Method for continuously producing 1, 1, 2-trichloroethane

A technology of trichloroethane and dichloroethane, which is applied in the field of production 1, can solve the problems of being unsuitable for large-scale industrial production, maintaining a low processing capacity, and difficult separation, and achieves enhanced stability and ease of operation , reduced energy consumption and unit consumption, simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

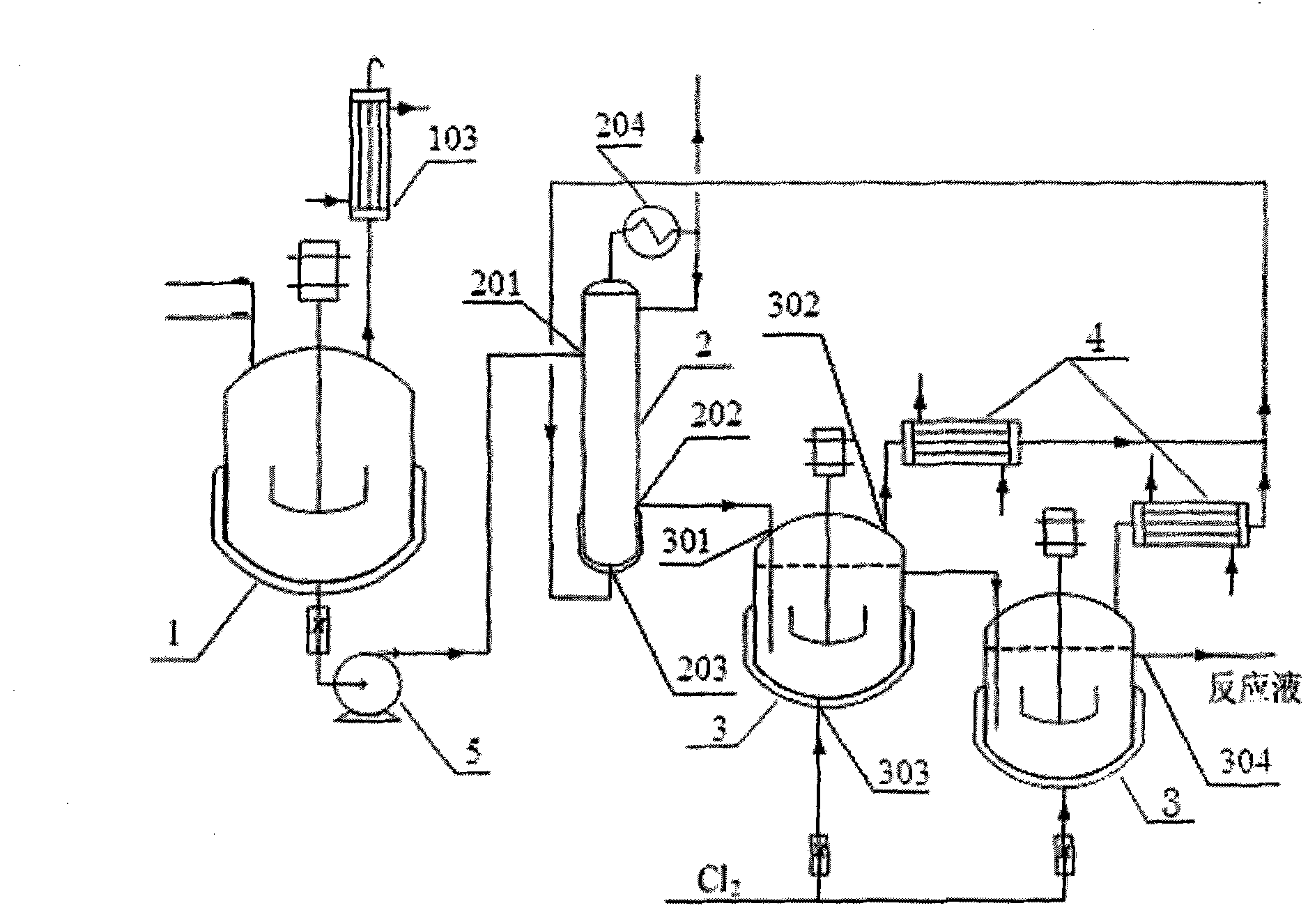

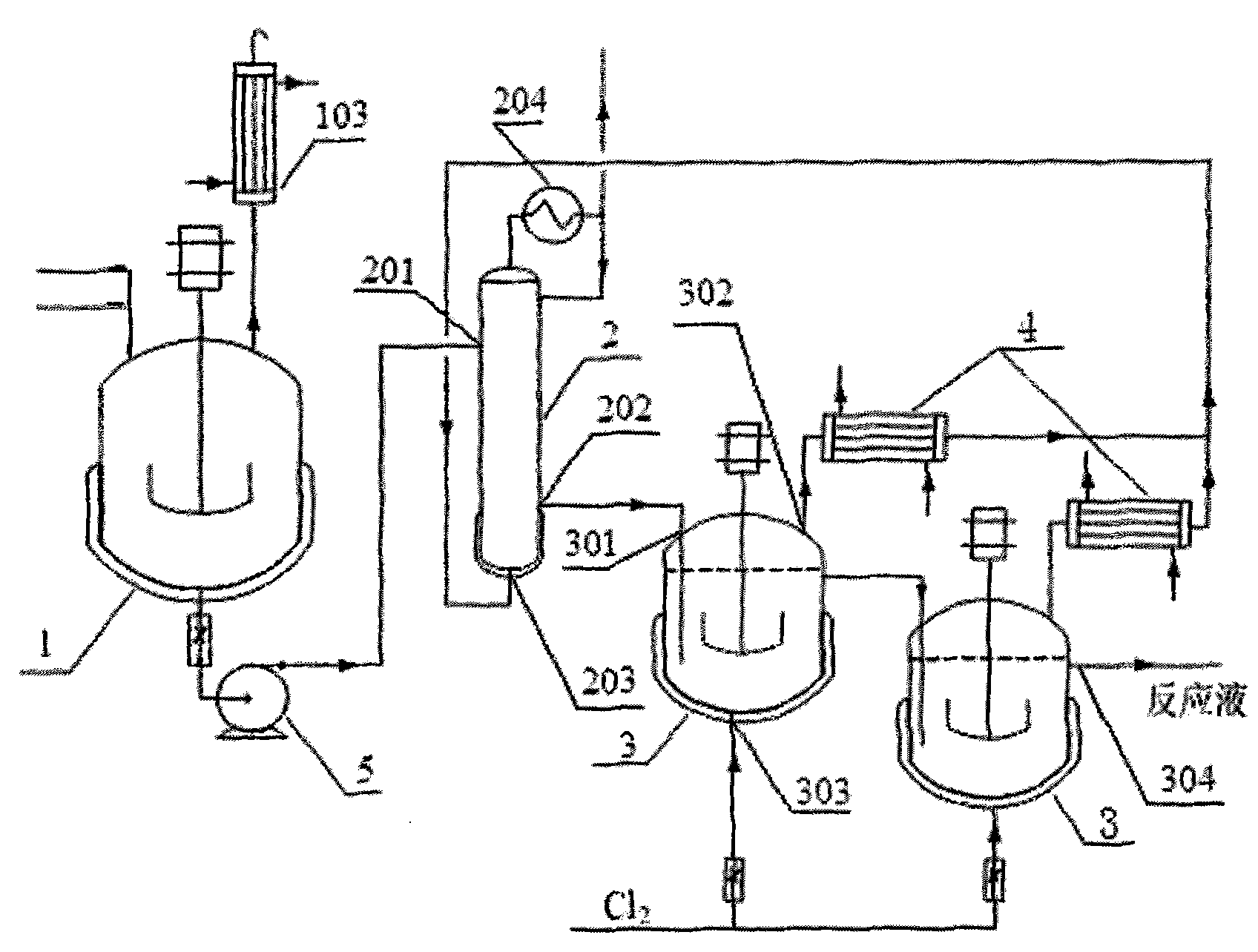

[0037] use figure 1 The flow process shown produces 1,1,2-trichloroethane, and is provided with two stirring absorption tanks 3;

[0038] Structural parameters of each device:

[0039] Stirring preheating kettle 1 is a 100L stainless steel kettle, pre-reaction packing tower 2 is made of stainless steel lining enamel, the inner diameter of the tower is 40cm, the height of the tower is 2.5 meters, and the height of the packing layer is 1.5 meters. The kettle 3 is a 50L enamel kettle, the stirring preheating kettle 1 and the stirring absorption kettle 3 both use anchor-type stirring paddles, and the condensers are all enamel tubular condensers with a heat exchange area of 1m 2 .

[0040] Process parameters are as follows: the feed rate of 1,2-dichloroethane is 60kg / h, using azobisisobutyronitrile as initiator, the addition is 1.5‰ (with 1,2-dichloroethane weight ratio), The mol ratio of 1,2-dichloroethane and chlorine is: 1: 0.75, and the chlorine feed weight ratio of the fi...

Embodiment 2

[0043] The same apparatus as in Example 1 was used.

[0044] 1, the feed rate of 2-dichloroethane is 80kg / h, uses dibenzoyl peroxide as initiator, and add-on is 2‰ (with 1,2-dichloroethane mass ratio), 1,2- The molar ratio of dichloroethane and chlorine is: 1:0.8, the chlorine feed weight ratio of the first stirred absorption tank 3 and the second stirred absorption tank 3 is 1.75:1, the system is heated by steam, and the reaction is continued for 48 hours After the system stabilizes, the temperature in the stirring preheating tank 1 is kept at 54.5°C, the temperature in the reaction section of the pre-reaction packed tower 2 is kept at 59.6°C, the temperature in the first stirring absorption tank 3 is kept at 66.8°C, and the temperature in the second stirring absorption tank 3. The internal temperature is maintained at 85.4°C. Under these operating conditions, the reaction selectivity is 91.6%, the conversion rate is 78.2%, and the mass concentration of 1,1,2-trichloroethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com