Method for preparing composite anode material LiFePO4/C for lithium ion battery

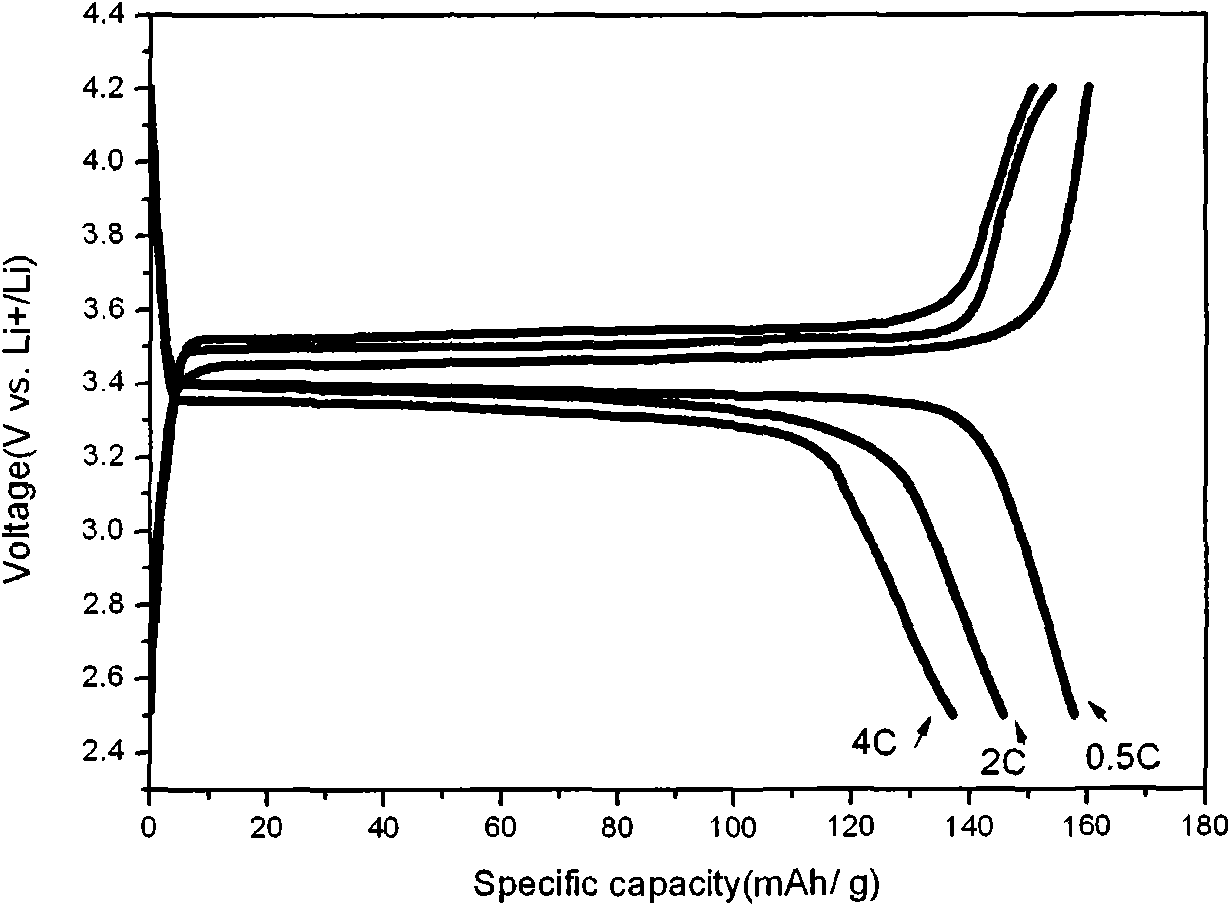

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of insufficient high rate discharge and insufficient uniformity of particles, and achieve a stable charge and discharge voltage platform, excellent performance, The effect of structural stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh 0.5mol lithium hydroxide, 0.65mol ferrous chloride, 0.70mol diammonium hydrogen phosphate and dissolve them in deionized water, then add 1.2mol resorcinol and 0.45mol polyethylene glycol to the mixed solution (PEG-2000), mix well. Measure the formaldehyde solution so that the molar ratio of formaldehyde to resorcinol is 2:1 and add it to the above solution. Stir continuously under a magnetic stirrer, stir at a constant temperature of 35°C for 6 hours, and adjust the pH value to about 8.9 with ammonia water, and form a sol after ultrasonic dispersion;

[0029]2) After drying the prepared sol at 160° C. for 5 hours, evaporate the solvent to obtain a xerogel;

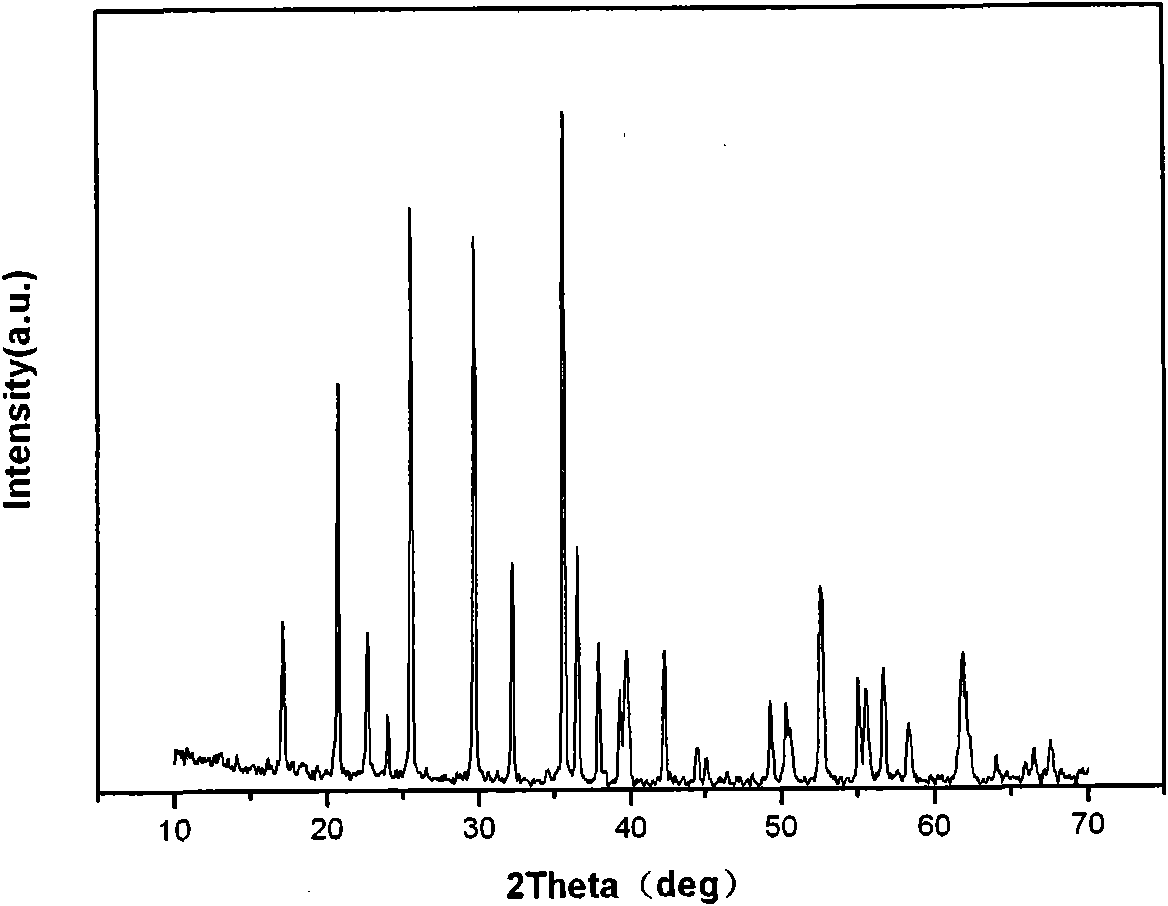

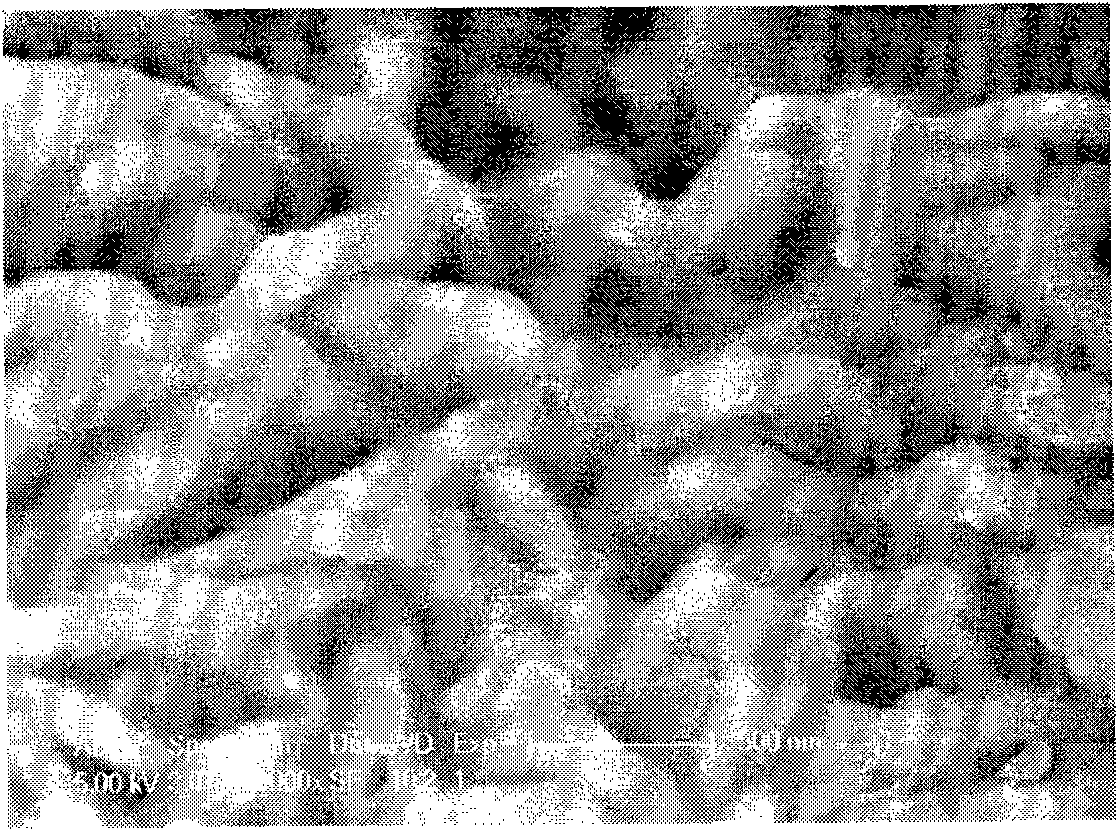

[0030] 3) Then ball mill for 6 hours on a planetary ball mill with a rotating speed of 600 rpm. Pre-fire at 380°C for 8 hours after fully grinding. Calcining at 700°C for 10 hours under the atmosphere of nitrogen and hydrogen (5%-10%), the gas flow rate is 0.1-10L / min. Cool down to room temperature to g...

Embodiment 2

[0034] 1) Weigh 0.75mol lithium chloride, 0.95mol ferrous oxalate, 0.80mol lithium phosphate, dissolve in deionized water, then add 1.56mol resorcinol and 0.65mol polyethylene glycol (PEG -2000), mix well. Measure the formaldehyde solution so that the molar ratio of formaldehyde to resorcinol is 2:1 and add it to the above solution. Stir continuously under a magnetic stirrer, stir at a constant temperature of 55°C for 5 hours, and adjust the pH value to about 4.2 with hydrochloric acid, and form a sol after ultrasonic dispersion;

[0035] 2) After drying the prepared sol at 120° C. for 9 hours, evaporate the solvent to obtain a xerogel;

[0036] 3) Then ball mill on a planetary ball mill for 10 hours at a speed of 500 rpm. Pre-fire at 450°C for 5 hours after fully grinding. Calcining at 900°C for 5 hours under an atmosphere of nitrogen and carbon monoxide (5% to 10%), with a gas flow rate of 0.1 to 10 L / min. Cool down to room temperature to get powdered LiFePO 4 / C Compos...

Embodiment 3

[0039] 1) Weigh 1.06mol of lithium acetate, 1.36mol of iron citrate, and 1.47mol of ammonium phosphate and dissolve them in deionized water, then add 2.52mol of resorcinol and 0.95mol of polyethylene glycol (PEG-2000 ),well mixed. Measure the formaldehyde solution so that the molar ratio of formaldehyde to resorcinol is 2:1 and add it to the above solution. Stir continuously under a magnetic stirrer, stir at a constant temperature of 80°C for 2 hours, and adjust the pH value to about 6.9 with different ratios of ammonia water and hydrochloric acid, and form a sol after ultrasonic dispersion;

[0040] 2) After drying the prepared sol at 90° C. for 20 h, evaporate the solvent to obtain a xerogel;

[0041] 3) Then ball mill for 3 hours on a planetary ball mill at a speed of 600 rpm. Pre-fire at 300°C for 10 hours after fully grinding. Calcining at 650°C for 10 hours under a protective atmosphere of nitrogen and hydrogen (5% to 10%), with a gas flow rate of 0.1 to 10 L / min. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com