Preparation method of molecularly imprinted polymer of methyltestosterone

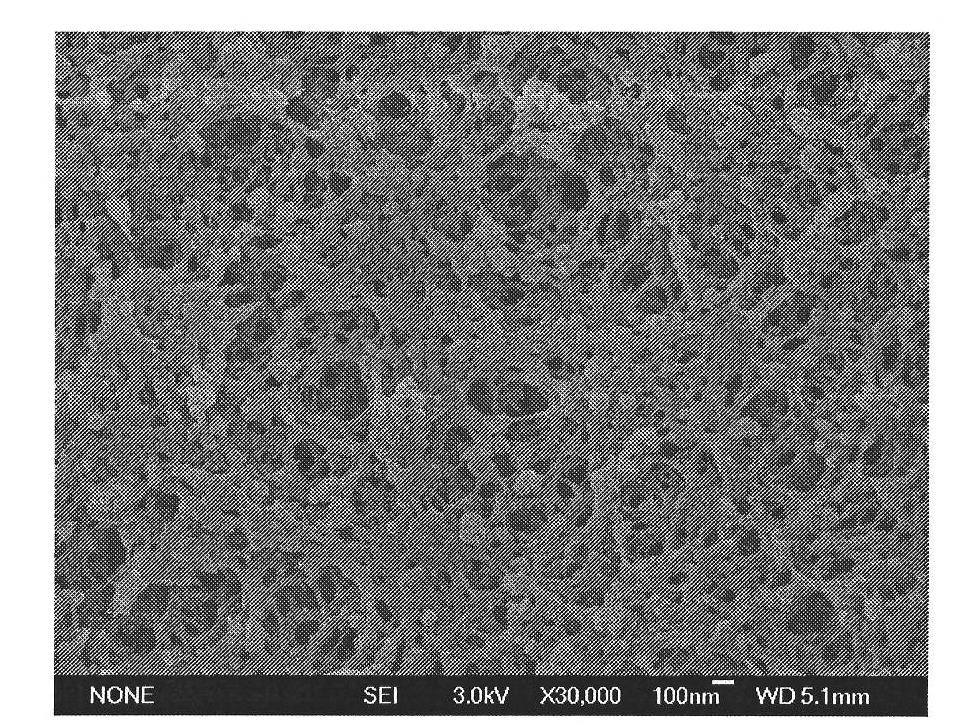

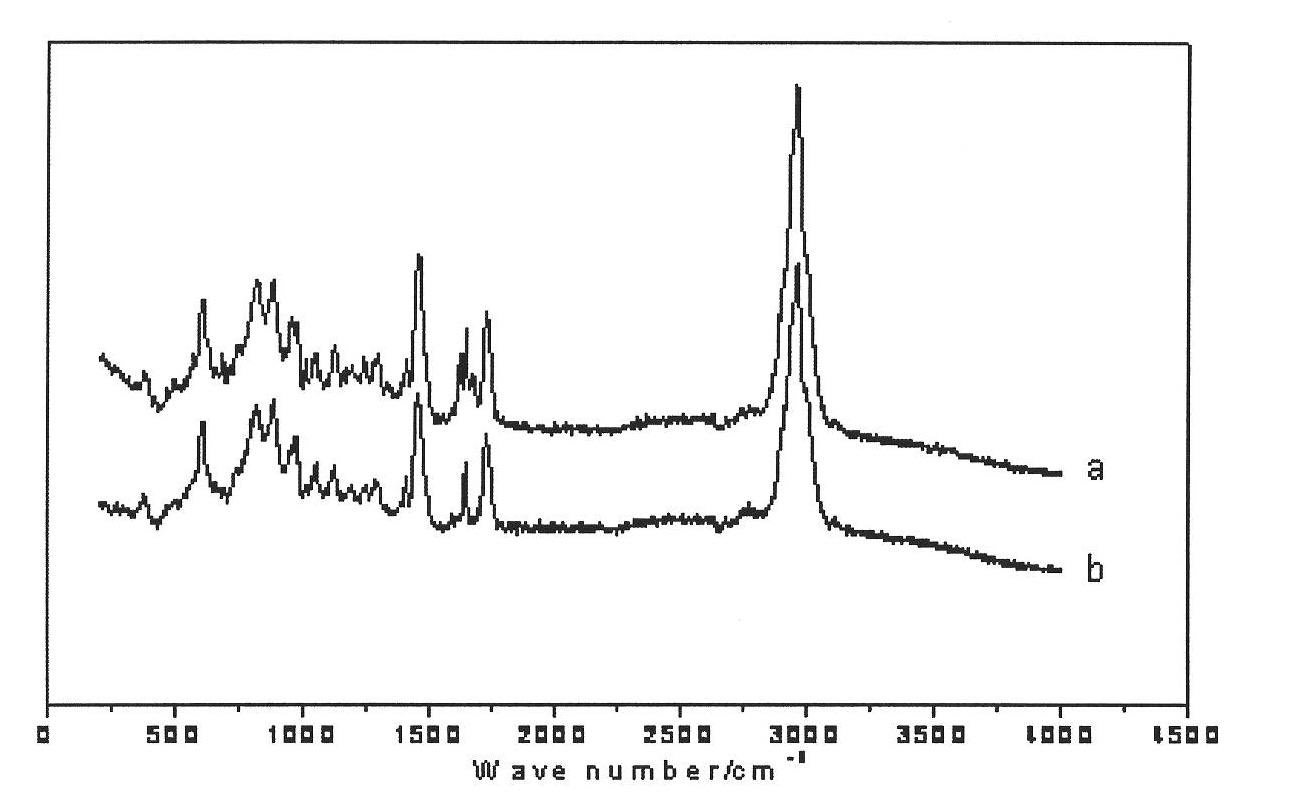

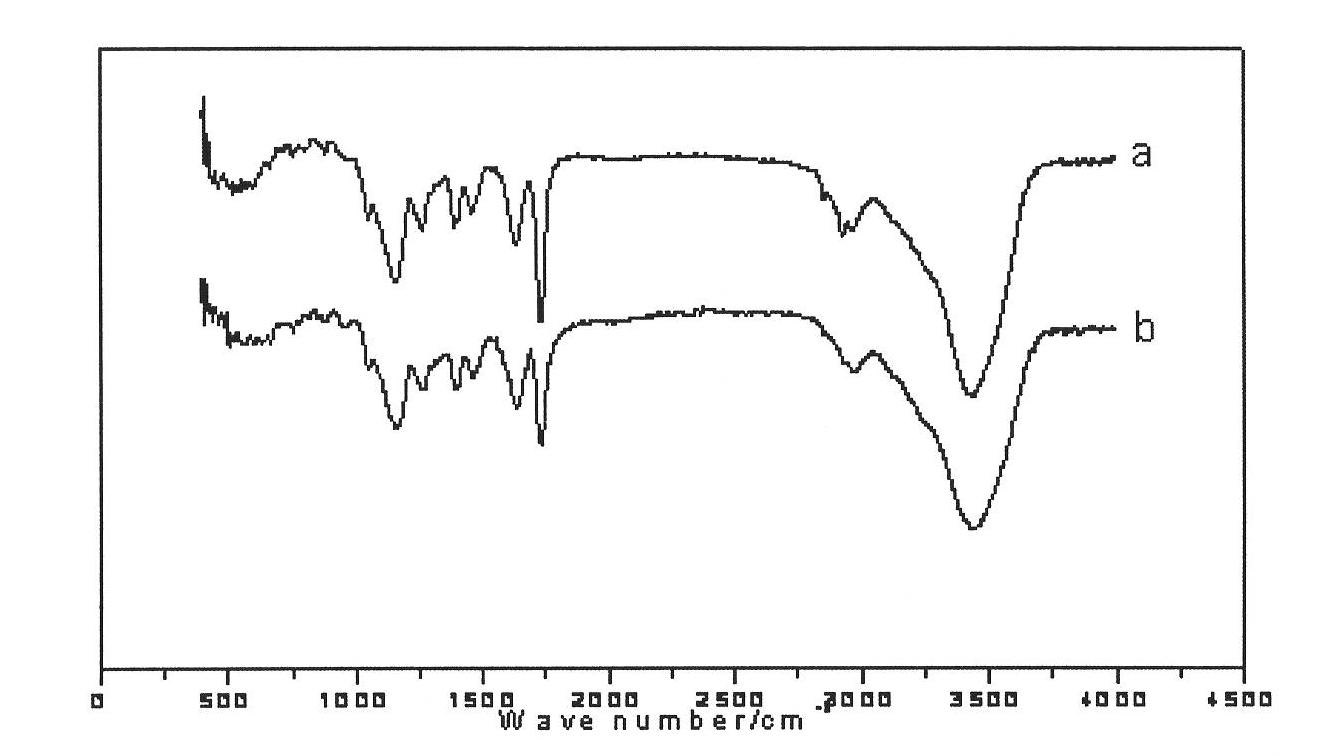

A technology of methyltestosterone and molecular imprinting, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of large loss, large specific surface area of molecularly imprinted polymers, and uneven particle size of polymers, so as to save costs, Good recognition ability and selection characteristics, the effect of overcoming uneven particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing a methyltestosterone molecularly imprinted polymer, comprising the steps of:

[0047] (1) Dissolving the template molecule methyltestosterone in the porogen acetonitrile at a ratio of about 60ml / mmol, then mixing it with the polymerized monomer methacrylic acid (MAA) at a ratio of 1:3, and shaking for 2 hours;

[0048] (2) Add cross-linking agent ethylene glycol dimethacrylate and initiator azobisisobutyronitrile (AIBN) to the product of step (1), mix well; dissolve the dispersant polyvinyl alcohol in 80°C water, the aqueous solution was added dropwise to the above mixed solution, and N 2 10min to remove O 2 , sealed and placed in a water bath at 60°C, stirred for 18 hours at the same time, solid-liquid separation, and the solid phase part was taken after high-speed centrifugation; wherein, the ratio of cross-linking agent to methyltestosterone was 1:20, and the ratio of initiator to methyltestosterone was 70mg / mmol, the ratio of dispersant to ...

Embodiment 2

[0057] (1) Dissolving the template molecule methyltestosterone in the porogen methanol at a ratio of about 6ml / mmol, then mixing it with the polymerized monomer acrylamide (AA) at a ratio of 1:8, and shaking for 4 hours;

[0058] (2) Add crosslinking agent trimethoxypropane trimethacrylate and initiator azobisisoheptanonitrile (ABVN) to the product of step (1), mix well; dissolve dispersant polystyrene in 100°C In the water, the aqueous solution was added dropwise to the above mixed solution, and argon was passed through for 10 minutes to remove O 2 Wait for oxygen-containing gas, seal and place in a water bath at 55°C, stir for 24 hours at the same time, separate solid and liquid, and take the solid phase part after high-speed centrifugation; wherein, the ratio of crosslinking agent to methyltestosterone is 1:30, and the ratio of initiator to methyltestosterone is 1:30. The ratio of testosterone is 40mg / mmol, and the ratio of dispersant to methyltestosterone is 5g / mmol.

[0...

Embodiment 3

[0064] (1) Dissolving the template molecule methyltestosterone in the porogen acetone at a ratio of about 30ml / mmol, then mixing it with the polymerized monomer trifluoromethacrylic acid (TFMAA) at a ratio of 1:5, and shaking for 0.5h;

[0065] (2) Add cross-linking agent and initiator azobisisobutyronitrile (AIBN) to the product of step (1), and mix well; dissolve the dispersant polystyrene in water at 90°C, and add the aqueous solution dropwise Into the above mixed solution, pass N 2 10min to remove O 2 Wait for oxygen-containing gas, seal it in a water bath at 65°C, stir for 30 hours at the same time, separate the solid from the liquid, and take the solid phase part after high-speed centrifugation; among them, the crosslinking agent is ethylene glycol dimethacrylate and trimethoxypropane trimethacrylate The mixture of methacrylate, the ratio of cross-linking agent and methyl testosterone is 1:10, the ratio of initiator and methyl testosterone is 100 mg / mmol, and the ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com