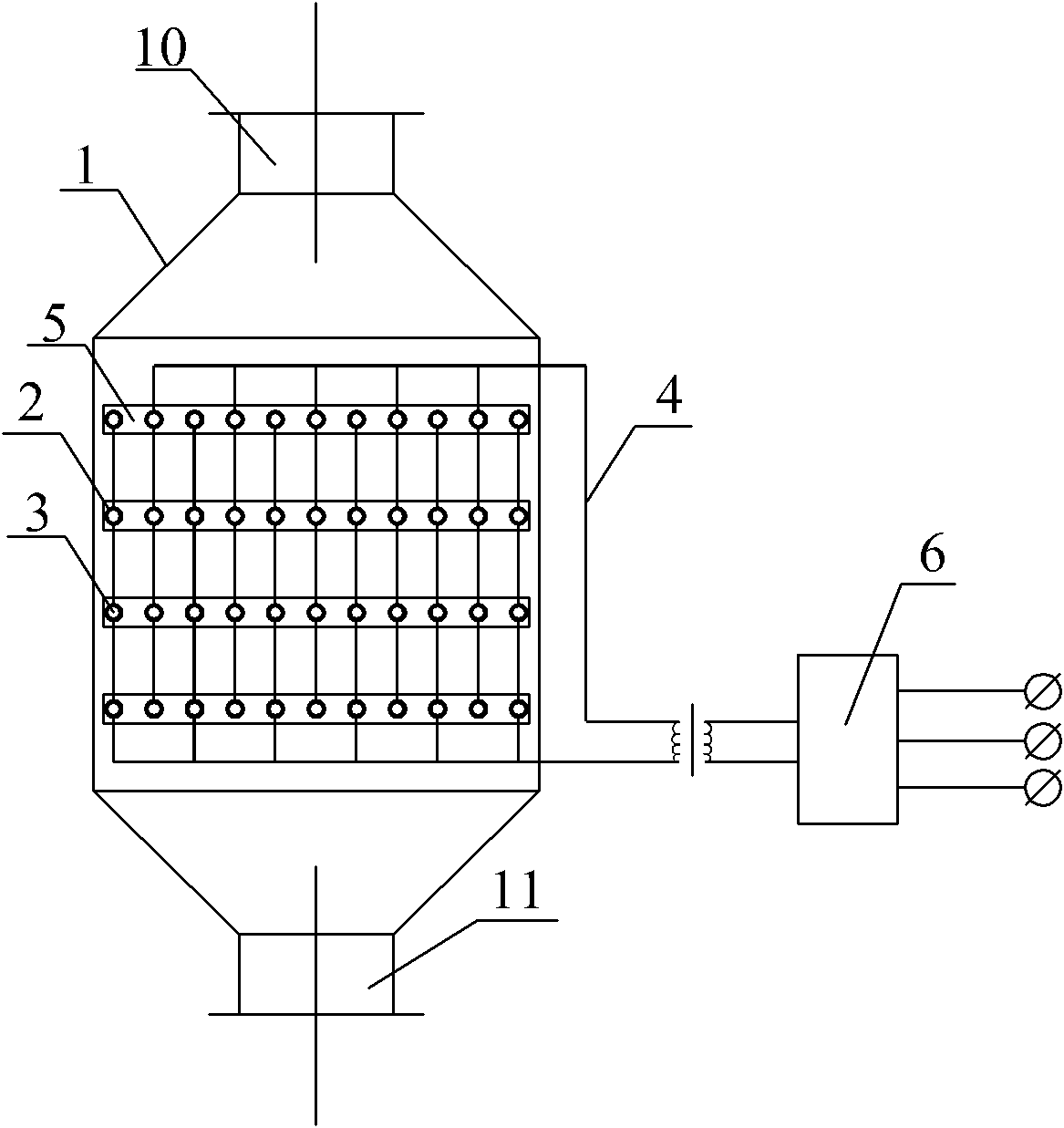

Matrix type dielectric barrier discharge plasma odor processing device

A dielectric barrier discharge and plasma technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of affecting gas flow, large gas resistance, and difficult application of discharge methods, and improve energy utilization. , high energy efficiency, the effect of the best pollutant removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

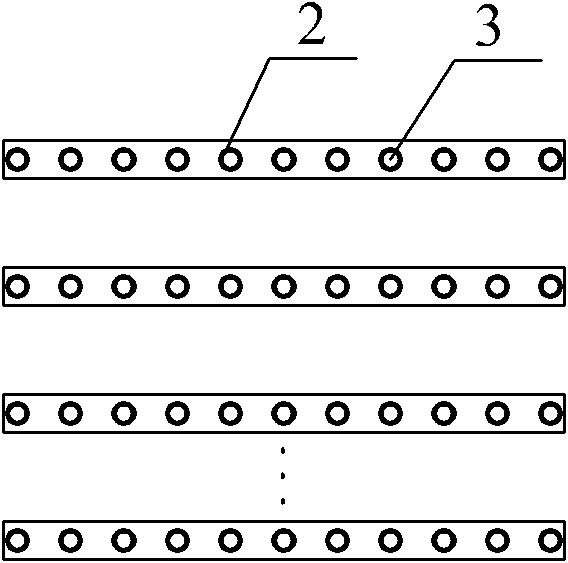

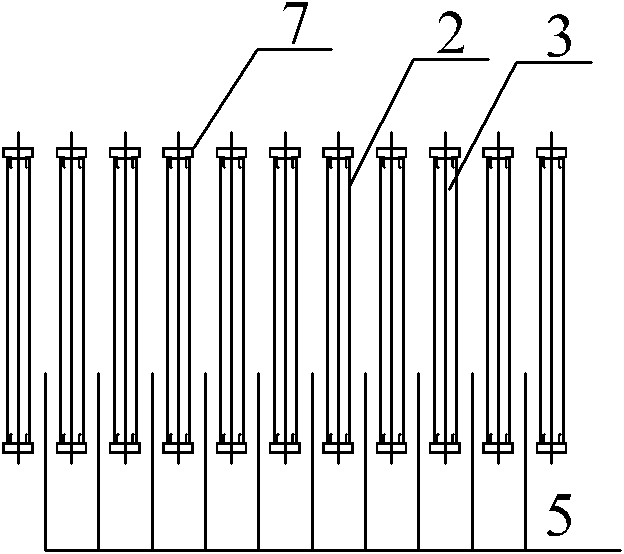

[0026] An induced draft fan is installed at the air outlet, under the action of the induced draft fan, the concentration is 178mg / m 3 H 2 After the gas is evenly distributed, the malodorous gas quantitatively enters each matrix dielectric barrier discharge plasma treatment device for odor gas. The treated gas is discharged through the chimney, and is sampled and analyzed at 1m from the outlet of the induced draft fan. In order to ensure the accuracy of sampling , the position of each sampling is fixed, and the sampling is performed after the reactor runs stably for 30 minutes.

[0027] Gas distribution: controlled by the rotameter of each branch, the flow rate is less than 500m 3 / h is adjustable.

[0028] Matrix dielectric barrier discharge plasma treatment device for odor gas: 5 sets, each specification parameter is the same as the above introduction, and the processing capacity of the whole system is 2500m 3 / h.

[0029] Induced fan: FRP centrifugal fan, Suzhou Dingyu E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com