Method for preparing large-area polycrystalline film

A large-area, amorphous silicon thin-film technology, used in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. Improved photoelectric conversion efficiency, shortened process time, and high electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

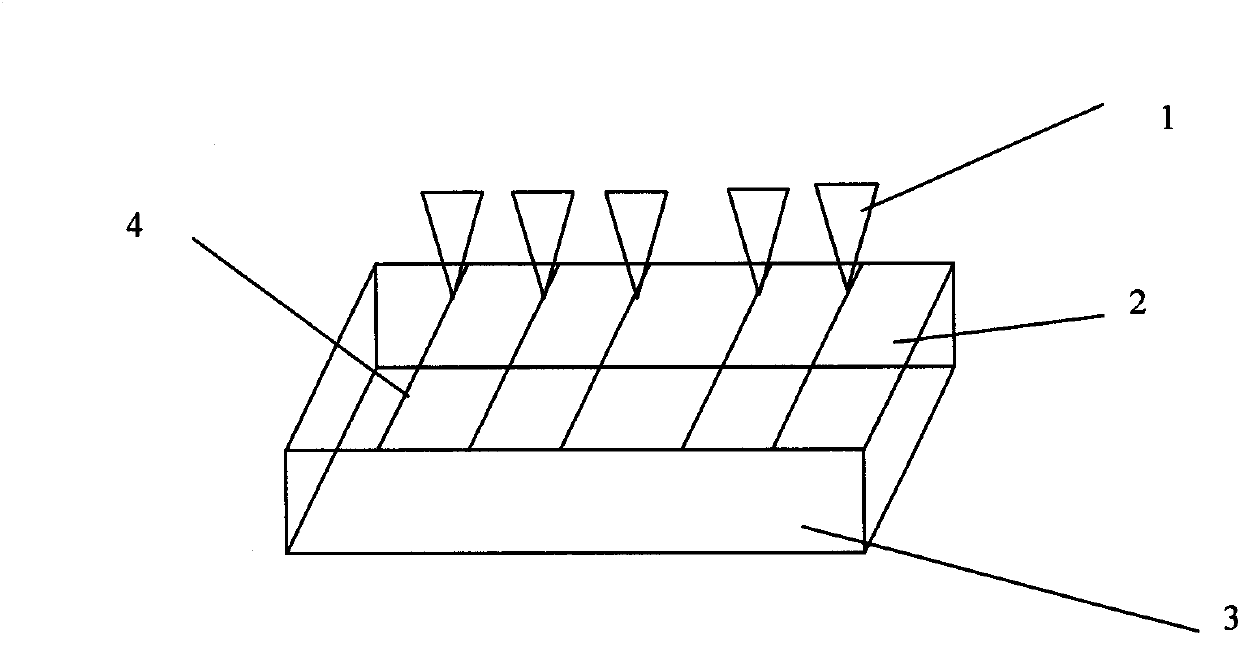

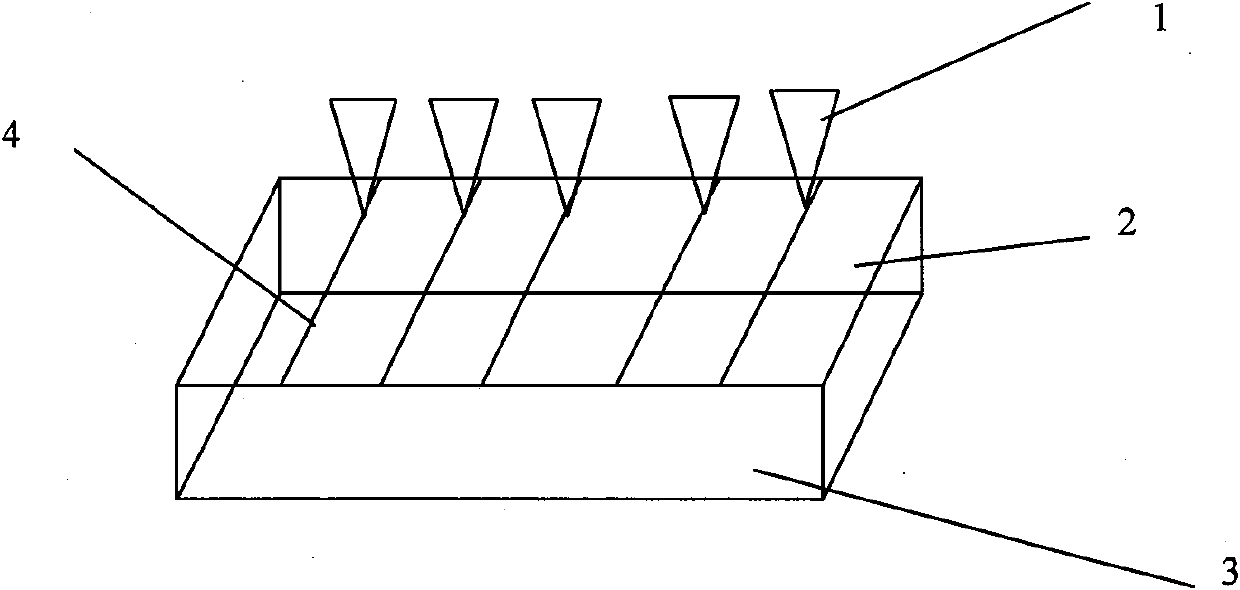

[0026] Combine below figure 1 The present invention is described further, and concrete process is as follows:

[0027] 1. Prepare a piece of ultra-clear glass 3. It is required to have better light transmittance. Deposit a-Si:H thin film 2 with PECVD method, thickness is for 150nm, with SiH 4 and H 2 As the reaction gas, the gas flow rate is 18mL / min, the substrate temperature is 220°C, and the reaction chamber pressure is 80Pa.

[0028] 2. On the basis of step 1, the strip window 4 is exposed by using a photolithography process, and the distance between the two strip windows is determined according to actual needs, and the distance is at the millimeter level.

[0029] 3. On the basis of step 2, use the magnetron sputtering method to sputter a layer of Ni metal layer on the amorphous silicon film, the position is on the amorphous silicon layer at the opened window, the thickness is 10nm, and the radio frequency sputtering power density 4W / cm 2 The substrate temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com