In-situ synthesizing and compounding method of desilting tip

A technology for in-situ synthesis and sedimentation, which is applied in the field of mining and selection equipment manufacturing, can solve the problems of inability to meet the wear resistance of sedimentation nozzles, affect the classification and separation effect of the cyclone, and tear into pieces, so as to avoid strengthening Phase interface weakening problem, good interface bonding effect, clean interface and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

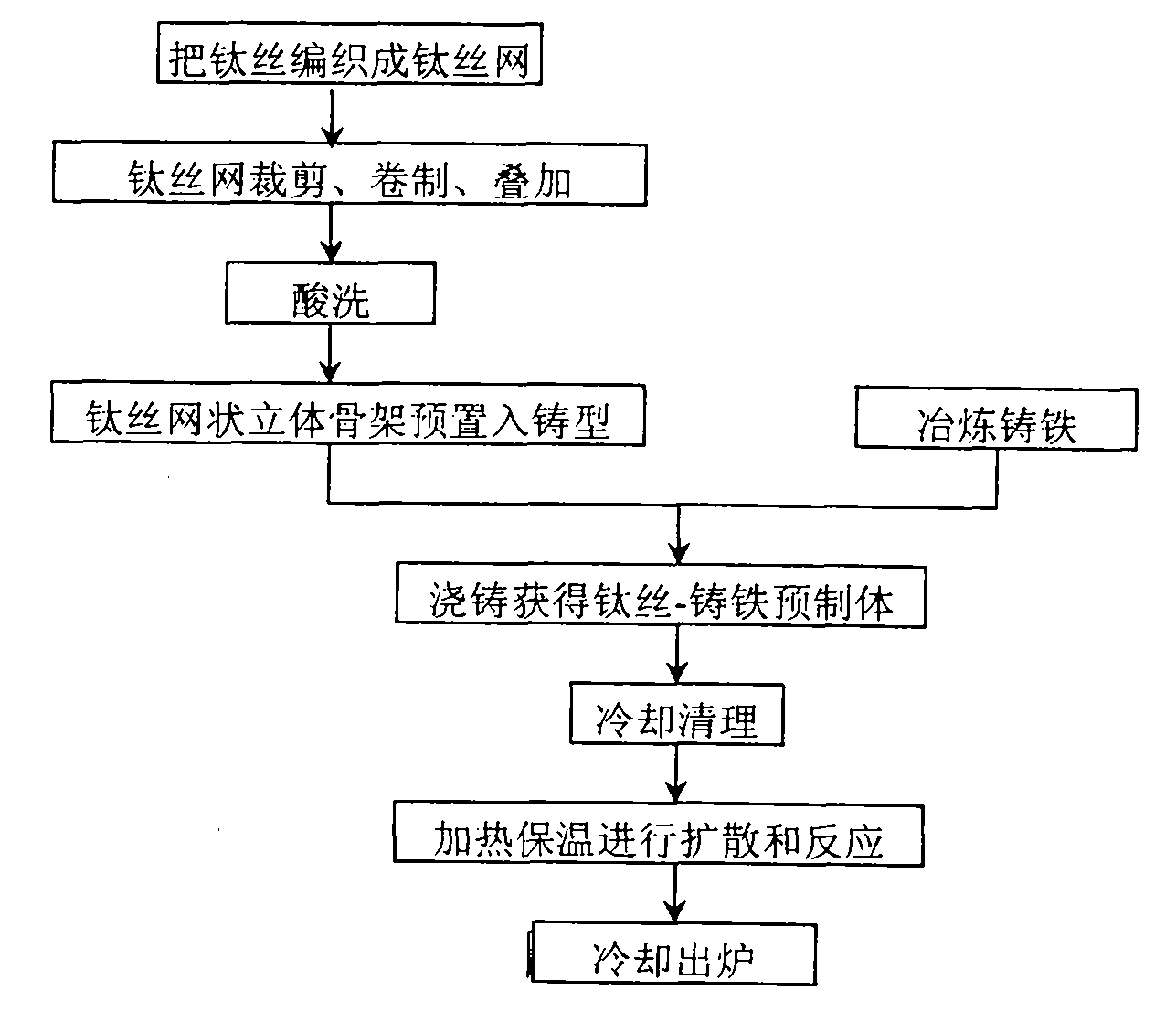

[0031] Example 1: Making partial composite sand sinking nozzles

[0032] (1) Weaving titanium wire mesh 1 with 2mm titanium wire, the spacing between titanium wires is 10mm;

[0033] (2) Titanium wire mesh 1 is cut, superimposed, and rolled into the shape of the sand sinking nozzle, and the superimposed thickness is 1 / 3 of the total thickness of the sand sinking nozzle;

[0034] (3) Pickling the titanium screen 1;

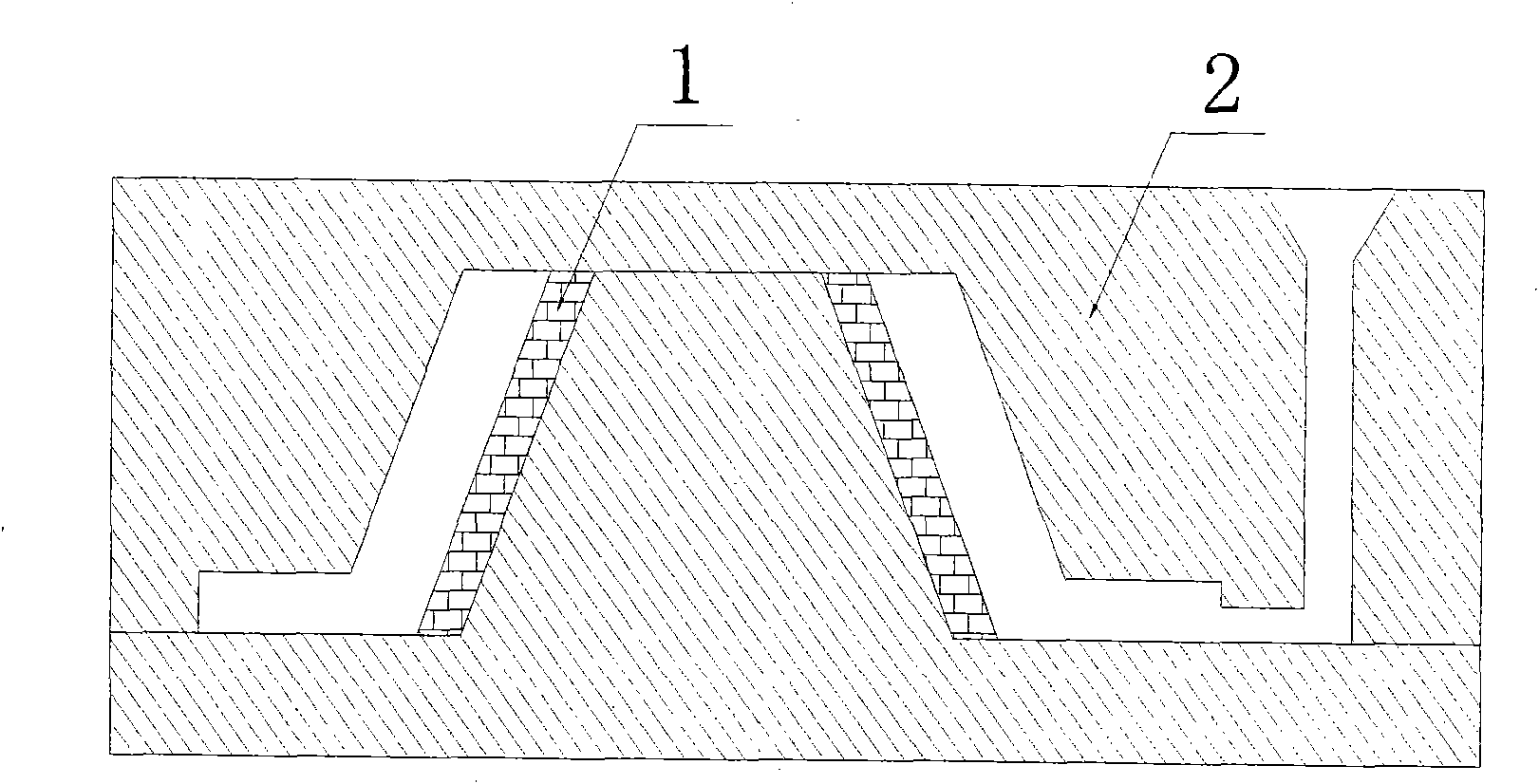

[0035] (4) Make mold 2 according to casting process requirements;

[0036] (5) Put the titanium mesh 1 into the cavity of the mold 2;

[0037] (6) smelting cast iron 3 to obtain liquid cast iron;

[0038] (7) Pour the liquid cast iron 3 into the mold to obtain a titanium wire-cast iron binary material preform;

[0039] (8) After cooling and stripping and cleaning, put the titanium wire-cast iron binary material prefabricated body into the heat treatment furnace;

[0040] (9) Insulate at a temperature of 1150°C for 90 minutes;

[0041] (10) After cooling with ...

Embodiment 2

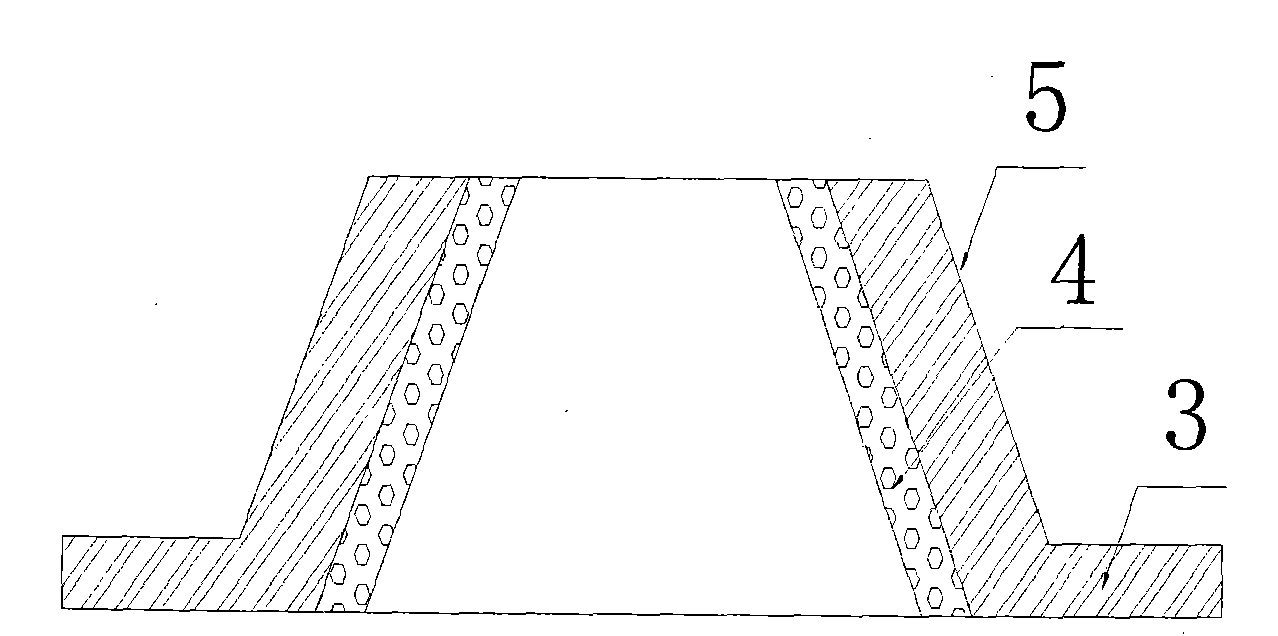

[0042] Embodiment 2: making integral composite material sand sinking nozzle

[0043] (1) Weave titanium wire mesh 1 with 0.5mm titanium wire, and the spacing between titanium wires is 2mm;

[0044] (2) Titanium wire mesh 1 is cut, superimposed, and rolled into the shape of a sand sink;

[0045] (3) Pickling the titanium screen 1;

[0046] (4) Make mold 2 according to casting process requirements;

[0047] (5) Put the titanium mesh 1 into the cavity of the mold 2;

[0048] (6) smelting cast iron 3 to obtain liquid cast iron;

[0049] (7) Pour the liquid cast iron 3 into the mold to obtain a titanium wire-cast iron binary material preform;

[0050] (8) After cooling and stripping and cleaning, put the titanium wire-cast iron binary material prefabricated body into the heat treatment furnace;

[0051] (9) Insulate at a temperature of 1300°C for 60 minutes;

[0052] (10) After cooling with the furnace, it is released from the furnace, and the sand sinking nozzle 5 of the cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com