Self-assembly method for high-load inorganic nano particle hybridized organic membrane

An inorganic nanoparticle and nanoparticle technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

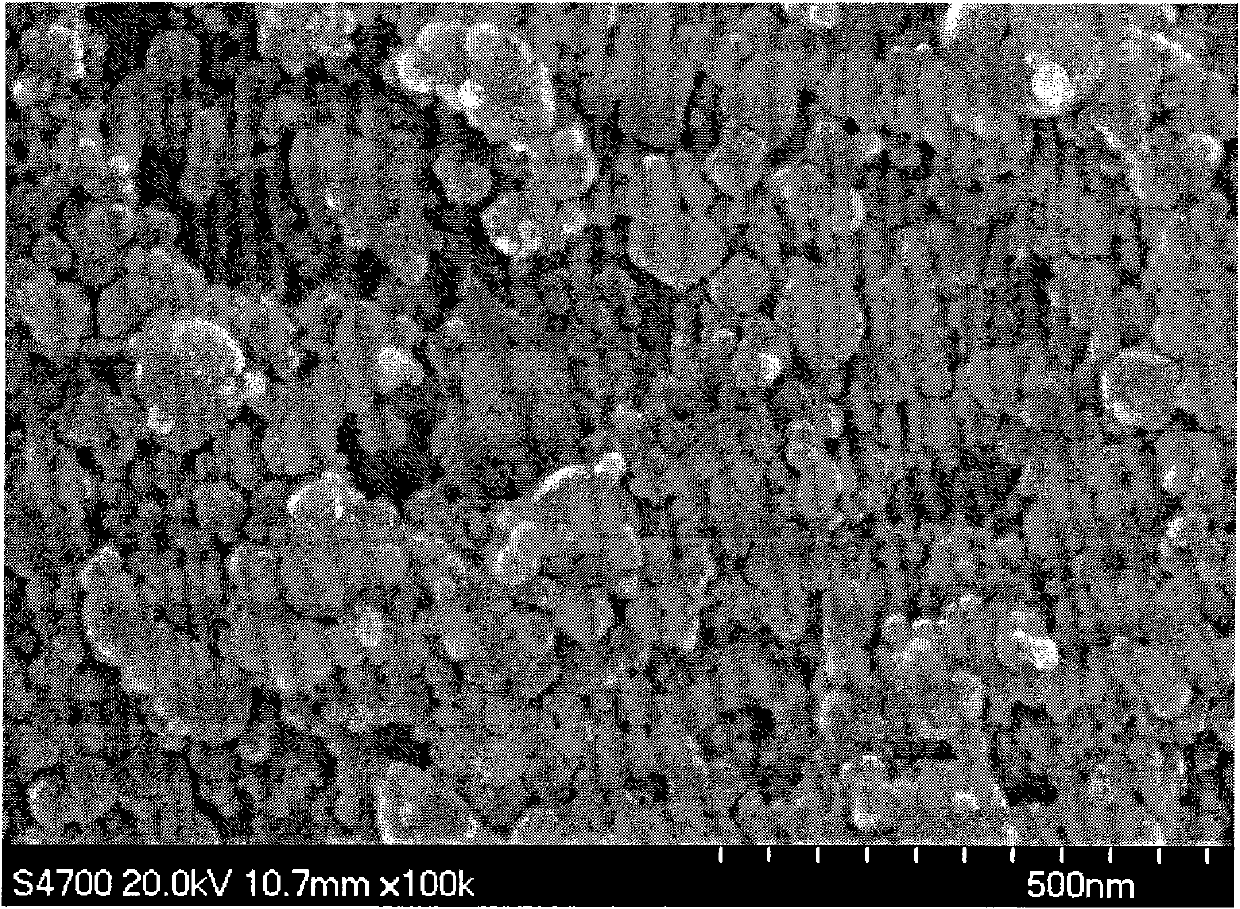

Embodiment 1

[0032] The substrate is quartz glass, the polycation material used is polydiallyldimethylammonium chloride (PDDA, molecular weight is 100000-200000), the polyanion is polystyrene sulfonate sodium (PSS, molecular weight is 70000), Nano zirconia particles (ZrO 2 , within 100nm, 5wt%), the solvents of polydiallyl dimethyl ammonium chloride and sodium polystyrene sulfonate are water.

[0033] Assembly conditions and methods:

[0034] (1) polydiallyl dimethyl ammonium chloride is made into 0.94wt% solution 500ml with deionized water, leaves standstill for degassing, adds nanometer zirconia particle 8ml, adjusts pH value to be 12; Use deionized water Sodium polystyrene sulfonate was made into 500ml of a 1.2wt% solution, allowed to stand for defoaming, and 8ml of nano-sized zirconia particles were added;

[0035] (2) Ultrasonic the polydiallyldimethylammonium chloride solution for 120 minutes to uniformly disperse the nanoparticles, centrifuge for 10 minutes, and replace the supern...

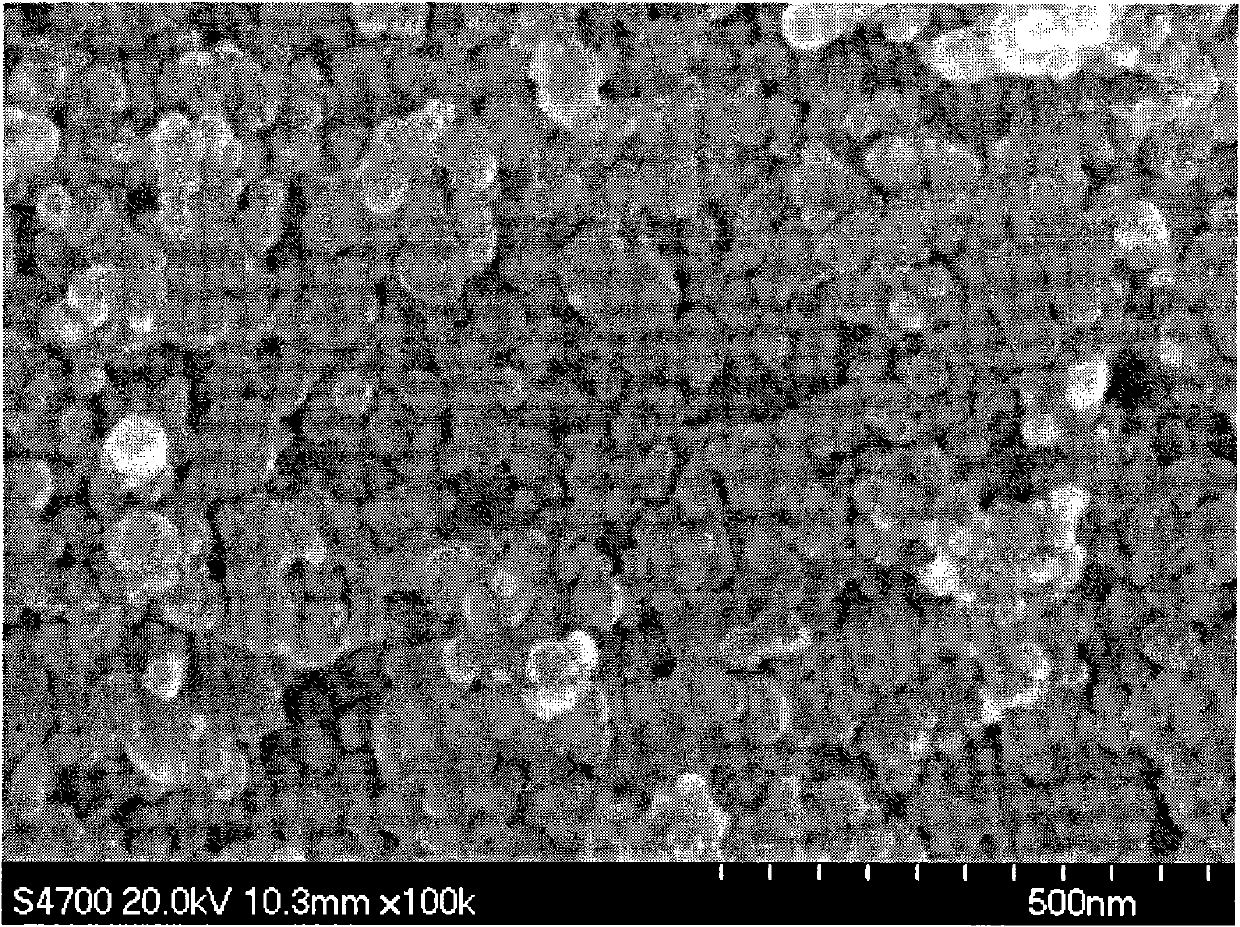

specific Embodiment 2

[0045] The substrate is quartz glass, the polycation material used is polyethyleneimine (PEI, with a molecular weight of 60,000), the polyanion is polyacrylic acid (PAA, with a molecular weight of 4 million), and nano-sized zirconia particles (ZrO 2 , within 100nm, 5wt%), the solvents of polyethyleneimine and polyacrylic acid are all water.

[0046] Assembly conditions and methods:

[0047] (1) polyethylenimine is made into 0.5wt% solution 500ml with deionized water, leaves standstill to defoam, adds nano zirconia particle solution 1ml; Polyacrylic acid is made into 0.05wt% solution 500ml with deionized water, Let it stand for defoaming, and add 1ml of nano-zirconia particle solution;

[0048] (2) Ultrasound the polyethyleneimine solution for 120 minutes to uniformly disperse the nanoparticles, centrifuge for 10 minutes, and replace the supernatant with an equal volume of deionized water after centrifugation; repeat 3 times to obtain polyethyleneimine nanoparticles Encapsula...

specific Embodiment 3

[0057] The base membrane is made of polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off and a membrane area of 28cm 2 , the polycation material used is polydiallyldimethylammonium chloride (PDDA, molecular weight is 100000~200000), the polyanion is polystyrene sulfonate sodium (PSS, molecular weight is 70000), nano zirconia particles (ZrO 2 , within 100nm, 5wt%), the solvents of polydiallyl dimethyl ammonium chloride and sodium polystyrene sulfonate are water.

[0058] Assembly conditions and methods:

[0059] (1) polydiallyl dimethyl ammonium chloride is made into 0.94wt% solution 500ml with deionized water, leaves standstill for defoaming, adds nanometer zirconia particle 8ml, adjusts pH to be 12; Use deionized water Sodium polystyrene sulfonate was made into 500ml of a 1.2wt% solution, allowed to stand for defoaming, and 8ml of nano-sized zirconia particles were added;

[0060] (2) Ultrasound the polydiallyldimethylammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com