Modified polyurethane resin emulsion dye ink and application thereof

A technology of polyurethane resin and dye ink, applied in polyurea/polyurethane coatings, applications, inks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

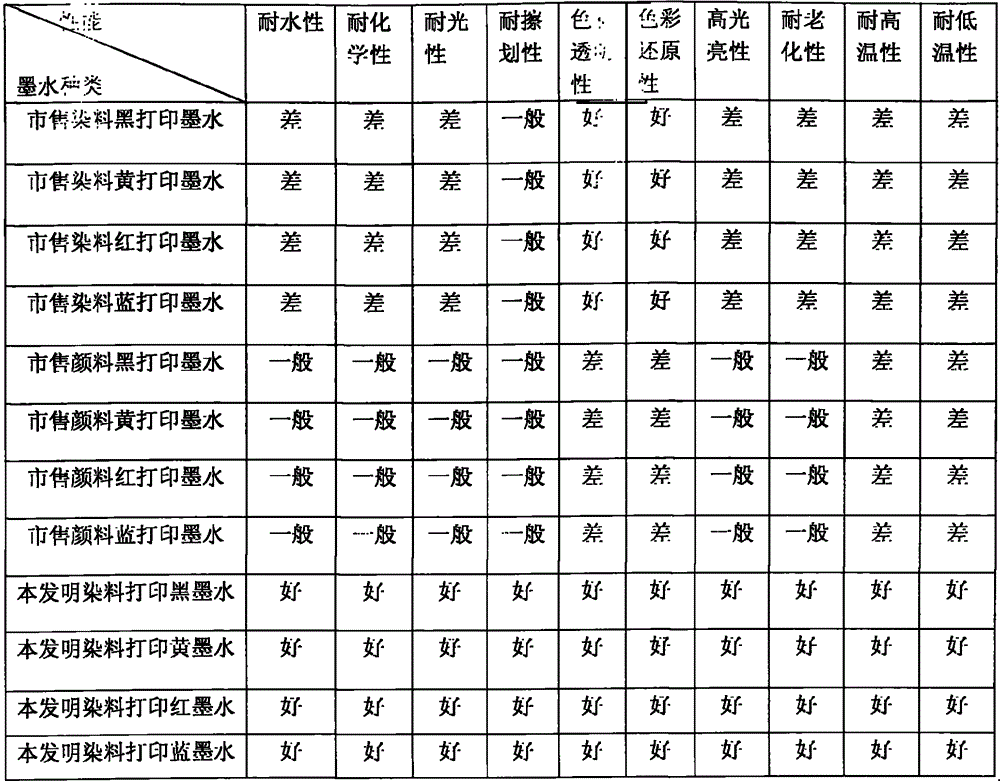

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: Preparation of modified polyurethane resin color emulsion

[0075] 1: Weigh 5g of Acid Scarlet GR, dissolve in water, wait until completely dissolved, and filter. When filtering, filter the dye with chronic qualitative filter paper, called dye solution.

[0076] 2: Mix 90mL of solvent with 0.1mol of toluene diisocyanate (TDI) and add it to a three-necked flask protected by nitrogen, and add 3 drops of catalyst dibutyltin dilaurate (DBT), and heat up to 60°C (use acetone as When the solvent is used, the reaction temperature is slightly lower), slowly drop a certain amount of organosilicon (hydroxyl-terminated silicone oil), drop it in about 1.5 hours, and continue the reaction for 1.5 hours after the dropwise addition. Then a certain amount of polyisopropylene glycol (PPG, Mn=1000) was added dropwise for about 1.5 hours, and the reaction was continued for 1.5 hours after the dropwise addition was completed. Let cool to room temperature.

[0077] 3: quickly...

Embodiment 2

[0079] Embodiment 2: Addition amount of dyestuff, modified polyurethane resin emulsion and water resistance and chemical resistance experiment:

[0080] According to the national QB / T 2063-2007, GB / T 18724-2008 / ISO 2836:2004 standard testing.

[0081] Get dyestuff acid bright red GR and solvent dyestuff golden light bright red respectively to make ink, dye amount is 0.1,0.5,1,2,3,4,5,6,7,8,9,10,11,12 (weight %), set into a beaker, add an appropriate amount of solvent and / or wetting agent, stir evenly, filter with chronic qualitative filter paper, then take modified polyurethane resin emulsion (solid content in modified polyurethane resin emulsion is 30 ± 2%), with 10, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 80, 90 (weight %), add water and other additives (total amount 100%), form several formulas respectively (orthogonal experiment), stirred evenly, and filtered again through a microporous membrane to prepare water-based dye and solvent dye ballpoint pen ink. Wash the c...

Embodiment 3

[0098] Embodiment 3: can be used as inkjet ink, inkjet ink, textile printing ink, water-based ballpoint pen ink

[0099] Component Weight

[0100] Acid Scarlet GR 0.1%

[0101] Diethylene glycol 10%

[0102] Silicone-polyurethane resin emulsion (resin solid content is 30%) 55%

[0103] Benzophenone 0.3%

[0104] Benzotriazole 0.2%

[0105] Diethylene glycol butyl ether 10%

[0106] Isobutanol 12.4%

[0107] Methyl isobutyl ketone 10%

[0108] Titanate coupling agent 2%

[0109] Preparation method: prepare according to preparation method three. Quantitatively weigh 0.1g of Acid Scarlet GR, dissolve in 10g of diethylene glycol, then add 10g of diethylene glycol butyl ether, 10.4g of isobutanol, 10g of methyl isobutyl ketone, stir well, filter with chronic qualitative filter paper, add organic 55 g of silicone-polyurethane resin emulsion, 0.3 g of diphenmethanone, and 0.2 g of benzotriazole. Dissolve 2g of titanate coupling agent with 2g of isobutanol, add it into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com