Ion beam surface treatment equipment and method for suppressing secondary electron emission

A secondary electron emission and surface treatment technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of reducing the collector efficiency of traveling wave tubes, increasing high-frequency heat dissipation power, and reducing the efficiency of traveling wave tubes. Achieve the effect of low processing cost, secondary electron emission suppression, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

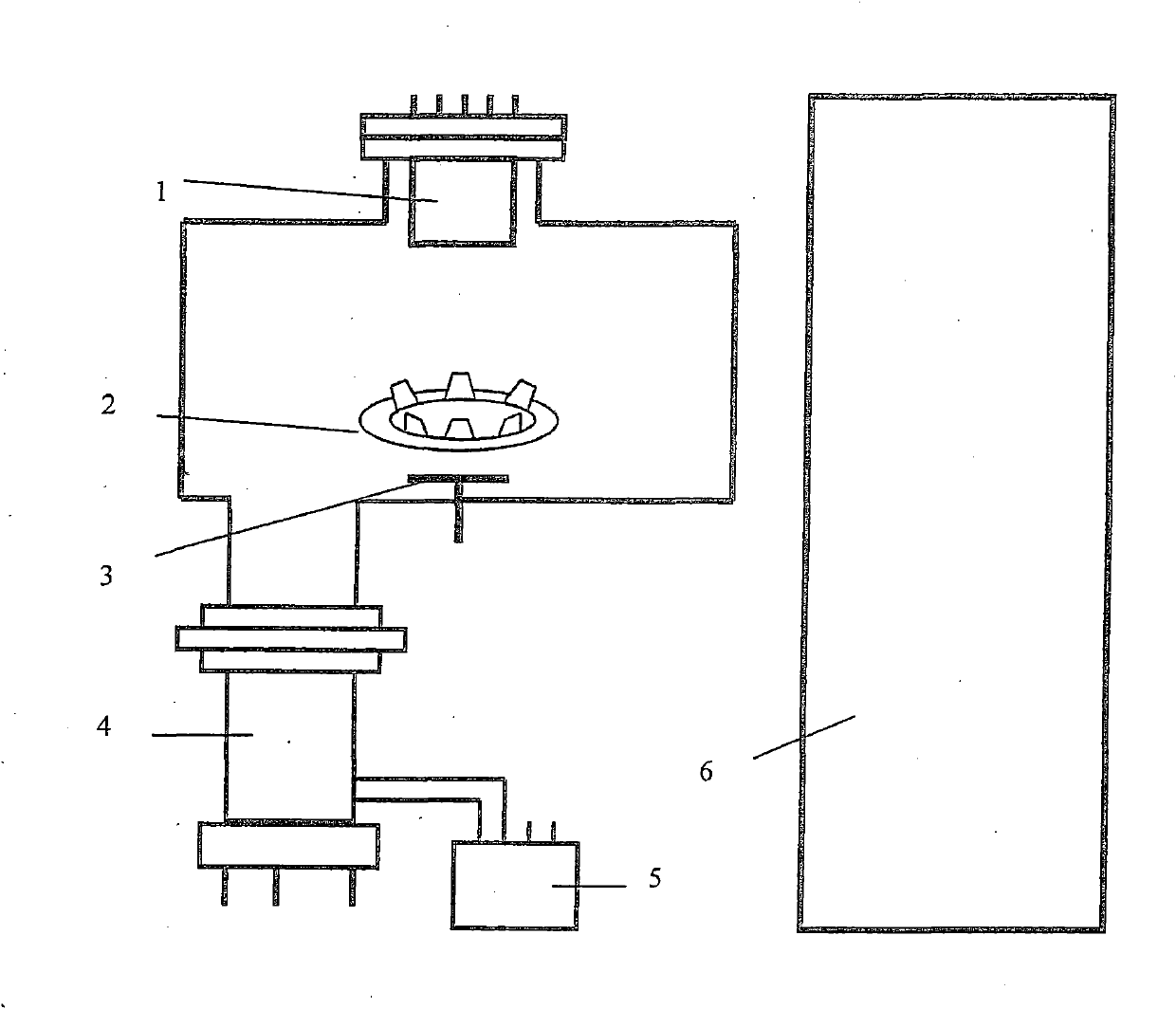

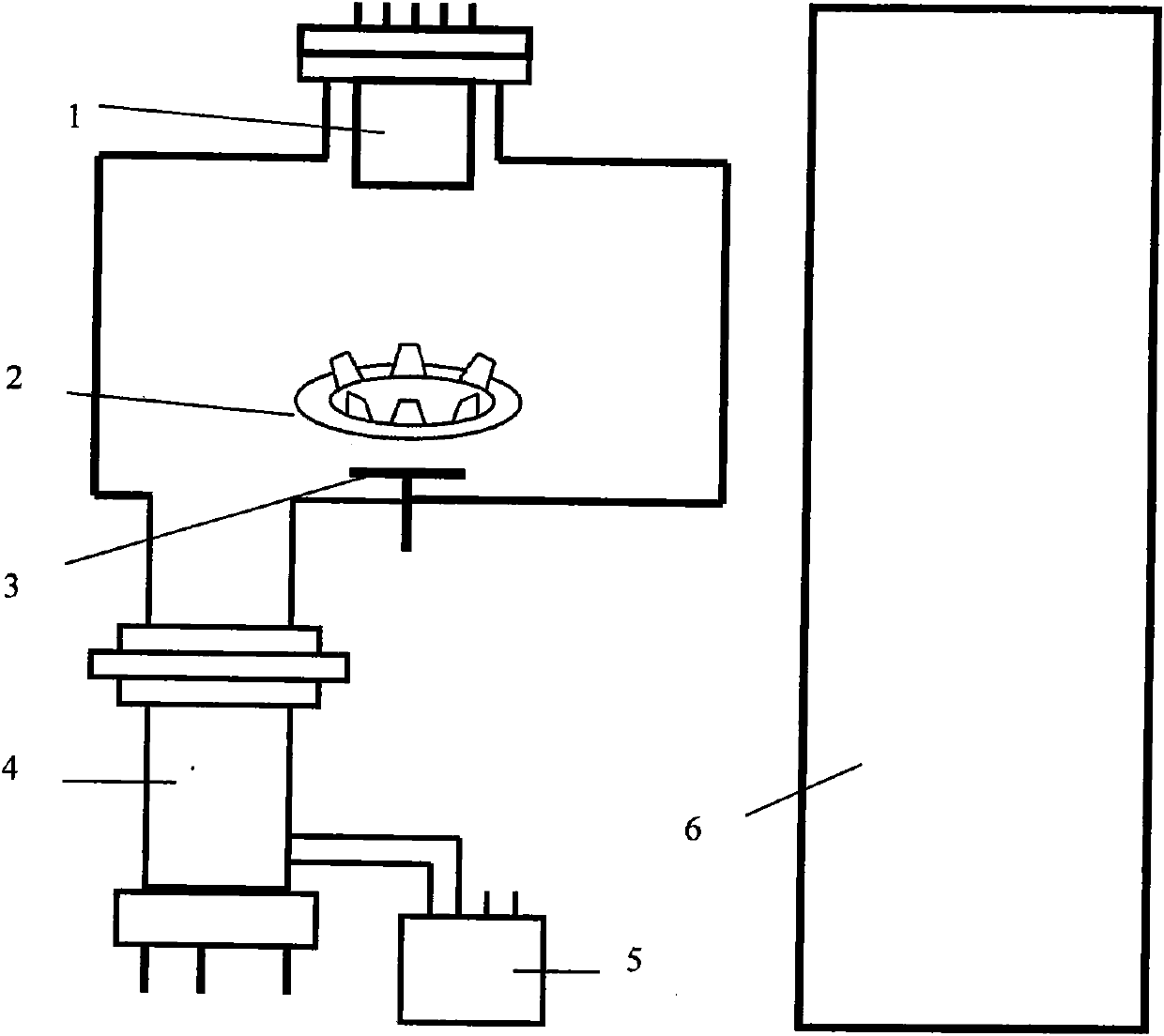

[0022] refer to figure 1 , showing a schematic diagram of ion beam surface treatment equipment that suppresses secondary electron emission. In the figure, the mechanical pump 5 in the pre-vacuum is connected to the secondary vacuum molecular pump 4 and the sample stage assembly 3, and a sputtering device is arranged above the sample stage assembly. The deposition assembly 2 is provided with a Kaufmann ion source 1 above the sputtering deposition assembly, and they form a sealed vacuum device, which is also connected to an electric control cabinet 6 .

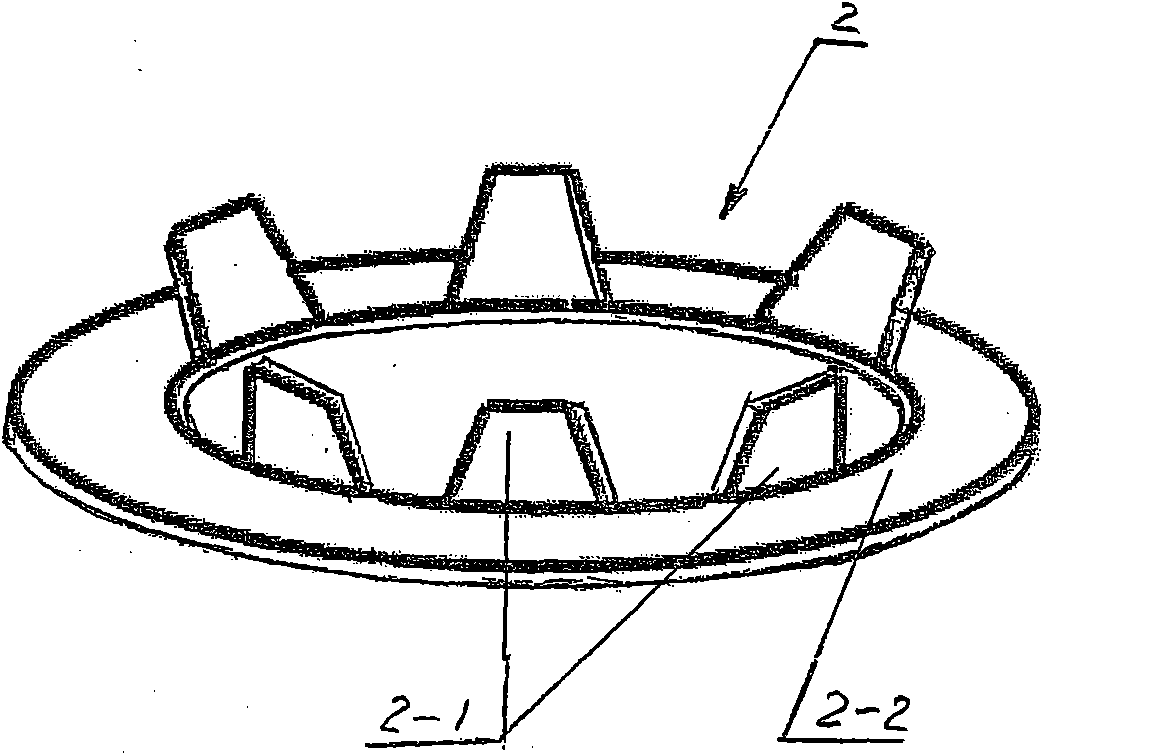

[0023] refer to figure 2 , represents a structural diagram of the sputtering deposition assembly, which is a ring-like structure with multiple fins on the edge, 2-1 in the figure is the fins, and there are gaps 2-2 between the fins.

[0024] refer to image 3 , represents the flow chart of the ion beam surface treatment method for suppressing secondary electron emission, in which the operation is performed according to the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com