Synthetic methane catalyst and preparation method and application thereof

A technology for synthesizing methane and catalysts, which is applied in the field of catalysts for synthesizing methane and its preparation, and can solve problems such as resistance to high temperature and resistance to hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

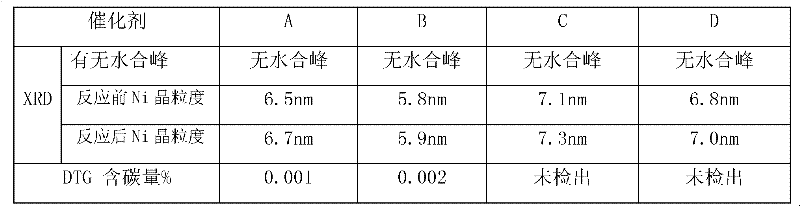

Embodiment 1

[0031] Weigh 23.5g of boehmite (aluminum hydroxide), add 500ml of 3% nitric acid solution, stir for 1 hour, add 59g of nickel nitrate hexahydrate and 131g of zirconium oxychloride octahydrate. Lanthanum nitrate 22g, cerium nitrate 5g, dissolved in 100ml deionized water, and mixed with the previous solution, heated to 40°C, neutralized with 5% sodium carbonate to pH 9, precipitated, filtered, washed, at 120°C Dry for 12 hours, press into tablets, then dry at 120°C for 12 hours, put it into a muffle furnace for calcination, the heating rate is 4°C / min, the temperature is 900°C, and the calcination time is 6 hours to obtain catalyst A. The specific surface is 102m 2 / g, the pore volume is 0.44ml / g.

[0032] The application of the catalyst is carried out in a fixed bed, the catalyst is placed in the middle of the constant temperature zone of the reactor, and the upper and lower sides are supported by stainless steel mesh and quartz sand. The reaction temperature is 600°C, the re...

Embodiment 2

[0034]Weigh 59g of nickel nitrate hexahydrate, 131g of zirconium oxychloride octahydrate, 22g of lanthanum nitrate, and 5g of cerium nitrate, dissolve them in 500ml of ion-free water, heat the solution to 50°C, and neutralize with 5% sodium carbonate to a pH of 9. Precipitate, filtered, washed, dried at 120°C for 14 hours, pressed into tablets, then dried at 120°C for 12 hours, put into a muffle furnace for calcination, heating rate 4°C / min, temperature 1000°C, calcination constant temperature time For 8 hours, Catalyst B was obtained. The measured surface area is 76m 2 / g, pore volume 0.33ml / g.

[0035] The application of the catalyst is carried out in a fixed bed, the catalyst is placed in the middle of the constant temperature zone of the reactor, and the upper and lower sides are supported by stainless steel mesh and quartz sand. The reaction temperature is 650°C, the reaction pressure is 5MPa, and the space velocity is 3000h -1 , the volume percentage of raw gas is com...

Embodiment 3

[0037] Weigh 23.5g of boehmite (aluminum hydroxide), add 500ml of 3% nitric acid solution, stir for 1 hour, add 59g of nickel nitrate hexahydrate and 131g of zirconium oxychloride octahydrate. Calcium nitrate 6g, lanthanum nitrate 22g, cerium nitrate 5g, dissolved in 100ml deionized water, mixed with the previous solution, heated to 60°C, neutralized with 5% sodium carbonate to pH 9.5, precipitated, filtered and washed , dried at 110°C for 16 hours, pressed into tablets, then dried at 110°C for 16 hours, put into a muffle furnace for calcination, the heating rate was 4°C / min, the temperature was 900°C, and the calcination constant temperature time was 8 hours to obtain the catalyst c. The specific surface area of the catalyst is 96m 2 / g, pore volume 0.42ml / g.

[0038] The application of the catalyst is carried out in a fixed bed, the catalyst is placed in the middle of the constant temperature zone of the reactor, and the upper and lower sides are supported by stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com