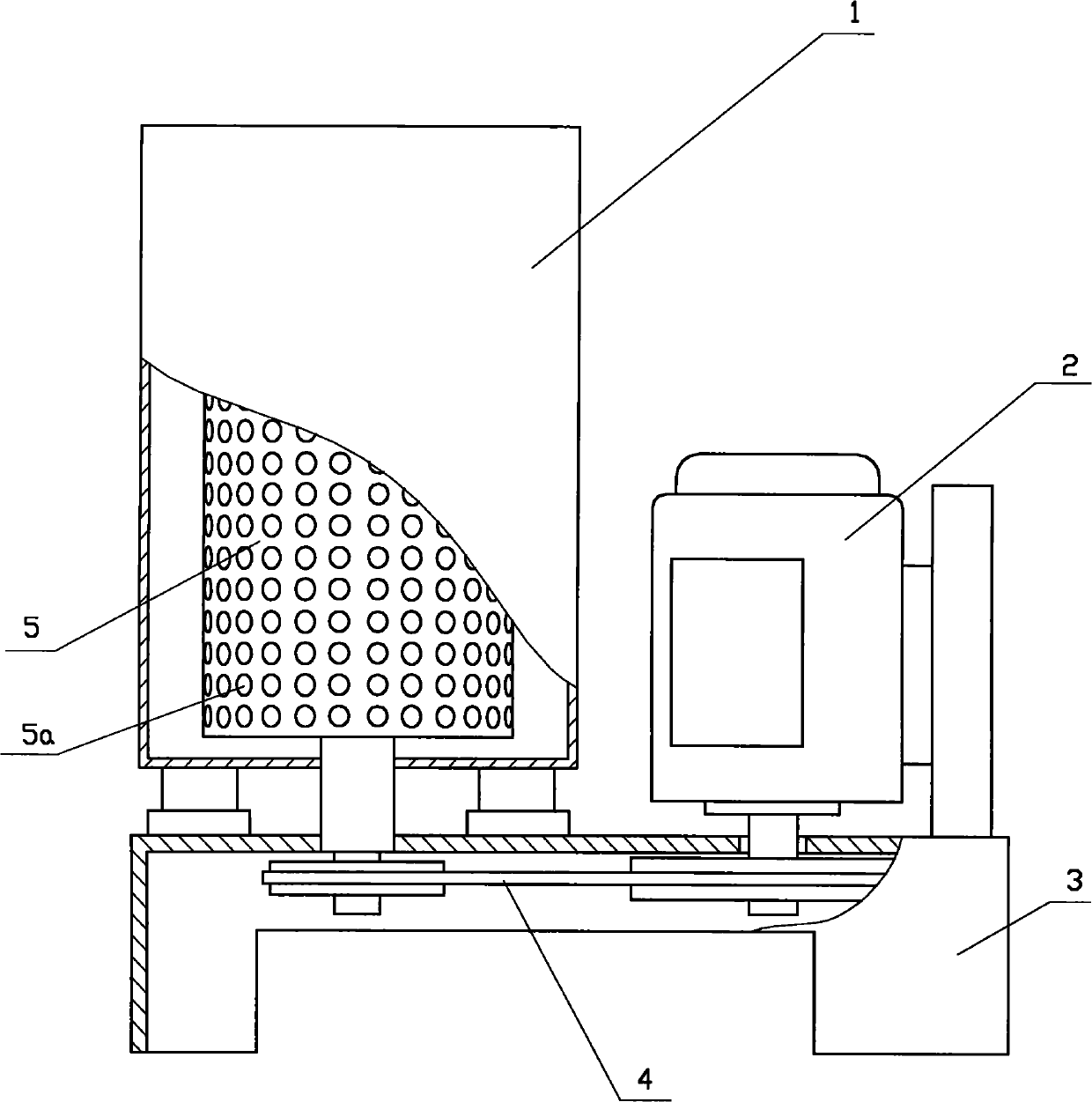

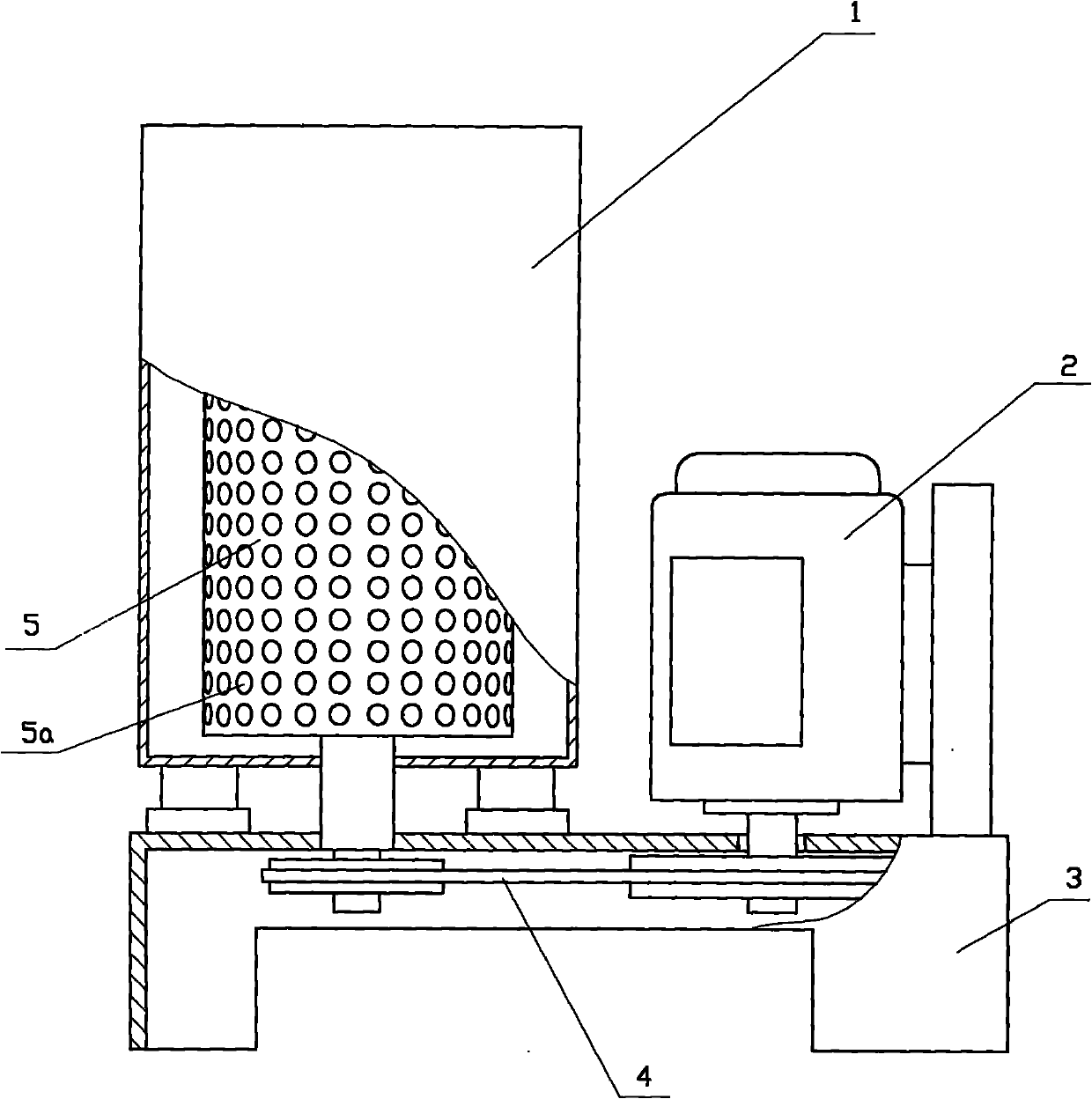

[0041] ① After Antarctic krill is caught, it is washed by seawater and transferred to a hollowed-out centrifugal cylinder within 1 hour. The hollowed hole diameter of the centrifugal cylinder is 1 mm, and the sieve hole spacing is 0.5 mm.

[0042] ②Put the centrifugal cylinder into a vertical centrifuge, set the diameter of the centrifugal cylinder to 40 cm, the rotational speed of the centrifugal cylinder to 6000 rpm, and the centrifugation time for 2 minutes.

[0043] ③After the treatment, collect the Antarctic krill shrimp meat, take out the centrifugal cylinder, and clean the shrimp shells.

[0044] Results: Under the technological conditions, the yield of Antarctic krill reached 17% (calculated as the ratio of the weight before harvesting).

Embodiment 2

[0046] ① After Antarctic krill is caught, it is washed by seawater and transferred to a hollow centrifugal cylinder within 1.5 hours. The hollow hole diameter of the centrifugal cylinder is 2 mm, and the sieve hole spacing is 1.5 mm.

[0047] ②Put the centrifugal cylinder into a vertical centrifuge, set the diameter of the centrifugal cylinder to 100 cm, the rotational speed of the centrifugal cylinder to 4000 rpm, and the centrifugation time to 4 minutes.

[0048] ③After the treatment, collect the Antarctic krill shrimp meat, take out the centrifugal cylinder, and clean the shrimp shells.

[0049] Results: Under the technological conditions, the meat yield of Antarctic krill reached 23% (calculated as the ratio of the weight before harvesting).

[0050] It is proved by the above examples that the present invention provides a device for mechanized meat harvesting of Antarctic krill under the conditions of rapidity, high yield, and striving to ensure the integrity of shrimp mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Centrifugal force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com