Static aerobic fermentation drying tower and application

An aerobic fermentation, fermentation and drying technology, applied in the application, climate change adaptation, organic fertilizer and other directions, can solve the problems of easy corrosion of equipment, high processing cost, high product moisture, and achieves a small footprint, small investment, and fermentation heat. The effect of penetrating thin layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

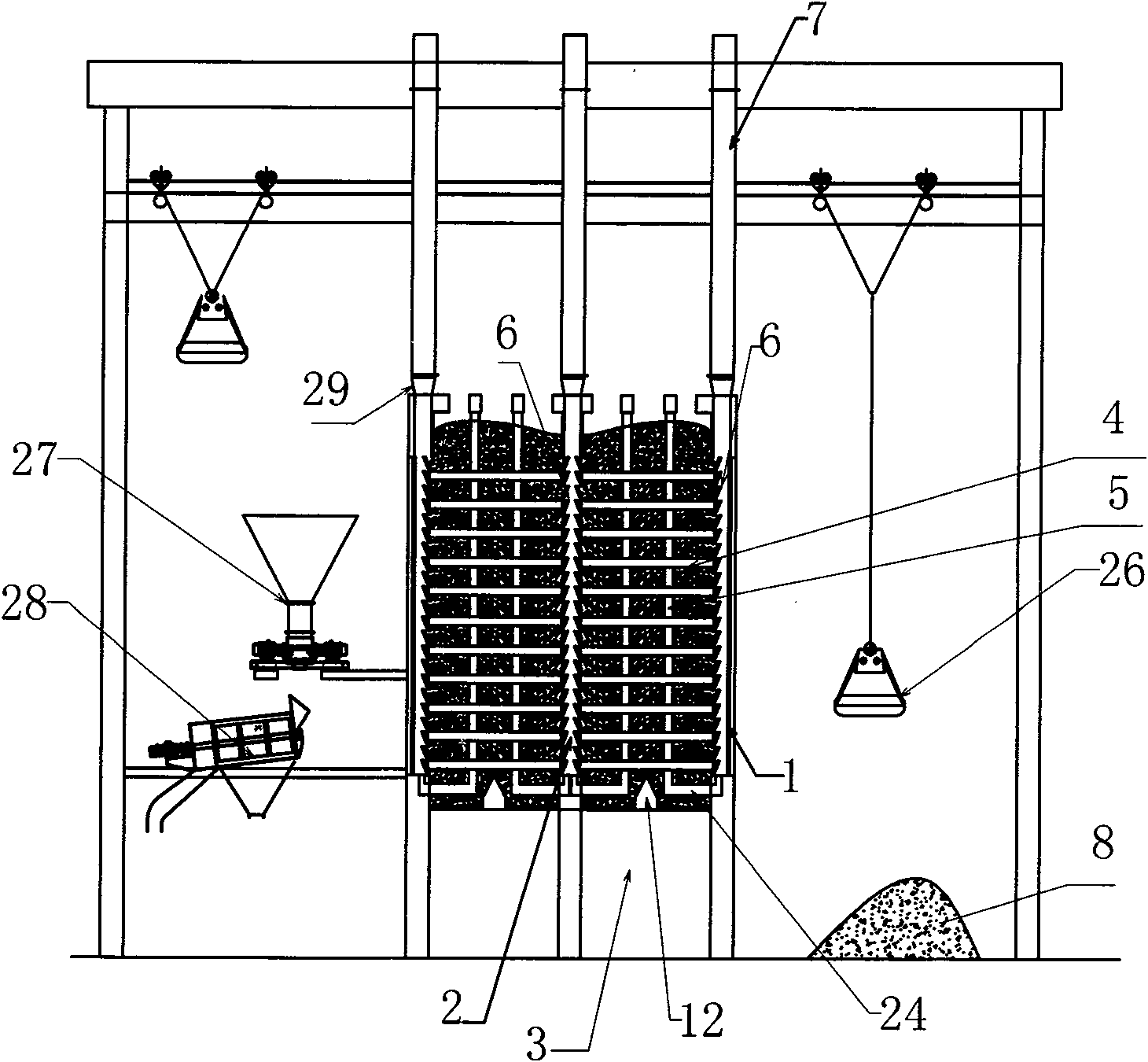

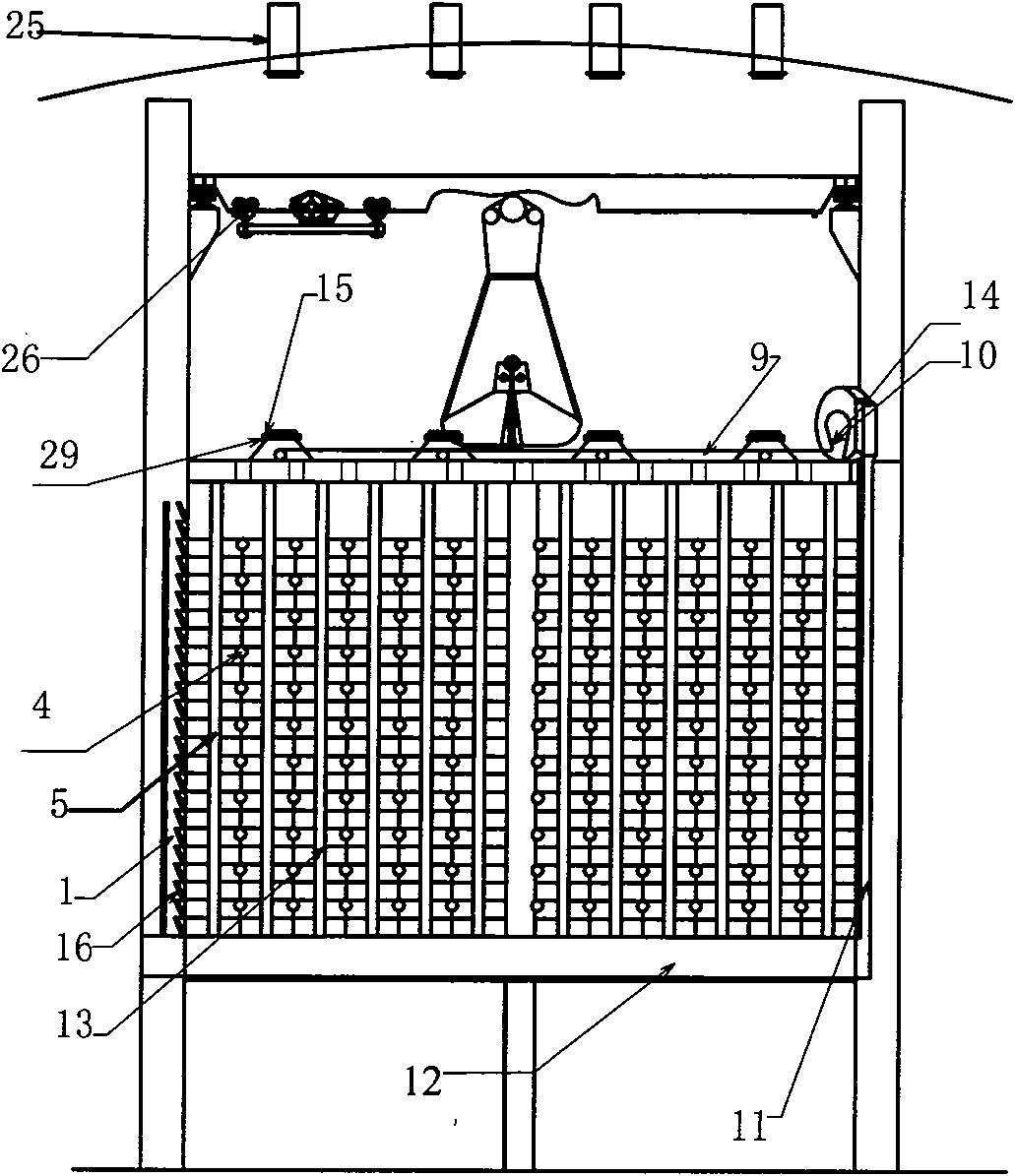

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

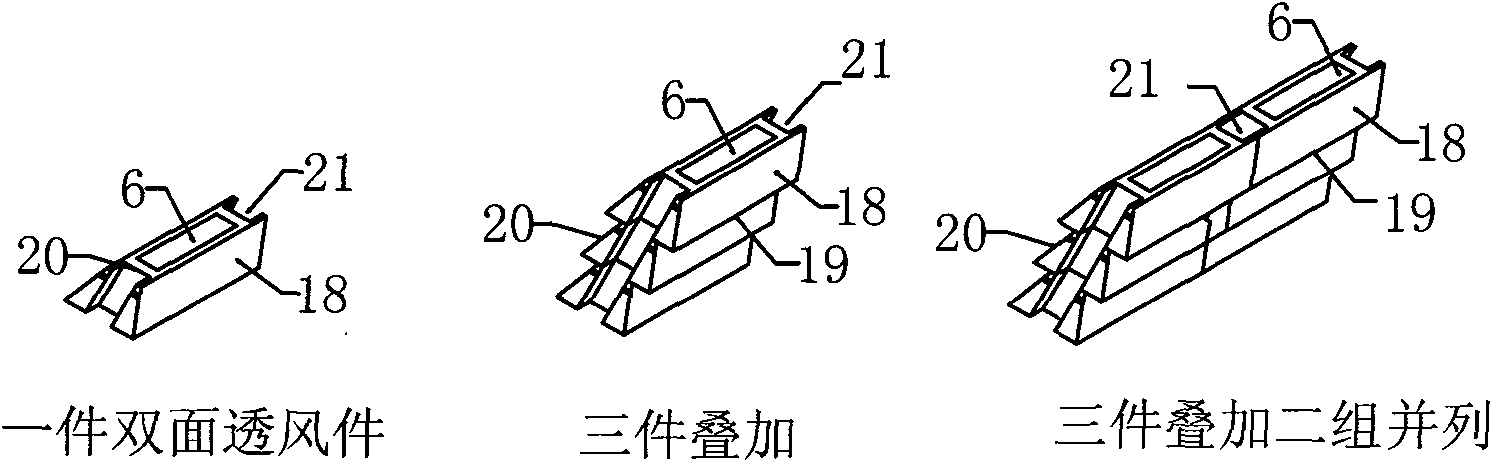

[0029]Ten fermentation and drying rooms (3) are designed in the present embodiment, each room has a capacity of 100 to 180 cubic meters and a heap height of 5 to 8 meters. Since most of the fermentation materials are corrosive to a certain extent and a large amount of hot and humid gas and corrosive substances are produced during the fermentation process, the fermentation drying tower of this embodiment uses reinforced concrete materials to make the tower body and ventilation parts, and the ventilation pipes are combined with engineering plastics (such as PVC or ABS materials). pieces. In the fermentation and drying room (3), several ventilation horizontal pipes (4) are distributed horizontally in the material, and the ventilation vertical pipes (5) are distributed at intervals. The pipe (5) is evenly spaced from the ventilating walls on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com