Premix forfermented total mixed rations (TMR) for dairy cows and preparation process thereof

A preparation process and premix technology, applied in the application, animal feed, animal feed, etc., to achieve the effect of improving utilization, increasing milk production, and improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

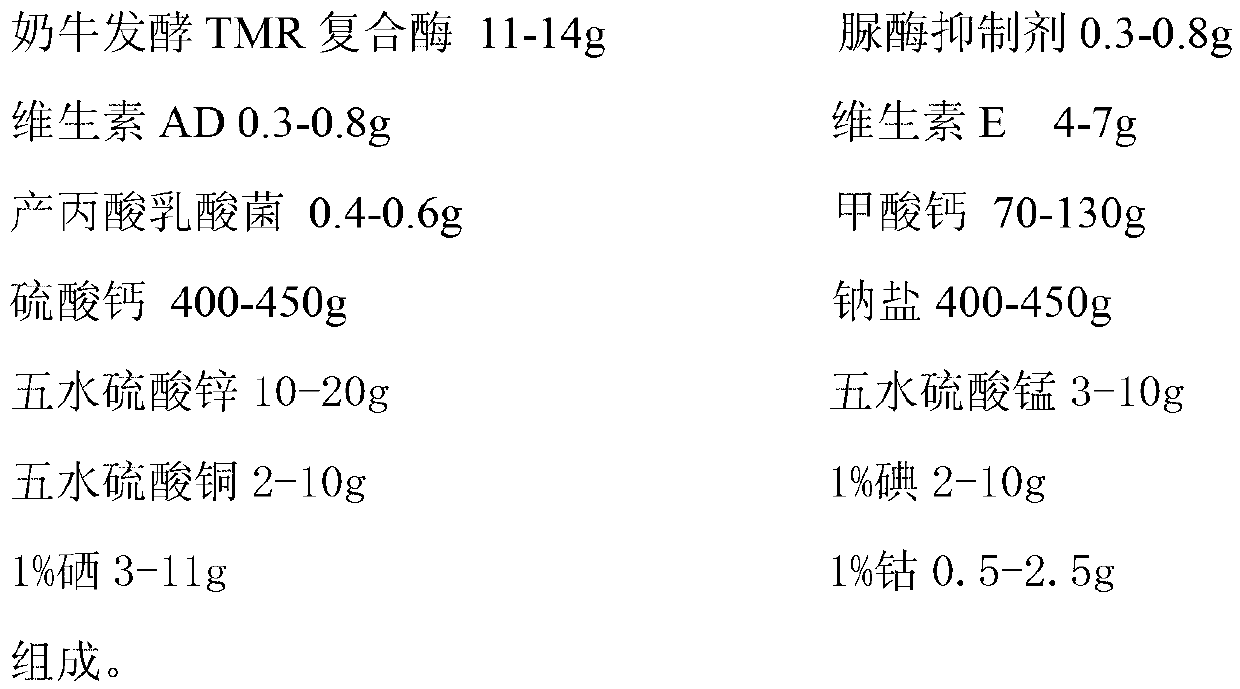

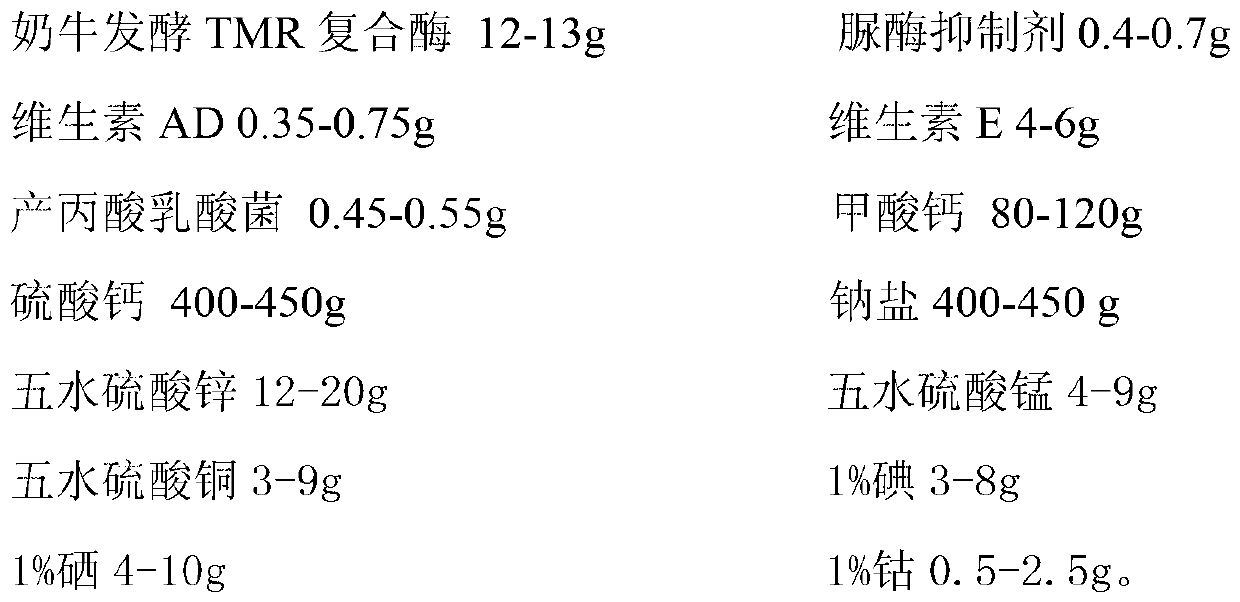

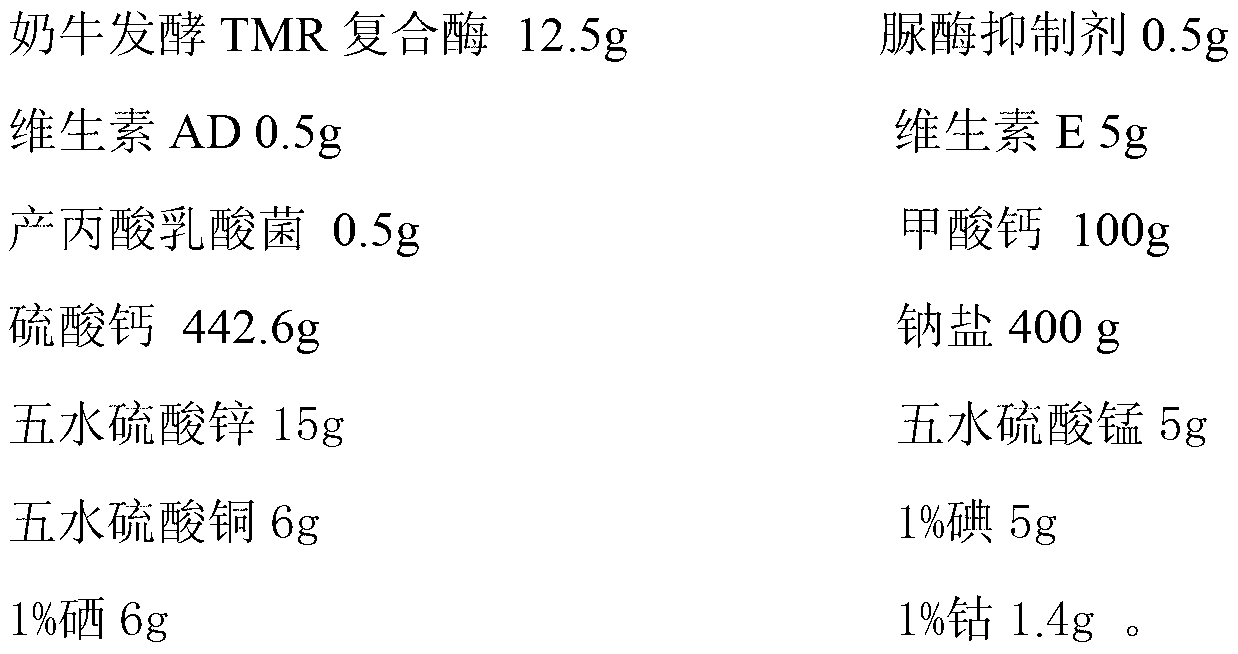

Embodiment 1~7

[0065]

[0066] Mix the components in the above-mentioned Examples 1 to 7 uniformly in a mixer according to a conventional method to obtain the premix specially used for fermenting TMR of the present invention, and all the above are parts by weight.

[0067] Each group of raw materials in the above-mentioned embodiment is feed grade, and is conventional commercially available product, and information is as follows:

[0068] Dairy cow fermentation TMR compound enzyme: developed by Shanghai Dairy Cow Research Institute, produced by Fuyang Xingfa Biotechnology Co., Ltd.

[0069] Urease inhibitor: Institute of Animal Husbandry, Chinese Academy of Agricultural Sciences

[0070] VAD 3 1000: Adisseo Life Science Products (Shanghai) Co., Ltd.

[0071] VE: Adisseo Life Science Products (Shanghai) Co., Ltd.

[0072] Propionogenic Lactobacillus: Laman, France

[0073] Calcium formate: Shanghai Luyuan Fine Chemical Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com