A preparation method of a silver film trap structure for suppressing secondary electron emission on the surface of microwave components

A technology for secondary electron emission and microwave components, applied in the microwave field, can solve the problems of poor controllability and low yield, and achieve the effects of good repeatability, increased porosity, and increased surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a) Cleaning of microwave components: place the microwave components in acetone, absolute ethanol, and deionized water for ultrasonic cleaning for 15 minutes, dry and set aside;

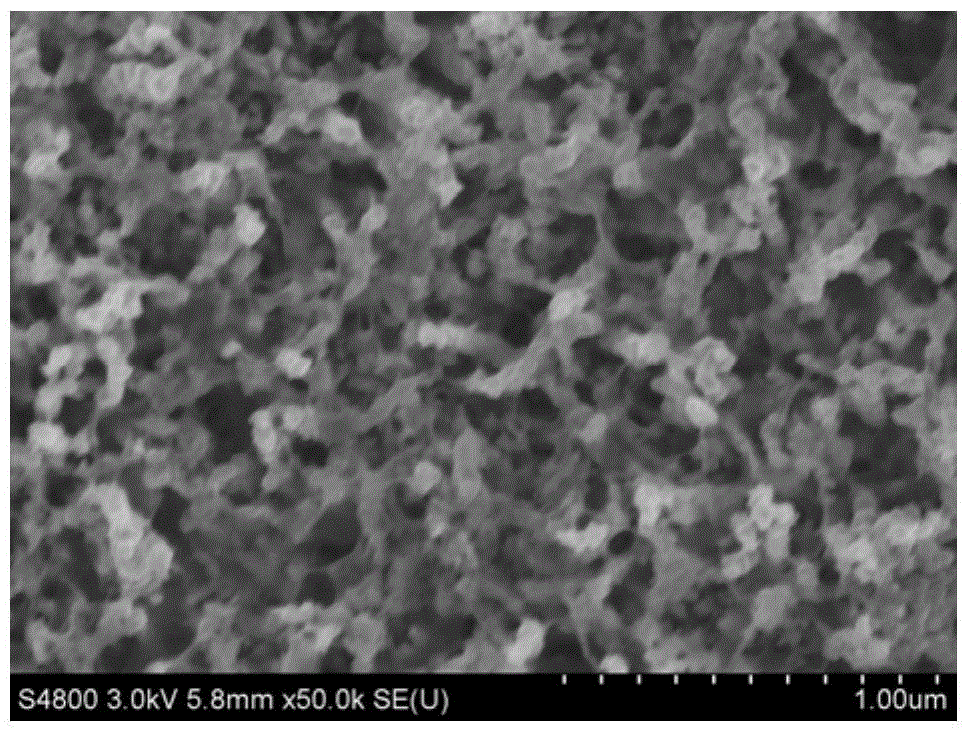

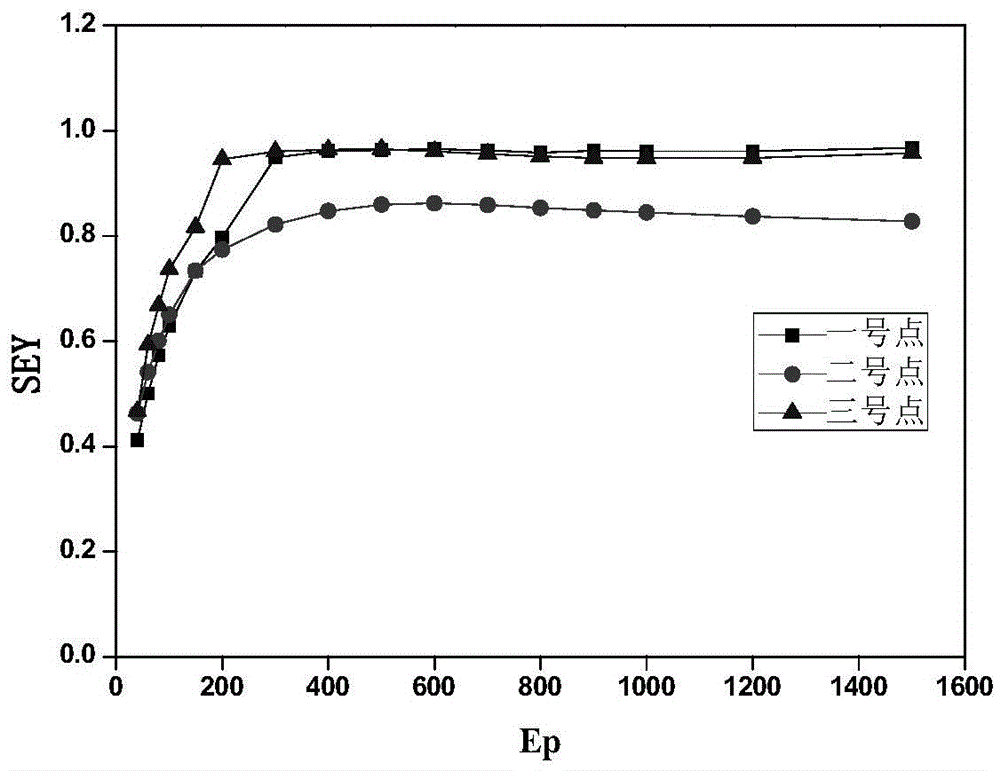

[0029] b) Preparation of ZnO nanoarrays: First, a layer of anhydrous ethanol solution of zinc acetate dihydrate with a concentration of 0.01mol / L was coated on the surface of microwave components by dip coating, then dried at 60°C, and successively Repeat the operation of coating and drying twice. Secondly, the microwave component was placed under a 300W ultraviolet lamp and irradiated for 30 minutes to prepare the seed crystal layer. Then, under the condition of room temperature and normal pressure, the above-mentioned microwave component containing the seed layer was placed face down (that is, the side on which the seed layer was grown was facing down), and placed obliquely in a zinc salt solution at 95° C. for 4 hours. After the growth is completed, the microwave component is taken out, cle...

Embodiment 2

[0032] a) Cleaning of microwave components: place the microwave components in acetone, absolute ethanol, and deionized water for ultrasonic cleaning for 15 minutes, dry and set aside;

[0033]b) Preparation of ZnO nanoarrays: First, a layer of anhydrous ethanol solution of zinc acetate dihydrate with a concentration of 0.04mol / L was coated on the surface of microwave components by dip coating, and then dried at 70°C, and repeated in sequence The operation of coating and drying was performed three times. Secondly, the microwave component was placed under a 300W ultraviolet lamp and irradiated for 40 minutes to prepare the seed crystal layer. Then, under the condition of room temperature and normal pressure, the above-mentioned microwave component containing the seed layer was placed face down (that is, the side on which the seed layer was grown was facing down), and placed obliquely in a zinc salt solution at 90° C. for 5 hours. After the growth is completed, the microwave com...

Embodiment 3

[0036] a) Cleaning of microwave components: place the microwave components in acetone, absolute ethanol, and deionized water for ultrasonic cleaning for 15 minutes, dry and set aside;

[0037] b) Preparation of ZnO nanoarrays: First, a layer of anhydrous ethanol solution of zinc acetate dihydrate with a concentration of 0.03mol / L was coated on the surface of microwave components by dip coating, then dried at 65°C, and sequentially The operation of coating and drying was repeated four times. Secondly, the microwave component was placed under a 300W ultraviolet lamp and irradiated for 50 minutes to prepare the seed crystal layer. Then, under the condition of normal temperature and normal pressure, the above-mentioned microwave component containing the seed layer was placed face down (that is, the side on which the seed layer was grown was facing down), and placed obliquely in a zinc salt solution at 92° C. for 4.5 hours. After the growth is completed, the microwave components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com