Method for preparing a waterborne poly(urethane acrylate)/nano-titanium dioxide hybrid material

A nano-titanium dioxide and water-based polyurethane technology is applied in the field of preparation of polyurethane emulsion modification. The effect of sufficient raw material source and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

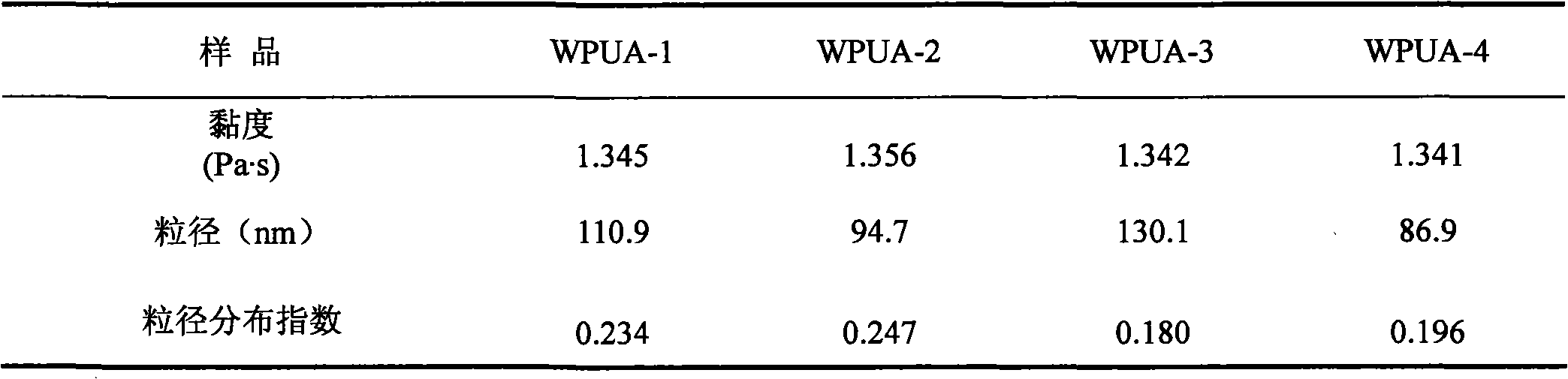

Examples

Embodiment 1

[0014] (1) In a container equipped with a stirring device, add dehydrated ethanol, whose consumption accounts for 56% of the total substance by volume, and a certain amount of n-butyl titanate (TBT), hydrochloric acid, distilled water and dehydrated alcohol ( The volume ratio is 10:2:1:10) the mixed solution was added into the container, and stirred at room temperature for 1 hour to obtain a homogeneous clear solution, that is, TBT sol.

[0015] Add a certain amount of 20g of N-220 and 5g of DMPA into a 500ML four-necked bottle equipped with a stirrer, reflux condenser, thermometer and feeding device, use NMP as a solvent, raise the temperature of the system to 70°C, add 15g of IPDI, drop Add 0.5g of T-12 as a catalyst, raise the temperature of the system to 90°C, react for 6 hours (if the viscosity of the system is too high, add a certain amount of acetone), cool down to 50°C, add 8g of HEMA, keep warm for 5 hours, then lower the temperature To 40°C, add triethylamine, react ...

Embodiment 2

[0017] (1) In a container equipped with a stirring device, add dehydrated ethanol, whose consumption accounts for 56% of the total substance by volume, and a certain amount of n-butyl titanate (TBT), hydrochloric acid, distilled water and dehydrated alcohol ( The volume ratio is 10:2:1:10) the mixed solution was added into the container, and stirred at room temperature for 1 hour to obtain a homogeneous clear solution, that is, TBT sol.

[0018] Add 10g of N-220 and 5g of DMPA into a 500ML four-necked bottle equipped with a stirrer, reflux condenser, thermometer and feeding device, use NMP as a solvent, raise the temperature of the system to 50°C, add 15g of MDI, and dropwise add 0.3g of T -12 is the catalyst, raise the temperature of the system to 80-85°C, react for 3 hours (if the system viscosity is too high, add a certain amount of acetone), cool down to 60°C, add 6g of HEMA, keep warm for 6 hours, then cool down to 50°C, add triethylamine, react for 30min, add 5g of ethyl m...

Embodiment 3

[0020] (1) In a container equipped with a stirring device, add dehydrated ethanol, whose consumption accounts for 56% of the total substance by volume, and a certain amount of n-butyl titanate (TBT), hydrochloric acid, distilled water and dehydrated alcohol ( The volume ratio is 10:2:1:10) the mixed solution was added into the container, and stirred at room temperature for 1 hour to obtain a homogeneous clear solution, that is, TBT sol.

[0021] Add a certain amount of 10g of GE-210 and 1.7g of DMPA into a 500ML four-necked bottle equipped with a stirrer, reflux condenser, thermometer and feeding device, use NMP as a solvent, raise the temperature of the system to 60°C, add 10g of IPDI, Add 0.1g T-12 as a catalyst dropwise, raise the temperature of the system to 80-85°C, react for 4 hours (if the system viscosity is too high, add a certain amount of acetone), cool down to 60°C, add 5.75g of HEMA, keep warm and continue the reaction After 5 hours, cool down to 40°C, add triethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com