Preparation method of rare earth-doped calcium tungstate phosphor

A technology of rare earth doping and calcium tungstate, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of phosphor luminous intensity or luminous wavelength influence, and achieve low production cost, cheap price and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take the commercially available cuttlefish bone, peel off the skin, and take its spongy inner layer for later use. Weigh 0.30g of peeled spongy cuttlebone in the reaction kettle, then weigh 0.75g of ammonium tungstate so that the mass ratio of peeled spongy cuttlebone to ammonium tungstate is 2:5, and place in the reaction In the kettle, weigh 0.043g (0.1mmol) of La(NO 3 ) 3 ·6H 2 O is placed in a reaction kettle, 10ml of distilled water is added, sealed, and reacted in an oven at a temperature of 120° C. for one day. Cool to room temperature, rinse with distilled water, and then dry at 100°C for 2h, take a small piece of sample and calcinate at 200°C, 600°C and 900°C for 2h respectively to obtain calcium tungstate phosphor doped with rare earth lanthanum .

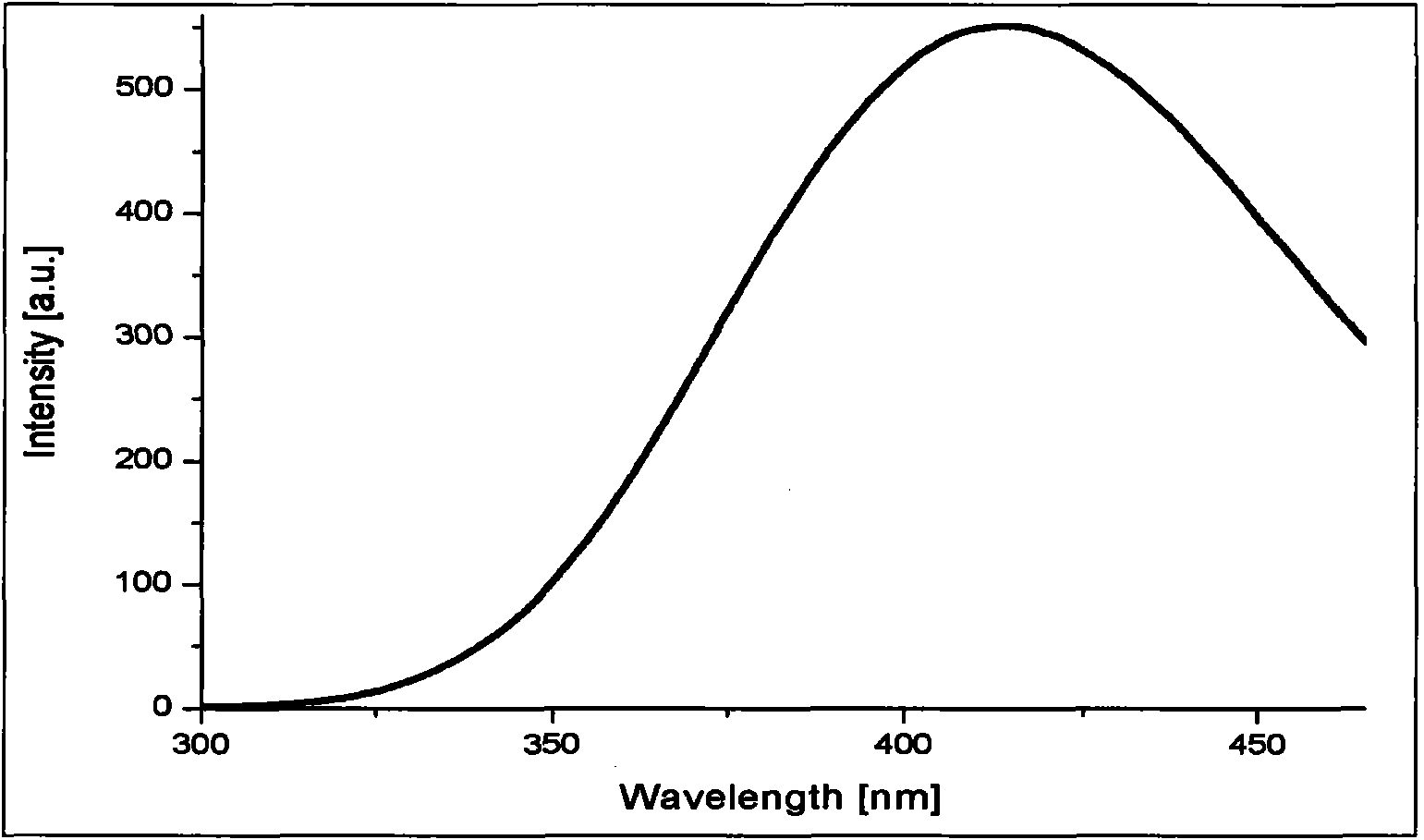

[0024] Fluorescence tests were carried out on the calcined samples respectively. Fluorescence analysis showed ( figure 1 ), when calcined to above 700°C, the product has a higher luminous intensity at 414nm u...

Embodiment 2

[0026] Take cuttlefish bones available in the market, peel off the skin, take the spongy inner layer, cut into blocks, and set aside. Weigh 0.30g of peeled spongy cuttlebone in the reaction kettle, then weigh 0.50g of ammonium tungstate, make the mass ratio of peeled spongy cuttlebone to ammonium tungstate be 3:5, place in In the reactor, weigh 0.044g (0.1mmol) of Nd(NO 3 ) 3 ·6H 2 O was placed in a reaction kettle, 10ml of distilled water was added, sealed, and reacted at a temperature of 160°C for one day. Cool to room temperature, rinse with distilled water, and then dry at 120°C for 3 hours, take a small piece of sample and calcinate at 200°C, 600°C and 900°C for 2 hours respectively to obtain calcium tungstate phosphor doped with rare earth neodymium .

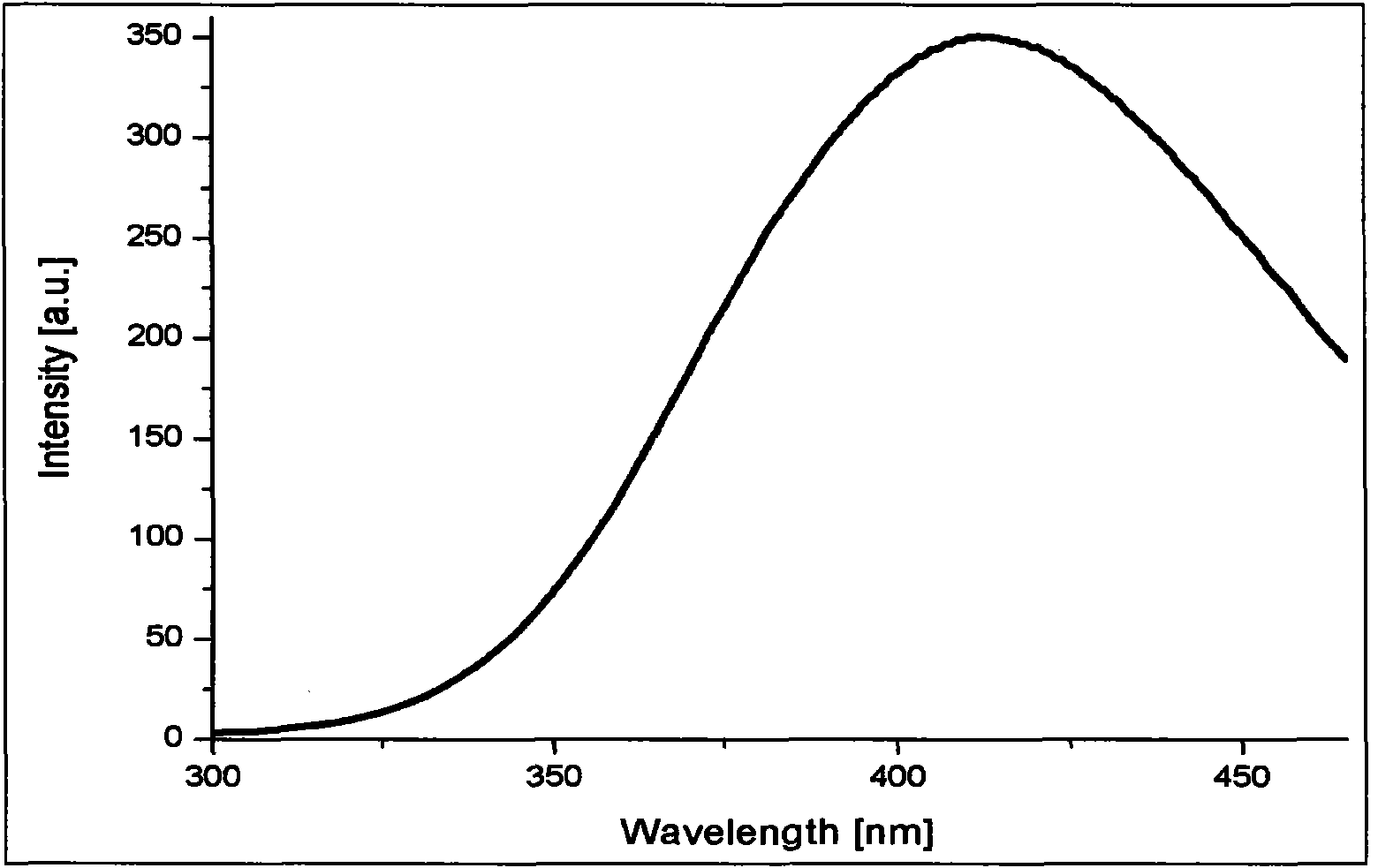

[0027]Fluorescence tests were carried out on the calcined samples respectively. Fluorescence analysis showed ( figure 2 ), when calcined to above 600°C, the product has a higher luminous intensity at 413nm under th...

Embodiment 3

[0029] Take the commercially available cuttlefish bone, peel off the skin, take its spongy inner layer, cut it into blocks, and set aside. Weigh 0.40g of peeled sponge cuttlebone in the reactor, then weigh 0.50g of ammonium tungstate so that the mass ratio of peeled sponge cuttlebone to ammonium tungstate is 4:5, and place it in the reactor Inside, weigh 0.034g (0.1mmol) of Tb(NO 3 ) 3 ·6H 2 O was placed in a reaction kettle, 10ml of distilled water was added, sealed, and reacted at a temperature of 180°C for one day. Cool to room temperature, rinse with distilled water, and dry at 150°C for 5 hours. Take a small piece of sample and calcinate at 200°C, 600°C and 900°C for 2 hours to obtain rare earth terbium-doped calcium tungstate phosphor .

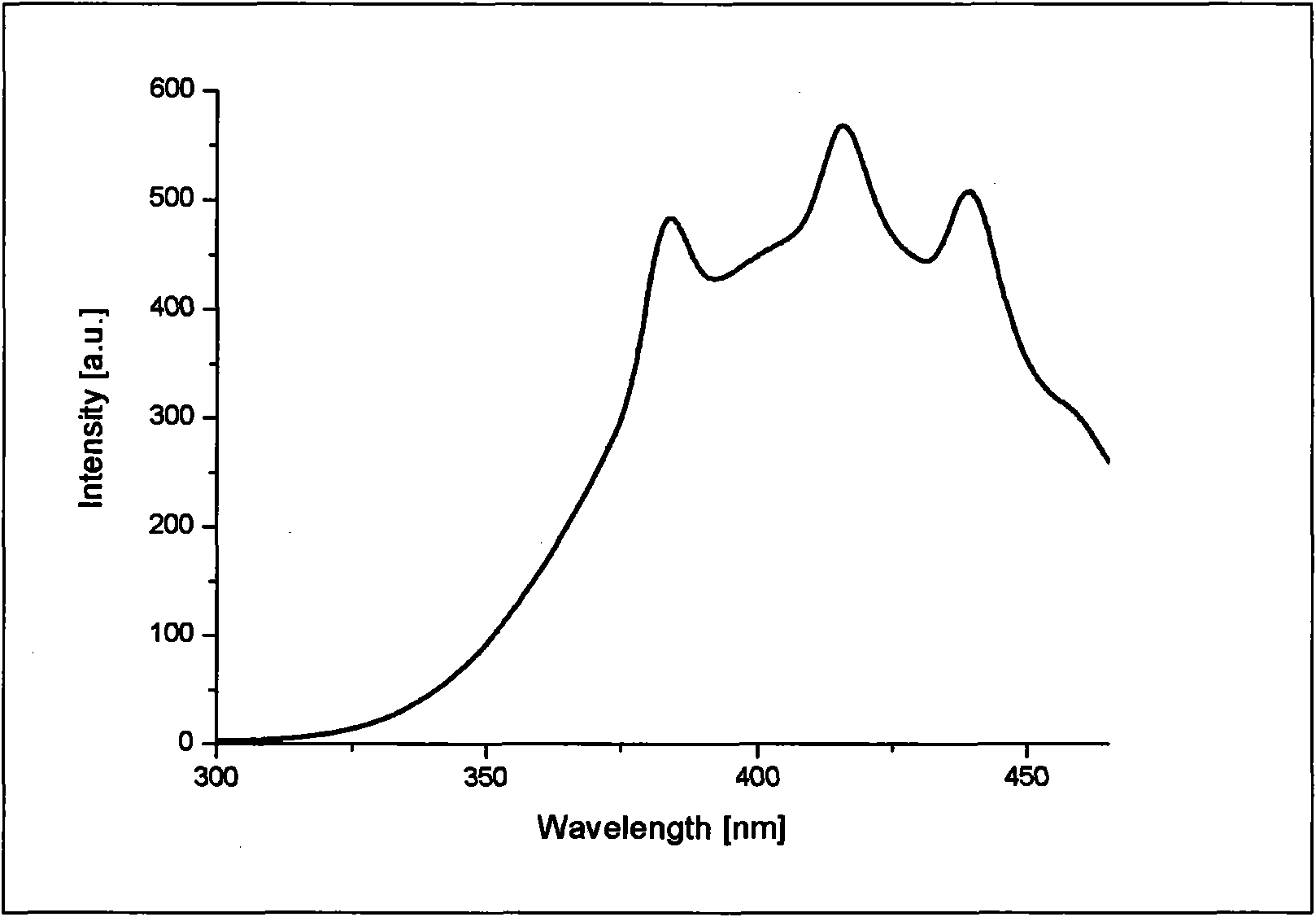

[0030] Fluorescence tests were carried out on the calcined samples respectively. Fluorescence analysis showed ( image 3 ), when calcined to above 900°C, the product has higher luminous intensity at 383nm, 417nm and 438nm under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com