Vanillin-tolerant saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and vanillin, which is applied in microorganism-based methods, fungi, microorganisms, etc., can solve the problems of incomplete elucidation of the inhibition mechanism of phenolic compounds, lack of quantitative and qualitative analysis methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 Saccharomyces cerevisiae directed domestication

[0018] The starting strain used for directional domestication is Saccharomyces cerevisiae EM-13, and the domestication steps are as follows:

[0019] (1) After activation, Saccharomyces cerevisiae strain EM-13 was first cultured in YEPD liquid medium (20%-SECE-YEPD) prepared with a concentration of 20% corn stalk steam explosion material extract (hereinafter referred to as SECE), and inoculated Amount is OD 初始 =0.1, when the bacteria grow to the logarithmic phase, the same inoculum size (OD 初始 =0.1) were transferred to the same medium (20%-SECE-YEPD), and the transfer was repeated in this way, and each transfer was called an acclimatization batch.

[0020] (2) During the acclimatization process, monitor the OD value and glucose consumption of each batch at 11 hours. When the glucose consumption at 11 hours no longer increases and is basically stable, increase the SECE concentration of the next batch of acc...

Embodiment 2

[0025] Embodiment 2 domesticated culture screening

[0026] The domesticated culture obtained in Example 1 was pre-screened, pre-screened and re-screened to finally obtain vanillin-tolerant Saccharomyces cerevisiae, and the strain was named EMV-8 (preserved in "China Microorganisms" on July 16, 2010 Species Preservation Management Committee General Microbiology Center", the preservation number is CGMCC No.4012), and the screening steps are as follows:

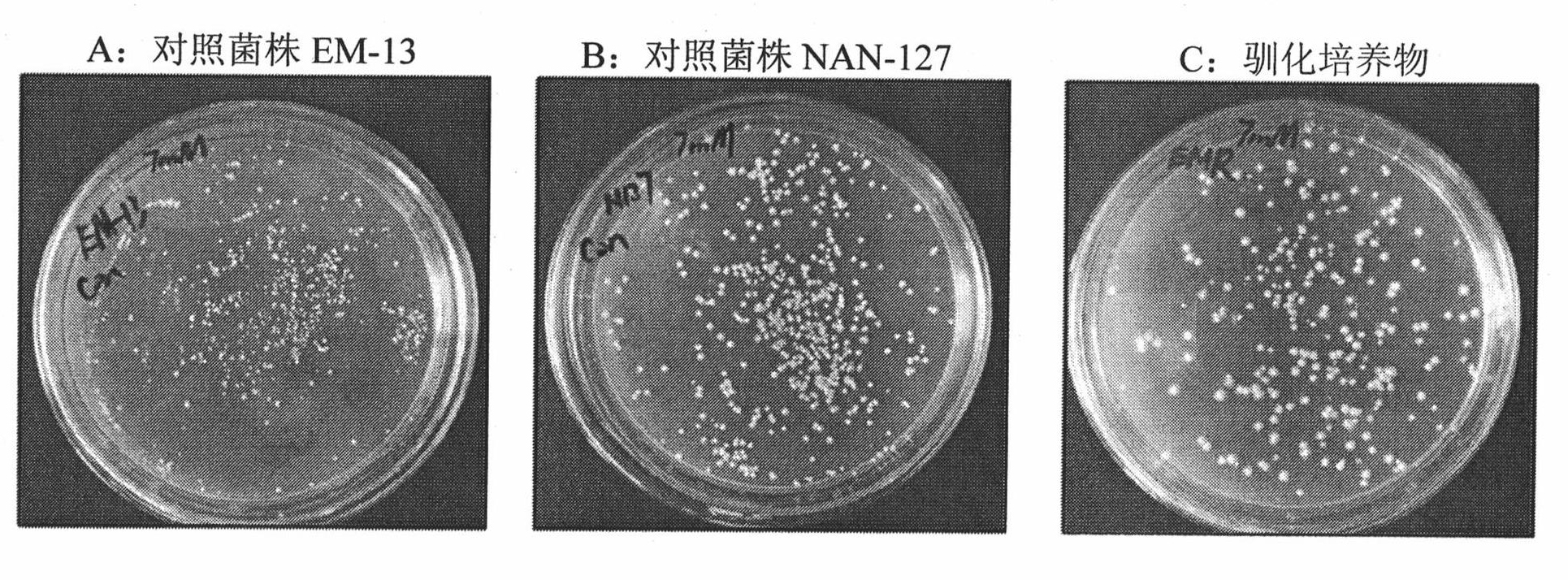

[0027] (1) Pre-screening on the dilution plate: Dilute the acclimatization culture solution to a suitable concentration and spread it on the pre-screening solid medium plate, and also dilute the culture solution of strains NAN-127 and EM-13 to a suitable concentration and spread it on the pre-screening As a control, culture on a solid medium plate in an incubator at 30°C. During the culture, observe the colony growth time, colony size and color, and select the colony with a shorter growth time, large colony and normal color (se...

Embodiment 3

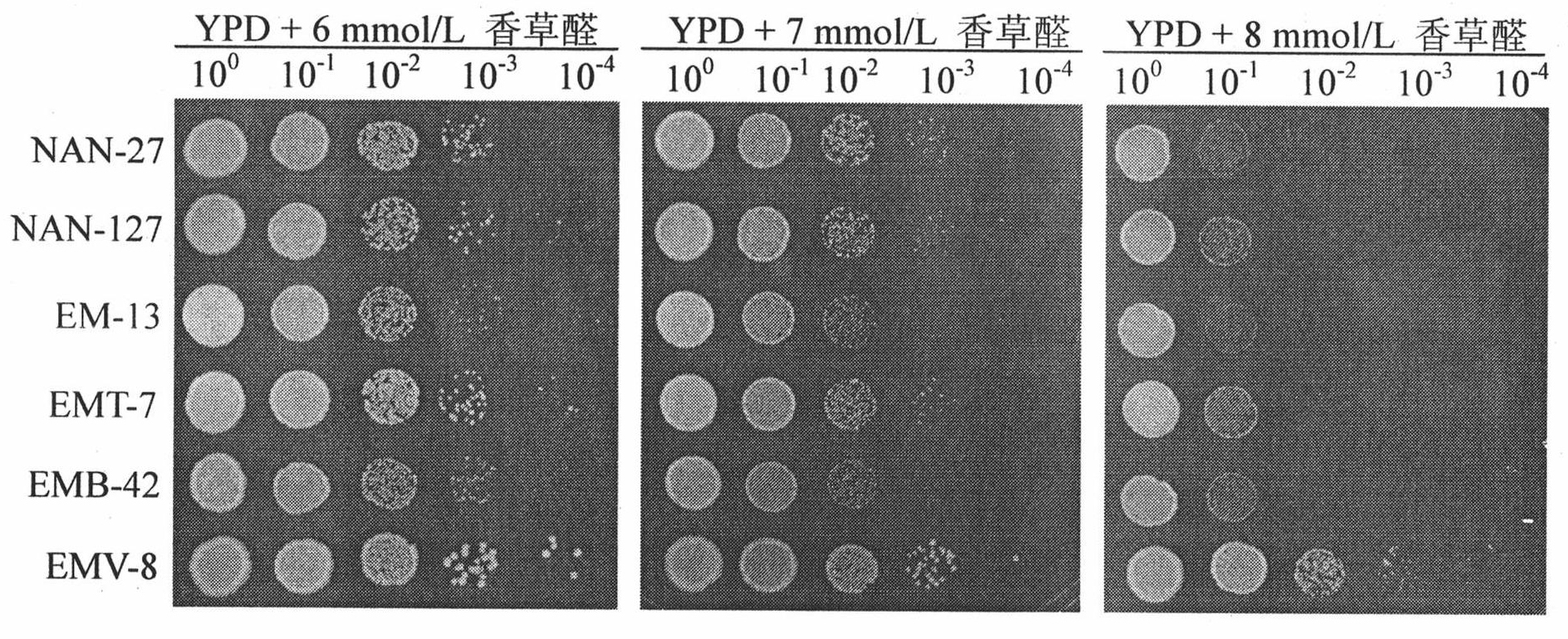

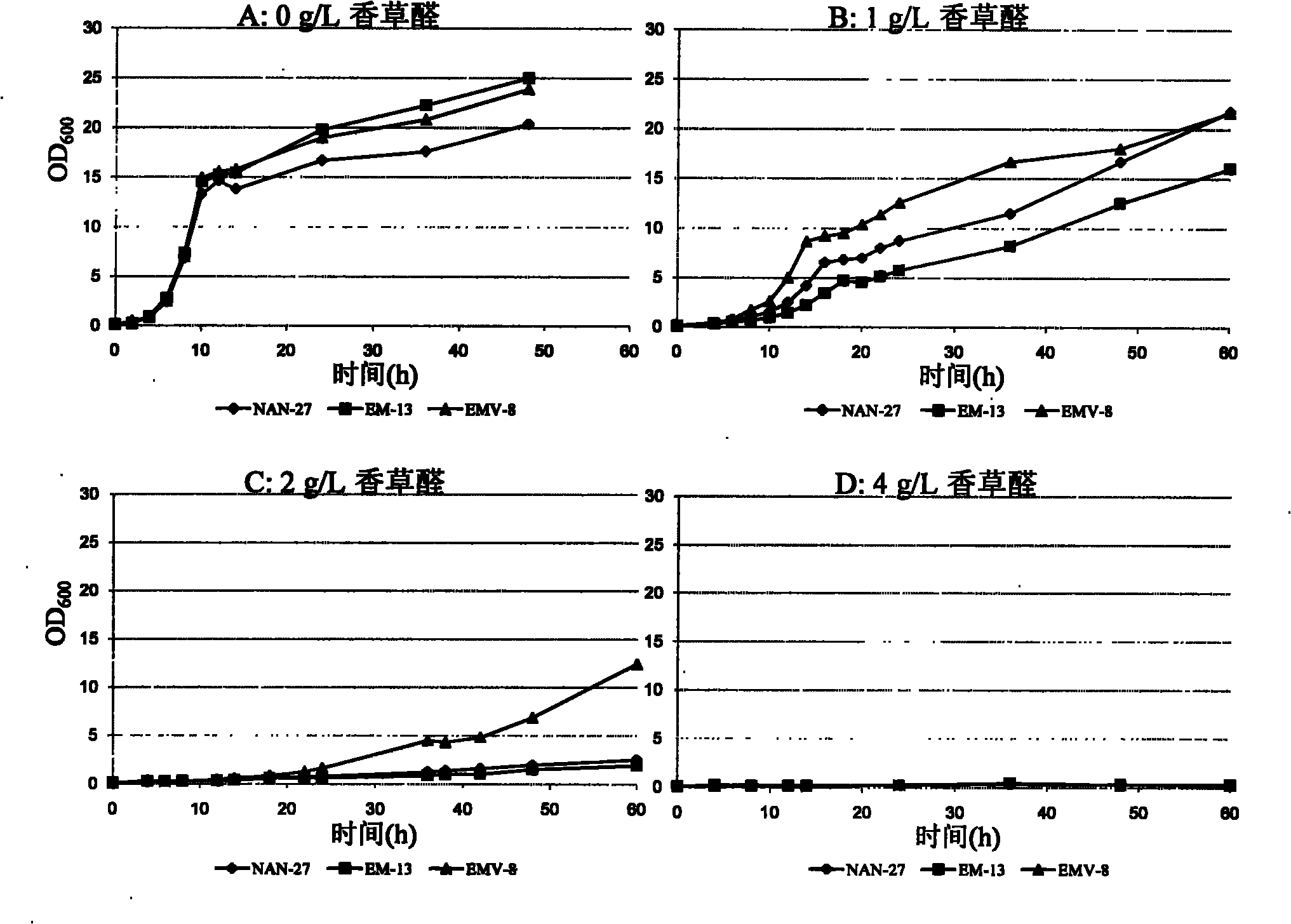

[0035] Example 3 Detection of vanillin tolerance of bacterial strain EMV-8

[0036] The bacterial strain EMV-8 obtained by screening in Example 2 is tested for vanillin tolerance, and the steps are as follows:

[0037] (1) Activation of slant strains: respectively pick 1 ring of the slant-preserved strain EMV-8 and control strains EM-13 and NAN-27 and culture them in 20mL YEPD liquid medium. The shaker speed is 200r / min, preferably at 30°C Oxygen culture for 24 hours.

[0038] (2) Seed preparation: OD according to inoculum size 初始 =0.2 The cultures in step (1) were respectively transferred to 20 mL YEPD liquid medium for culture, the speed of the shaker was 200 r / min, and aerobic culture was carried out at 30° C. for 12 hours.

[0039] (3) Shake flask culture: OD according to the inoculum size 初始 =0.1 The cultures in step (2) were respectively transferred to the vanillin tolerance detection medium for culture, the shaker speed was 200r / min, and the oxygen-limited culture wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com